A method for enriching Monascus by using retrograded starch

A technology of retrograding starch and Monascus, which is applied in the field of enriching Monascus by using retrograded starch, which can solve the problems of difficulty in strain separation and increase the workload of strain separation, and achieve the effect of less miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

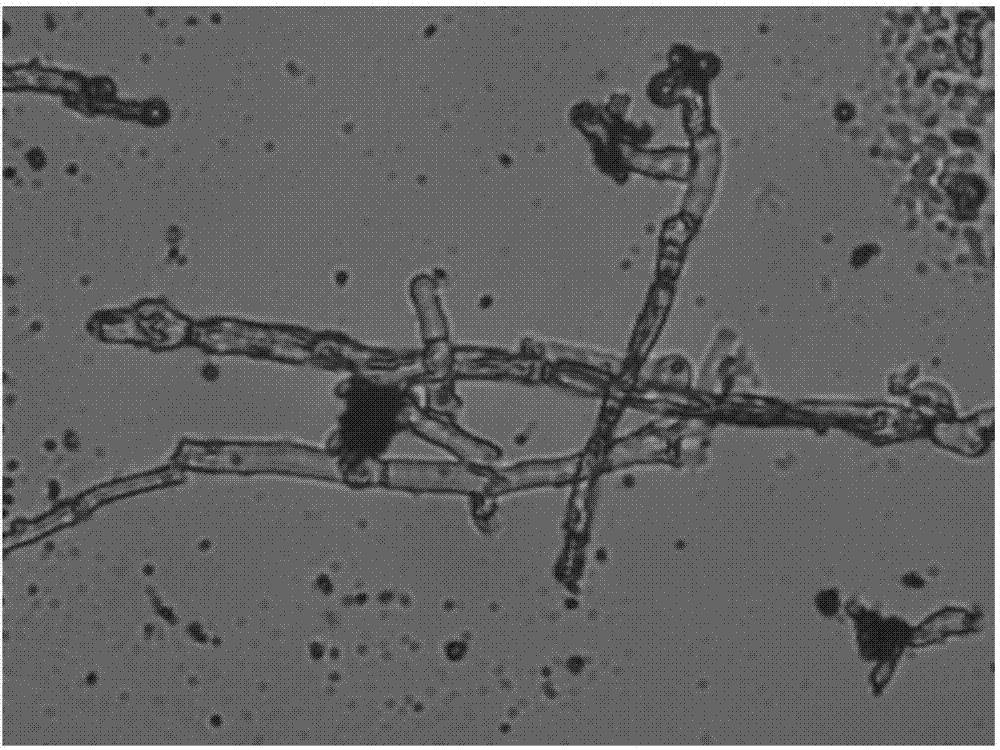

[0019] Corn starch was dissolved in water to obtain a starch emulsion with a concentration of 10% by mass, and the starch emulsion was gelatinized at 90°C for 30 minutes, followed by high-pressure treatment to obtain starch paste. The temperature of the high pressure treatment is 120° C., and the time of the high pressure treatment is 60 minutes. Afterwards, it was aged at 4°C for 96 hours to obtain gelatinous retrograded starch. Put the colloidal retrograded starch in the air with an outdoor temperature of -15°C and a wind speed of 5-15 m / s. The retrograded starch will freeze, and the water in it will slowly gasify. Monascus spores in the air will be blown into the starch, and the starch will enrichment and growth. The result of enrichment is as figure 1 shown.

[0020] Grind the above solid red starch with Monascus into powder and put it into sterile water to make a bacterial suspension, and apply the bacterial suspension to the mold solid medium (5% soluble starch, 4% ma...

Embodiment 2

[0022] Dissolve sweet potato starch in water to obtain a starch emulsion with a mass percentage of 15%, gelatinize the starch emulsion at 90°C for 30 minutes, and then perform high-pressure treatment to obtain starch paste. The temperature of the high-pressure treatment is 120°C, and the time of high-pressure treatment is 60 minutes. . Afterwards, it was aged at 4°C for 96 hours to obtain gelatinous retrograded starch. Put the colloidal retrograded starch in the air with an indoor temperature of -28°C, artificially blow the wind at a wind speed of 5-15 m / s, the retrograded starch will freeze, the water in it will slowly vaporize, and the Monascus spores in the air will be blown into In starch, enrich and grow in starch.

[0023] Grind the solid red starch with Monascus into powder and put it into sterile water to make a bacterial suspension, and apply the bacterial suspension to the mold solid medium (5% soluble starch, 4% maltose, 3% peptone, agar 2%, others are water), cul...

Embodiment 3

[0025] Dissolve potato starch in water to obtain a starch emulsion with a mass percentage of 13%, gelatinize the starch emulsion at 90°C for 30 minutes, then perform high-pressure treatment to obtain starch paste, the temperature of the high-pressure treatment is 120°C, and the time of high-pressure treatment is 60 minutes ; After that, aged at 4°C for 96h to obtain colloidal retrograded starch. Put the colloidal retrograded starch outdoors, artificially blow the air, the air temperature is -15°C, the wind speed is 5-15 m / s, the retrograded starch is frozen, the water in it is slowly vaporized, and the Monascus spores in the air are blown into the starch , enrich and grow in starch.

[0026] Grind the solid red starch with Monascus into powder and put it into sterile water to make a bacterial suspension, and apply the bacterial suspension to the mold solid medium (5% soluble starch, 4% maltose, 3% peptone, agar 2%, others are water), cultivated at 32°C for 5-7 days, a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com