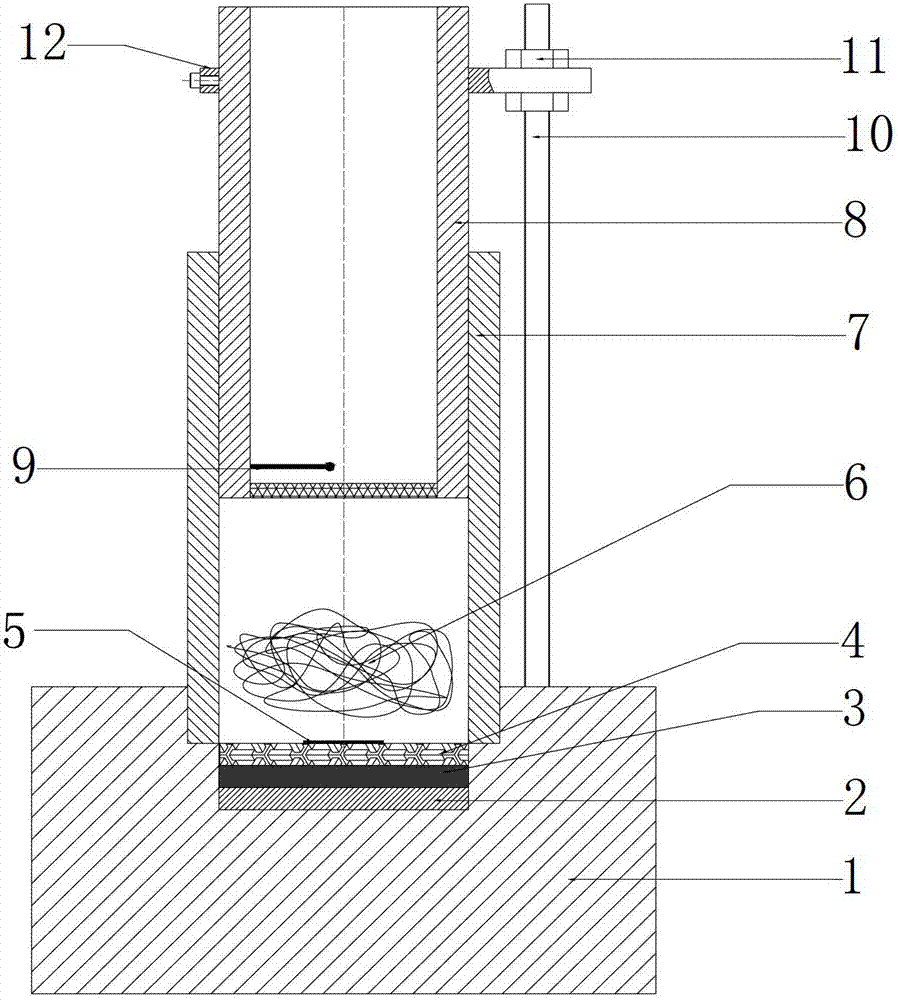

Measurement apparatus of heat transfer performance of wadding-filled fiber aggregates

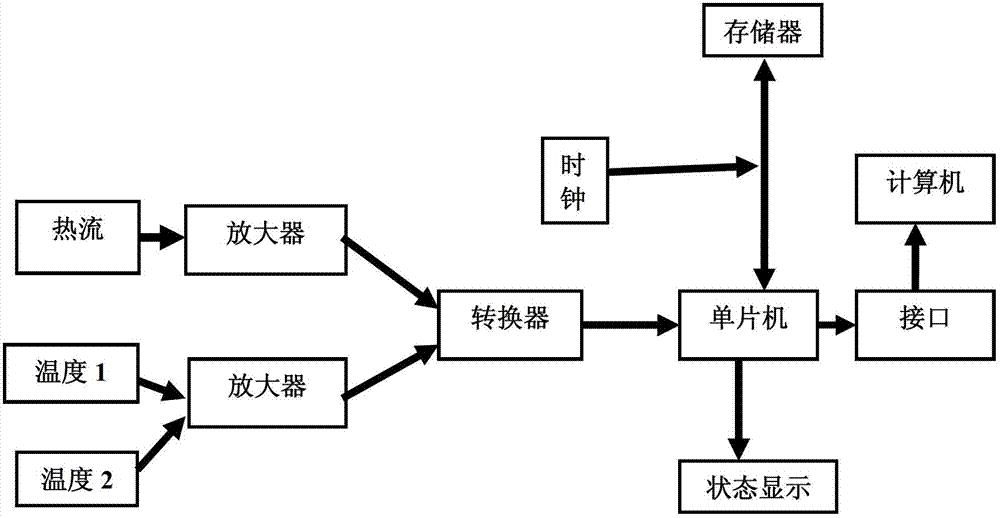

A technology of fiber aggregates and measuring devices, which is applied in the field of measuring devices for thermal insulation performance and heat transfer performance of flocculated fiber aggregates. The effect of simplification, simple device structure and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

[0043] The following examples will help to understand the present invention, but do not limit the protection scope of the present invention.

[0044] In order to ensure the accuracy and sensitivity of the measuring device and ensure that the error of the measured data does not exceed the specified range, it is necessary to check the displayed value of the measuring device and the standard value first. The signals from the first and second temperature sensors are transformed into temperature, and the temperature is calibrated with the wet-bulb thermometer under standard atmospheric conditions as the standard temperature, and the error after calibration is not greater than 0.1°C. The stability of the heating power of the device is judged to be in a stable state when the difference between the thermal resistance values of four consecutive readings does not exceed 1% within the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com