Special equipment and method for diffusing antimony latex source buried layer

A special equipment, layer diffusion technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large process compatibility, large transistor saturation voltage drop, complex process, etc., to optimize the buried layer Diffusion technology, small relative deviation, easy process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

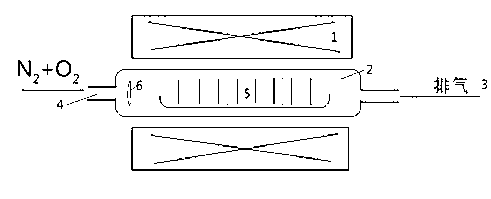

[0029] Diffusion high-temperature furnace 1 has three-zone temperature control with an accuracy of ±0.5°C. The purpose of the thermal diffusion process is to achieve a predetermined impurity concentration distribution through high-temperature heat treatment, which is characterized by the directly measurable sheet resistance and junction depth. For a certain diffusion method, in order to obtain the required sheet resistance and junction depth, it is mainly determined by the diffusion Process conditions: diffusion temperature, time, protective atmosphere and flow rate. After the technical conditions are determined by theoretical estimation and a large number of process tests, they are strictly controlled and implemented in mass production.

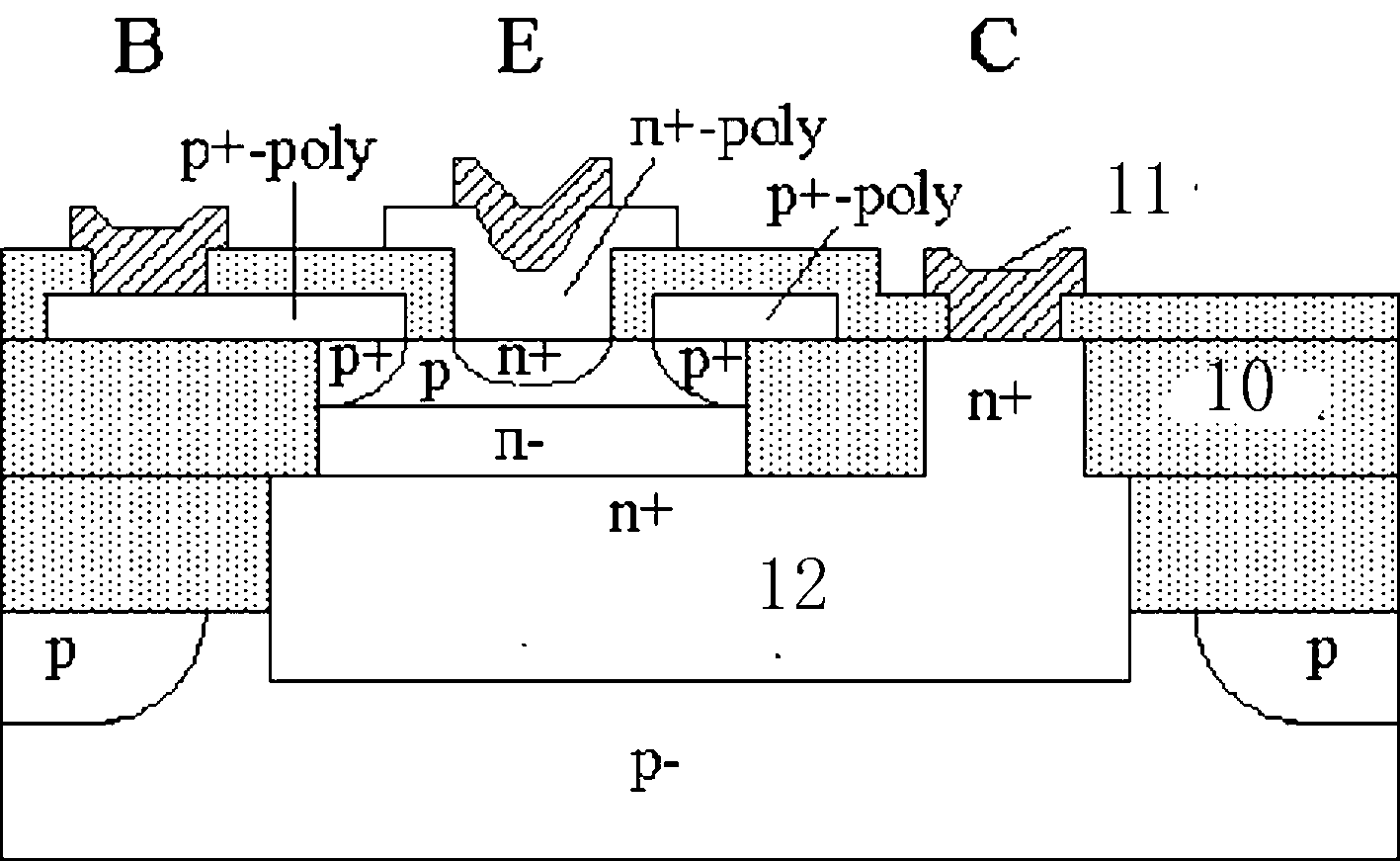

[0030] The present invention can use commercially available spectroscopically pure copolymerized type antimony latex impurity source (high-purity latex, dehydrated alcohol and antimony trioxide mixture), in 4 inch P-type single crystal silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com