Horizontal automatic circulation tooling plate vertical conveyor

A vertical conveyor and automatic circulation technology, which is applied in the direction of storage, transportation and packaging, etc., can solve the problems of inability to carry out automatic management, consume physical strength of workers, and low transportation efficiency, so as to solve the problem of three-dimensional storage, improve fire safety, reduce artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

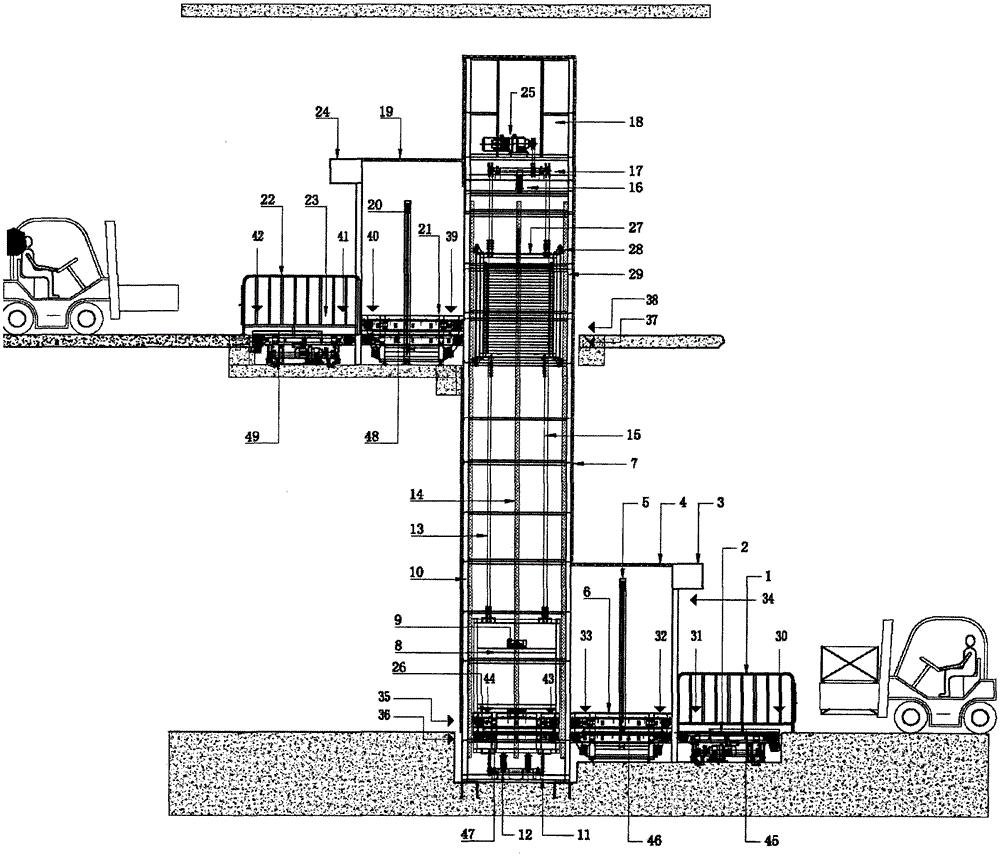

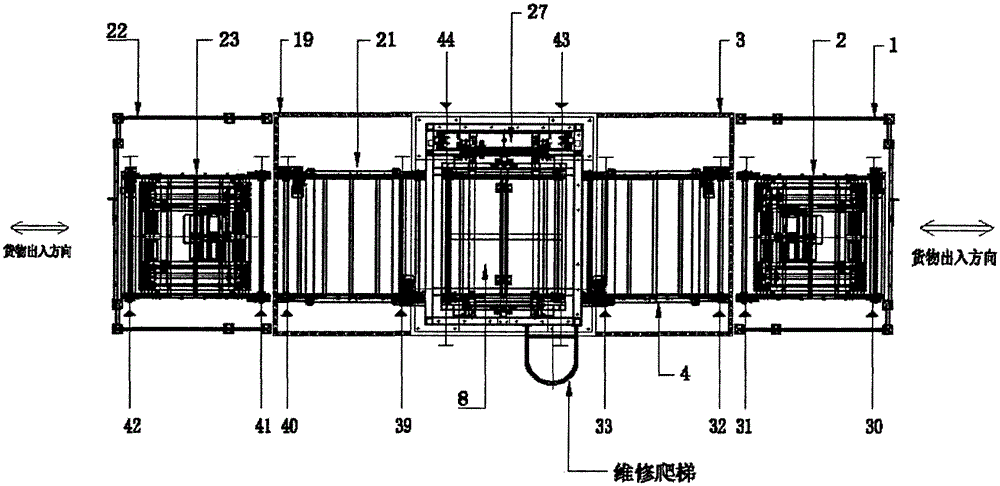

[0010] like figure 1 As shown in the figure, the horizontal automatic circulation tooling plate vertical conveyor of the present invention includes a first safety guardrail (1), a single-layer chain tooling plate lifting and conveying section A (2), a first fire shutter door (3), a first A fire partition (4), a first ultra-high and ultra-wide detection frame (5), a double-layer chain tooling plate conveying section A (6), a fireproof plate (7), a car (8), and a car guide wheel assembly (9) , frame (10), bottom driven sprocket (11), bottom anti-collision device (12), vertical conveying drive chain (13), car guide rail (14), vertical conveying drive chain (15), top anti-collision Device (16), top driving sprocket (17), top maintenance room (18), second fire partition (19), second ultra-high and ultra-wide inspection frame (20), double-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com