Silicic acid mud interior wall decorating material and preparation method thereof

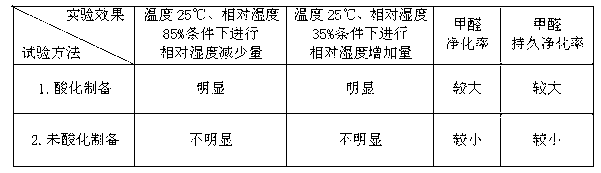

A decorative material and silicate mud technology, which are applied in the field of silicate mud interior wall decorative materials and their preparation, and can solve the problem of poor texture, inability to meet the requirements of decorative effect and air quality, and lack of air humidity adjustment and lasting purification effects. and other problems, to achieve the effect of eliminating odor, good interior wall decoration effect, and improving activation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

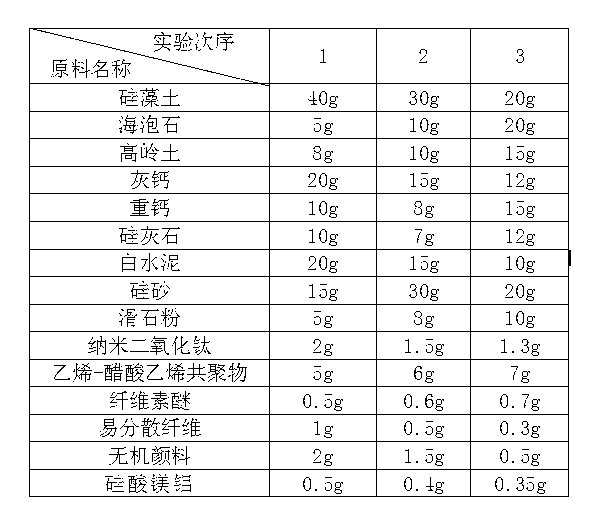

[0042] Embodiment 1, specific formula: 500 grams of diatomite, 50 grams of sepiolite, 50 grams of kaolin, 100 grams of lime calcium, 50 grams of heavy calcium, 50 grams of wollastonite, 50 grams of white cement, 50 grams of silica sand, talcum powder 50 grams, 5 grams of nano-titanium dioxide, 10 grams of ethylene-vinyl acetate copolymer, 1 gram of cellulose ether, 1 gram of magnesium aluminum silicate, 1 gram of easily dispersible fiber, and 5 grams of inorganic pigment.

Embodiment 2

[0043] Embodiment 2, specific formula: 100 grams of diatomite, 400 grams of sepiolite, 50 grams of kaolin, 100 grams of lime calcium, 50 grams of heavy calcium, 50 grams of wollastonite, 50 grams of white cement, 50 grams of silica sand, talcum powder 50 grams, 5 grams of nano-titanium dioxide, 10 grams of ethylene-vinyl acetate copolymer, 1 gram of cellulose ether, 1 gram of magnesium aluminum silicate, 1 gram of easily dispersible fiber, and 5 grams of inorganic pigment.

Embodiment 3

[0044] Embodiment 3, specific formula: 100 grams of diatomite, 50 grams of sepiolite, 200 grams of kaolin, 100 grams of lime calcium, 50 grams of heavy calcium, 50 grams of wollastonite, 50 grams of white cement, 50 grams of silica sand, talcum powder 50 grams, 5 grams of nano-titanium dioxide, 10 grams of ethylene-vinyl acetate copolymer, 1 gram of cellulose ether, 1 gram of magnesium aluminum silicate, 1 gram of easily dispersible fiber, and 5 grams of inorganic pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com