Straight waveguide phase modulator

A phase modulator and straight waveguide technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of increased coupling process complexity, unfavorable signal processing, and decreased processing efficiency, so as to improve system reliability and improve production Effect of improving processing efficiency and degree of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

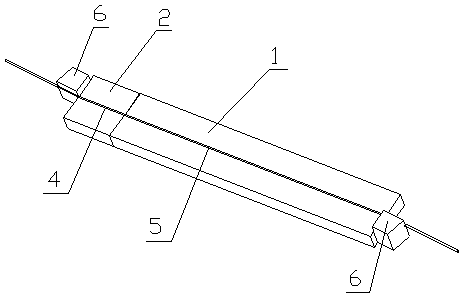

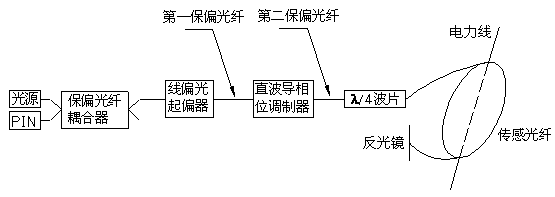

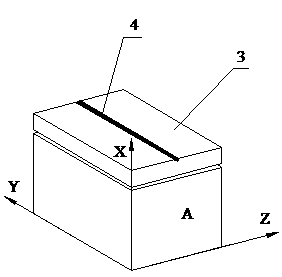

[0016] A direct waveguide phase modulator, comprising a titanium diffused lithium niobate phase modulator 1, the input end face of the titanium diffused lithium niobate phase modulator 1 is coupled and bonded to the end face of a lithium niobate polarizer chip 2; The lithium niobate polarizer chip 2 is composed of a lithium niobate wafer 3 and a polarizing waveguide 4 formed on its surface by a proton exchange annealing process, the surface of the structure where the polarizing waveguide 4 is located forms a first waveguide surface, The polarizing angle of the polarizing waveguide 4 to the input light is at an angle of 45° to the first waveguide surface, and the surface of the structure where the phase modulation waveguide 5 on the titanium-diffused lithium niobate phase modulator 1 is located forms the second waveguide surface, and the first waveguide face is flush with the second waveguide face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com