Preparation method for temperature-sensitive hydrogel/silver nanocomposite

A composite material and sensitive technology, applied in botany equipment and methods, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Solve the problems of low silver content, achieve the effects of improving swelling performance and heat resistance, good biocompatibility, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

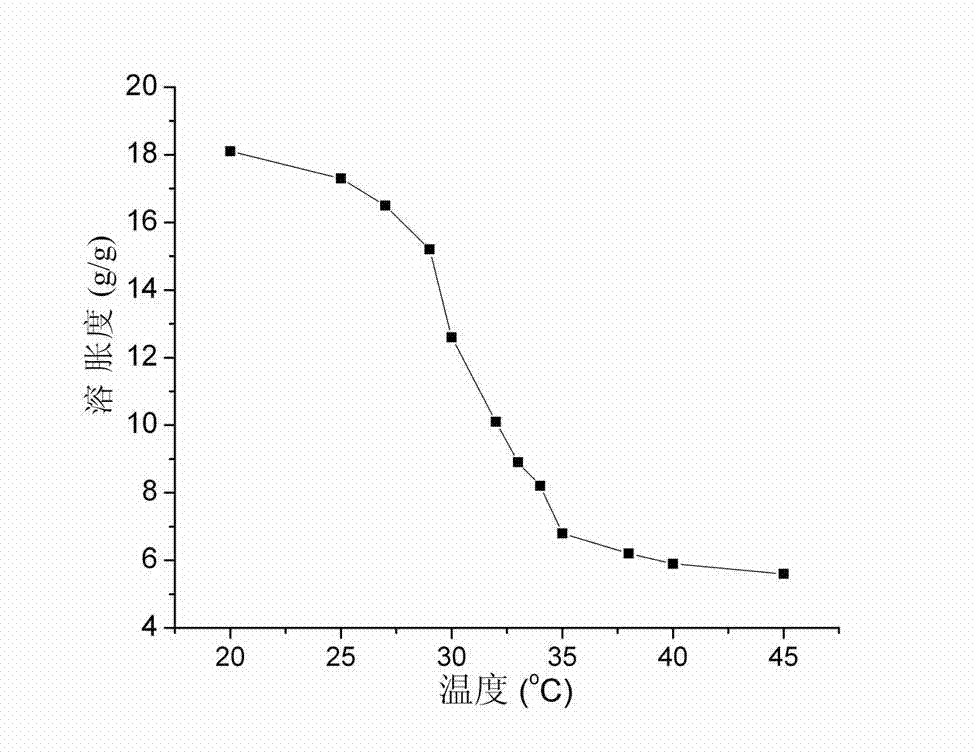

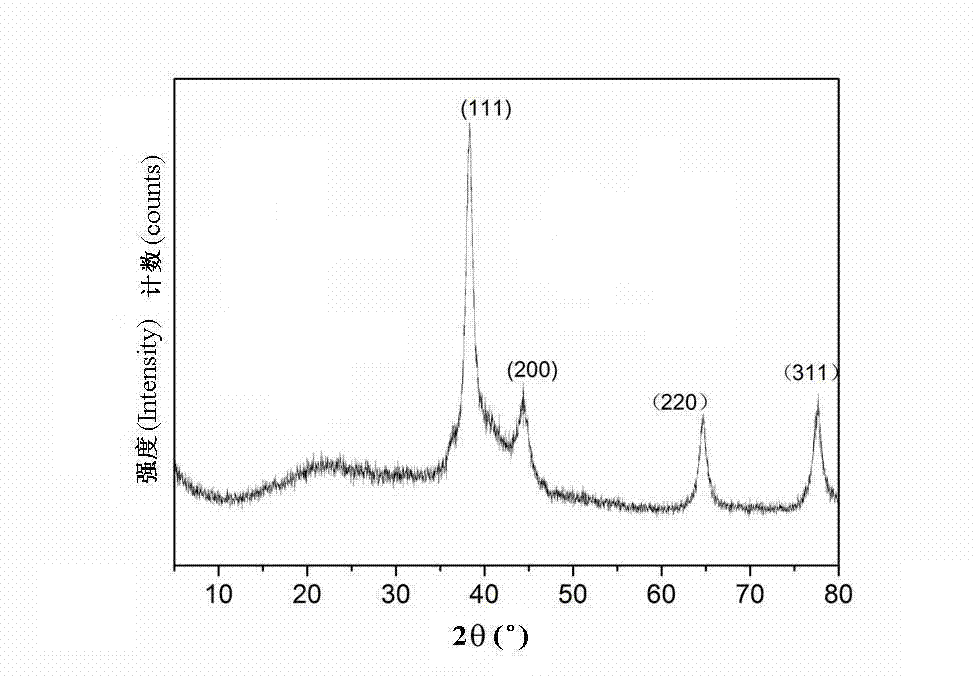

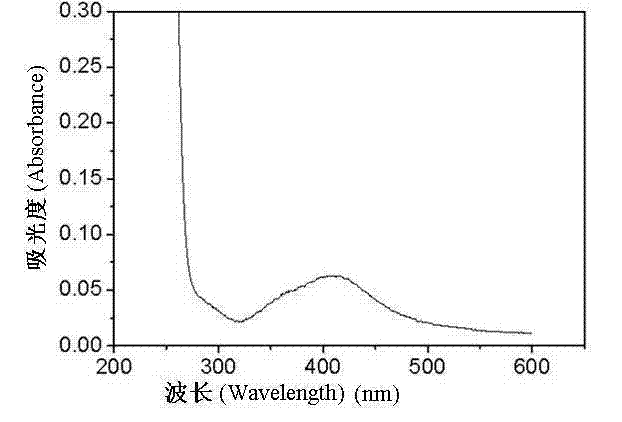

[0023] Dissolve 1.0 g of chitosan in 50 ml of 4% acetic acid solution and stir for 2 hours to dissolve it completely. Add 2.0 g of N-isopropylacrylamide, a temperature-sensitive monomer, and 0.15 g of methylenebisacrylamide, a chemical cross-linking agent, into the above solution under stirring conditions, and continue stirring for 30 minutes to prepare an aqueous reactant solution. Add 10ml of 1% initiator potassium persulfate aqueous solution to the above reactant solution, blow nitrogen, heat up to 60 degrees Celsius under constant stirring, and react for 4 hours. The product is washed with absolute ethanol and distilled water to remove unreacted monomers. and a crosslinking agent, and dry in a vacuum oven to obtain a white chitosan grafted N-isopropylacrylamide hydrogel. The dried hydrogel was fully swollen in distilled water for 1 day, transferred to 50ml of silver nitrate solution with a concentration of 5mmol / L and continued to soak for 24 hours, adding 10ml of the redu...

Embodiment 2

[0026] Dissolve 2.0 g of chitosan in 50 ml of 6% acetic acid solution and stir for 1 to 5 hours to completely dissolve it. Add 4.0 g of N-isopropylacrylamide, a temperature-sensitive monomer, and 0.2 g of methylenebisacrylamide, a chemical crosslinking agent, into the above solution under stirring conditions, and continue stirring for 30 minutes to prepare an aqueous solution of reactants. Add 10 ml of 2% initiator potassium persulfate aqueous solution to the above reactant solution, blow nitrogen, heat up to 60 degrees Celsius under constant stirring, and react for 6 hours. The product is washed with absolute ethanol and distilled water to remove unreacted monomers. and a crosslinking agent, and dry in a vacuum oven to obtain a white chitosan grafted N-isopropylacrylamide hydrogel. The dried hydrogel was fully swelled in distilled water for 2 days, transferred to 100ml concentration of silver nitrate solution of 5mmol / L and continued to soak for 24 hours, adding 40ml concentr...

Embodiment 3

[0029] Dissolve 5.0 g of chitosan in 200 ml of 10% acetic acid solution and stir for 5 hours to dissolve it completely. Add 6.0 g of N-isopropylacrylamide, a temperature-sensitive monomer, and 0.5 g of methylenebisacrylamide, a chemical cross-linking agent, into the above solution under stirring conditions, and continue stirring for 30 minutes to prepare an aqueous reactant solution. Add 10 ml of 3% initiator potassium persulfate aqueous solution to the above reactant solution, blow nitrogen, heat up to 60 degrees Celsius under constant stirring, and react for 8 hours. The product is washed with absolute ethanol and distilled water to remove unreacted monomers. and a crosslinking agent, and dry in a vacuum oven to obtain a white chitosan grafted N-isopropylacrylamide hydrogel. The dried hydrogel was fully swelled in distilled water for 2 days, transferred to 150ml concentration of silver nitrate solution of 5mmol / L and continued to soak for 24 hours, adding 60ml concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com