The Design Method of the Center Wheel Tooth Shape of the Nutating Movable Gear Transmission Mechanism

A technology of movable tooth transmission and design method, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., and can solve problems such as uncertain ball movement and reduced transmission meshing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

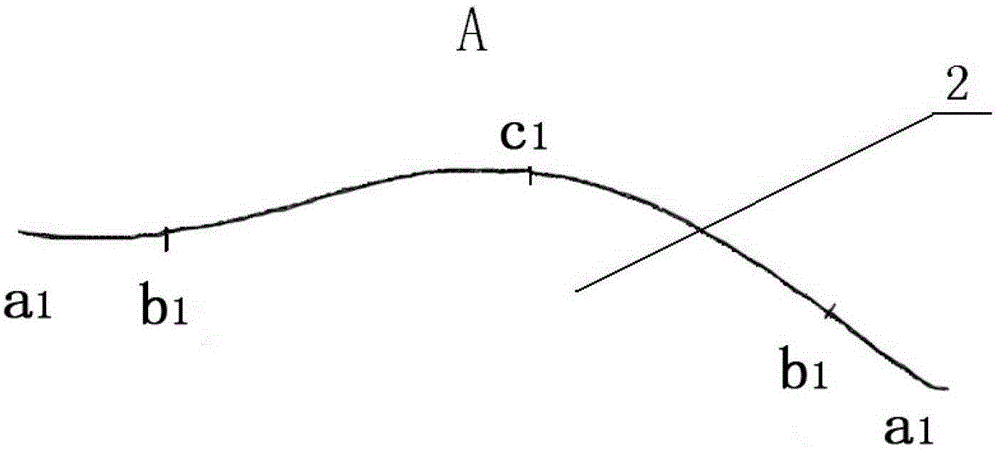

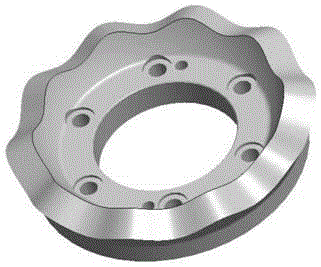

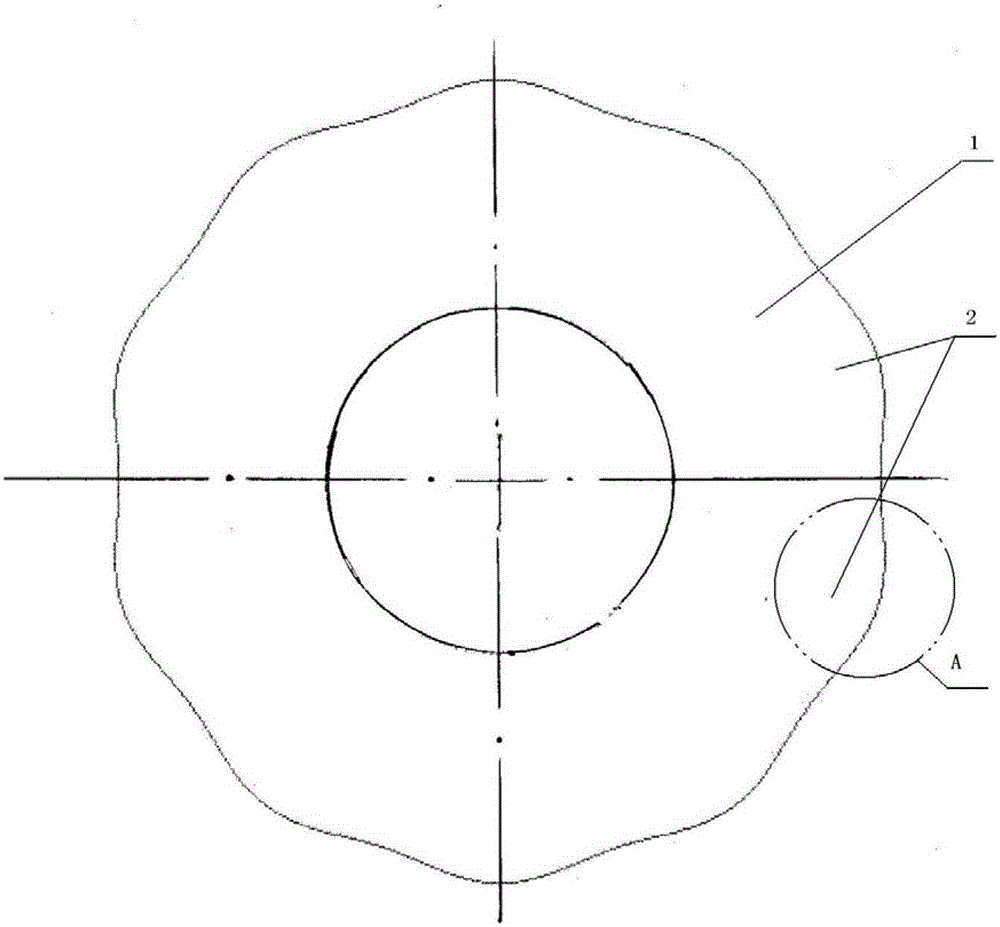

[0036] figure 1 , 2 , 3, 4, 5, 6, 7, and 8 show specific embodiments of the present invention, which are the center wheel tooth shape of the nutating movable tooth transmission mechanism combined with the roller bevel movable tooth, including the central wheel, and its characteristics That is: the tooth shape of the center wheel 1 adopts a spherical arc curve tooth shape, and each single tooth 2 tooth shape is composed of two symmetrical hemispherical circular curves, and each hemispherical circular curve is formed by the tooth root point a 1 and cut point b 1 between a 1 b 1 Arc curve, tangent point b 1 and tooth apex c 1 between b 1 c 1 It is composed of circular curves, and the junction of the adjacent two circular curves transitions smoothly into an overall smooth spherical arc curve tooth shape.

[0037] The design method of the center wheel tooth profile of the nutating movable tooth transmission mechanism is characterized in that: the steps of the design metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com