Advanced treatment, regeneration and reuse device and method of domestic sewage from ships

A technology for advanced treatment and domestic sewage, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor impact load resistance, shortened membrane module replacement cycle, operation and maintenance Inconvenient and other problems, to achieve the effect of reducing equipment and solving the problem of insufficient ship capacity and load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

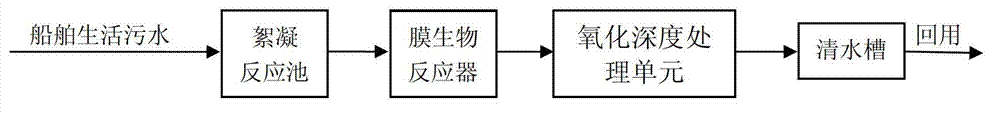

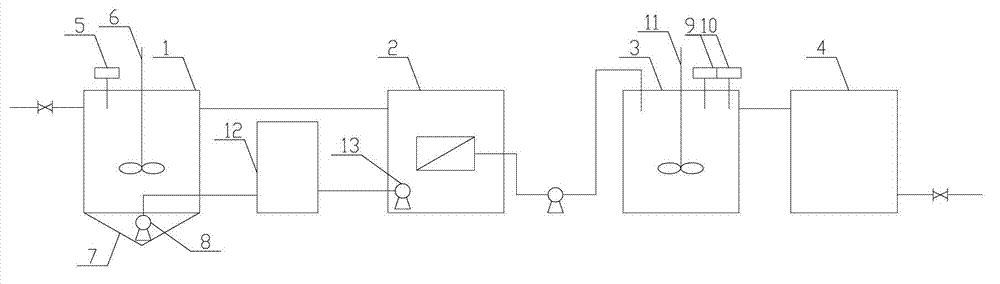

[0021] The method for advanced treatment and regeneration of ship domestic sewage in the present invention: ship domestic sewage flows into the flocculation reaction tank 1 through the sewage collection pipeline, and the coagulant is put into the flocculation reaction tank through the first dosing machine 5, and the coagulant and the ship The domestic sewage is contacted and coagulated by the first mixer 6 and then precipitated. The residence time of the sewage in this unit is 10 to 60 minutes. After reaching a certain height, the phosphorus-containing sludge is discharged to the sludge concentration tank 12 through the sludge discharge pump 8; the sewage enters the membrane bioreactor 2 after flocculation and sedimentation, and the membrane bioreactor adopts intermittent operation mode, and the self-priming pump operates 10-15min, stop the suction and backwash for 1-5min, the suction negative pressure range is 0.01-0.05MPa, the backwash pressure range is 0.05-0.2MPa, a small a...

Embodiment approach 2

[0023] Domestic sewage from ships flows into the flocculation reaction tank 1 through the sewage collection pipeline, and the coagulant polyferric chloride is put into the flocculation reaction tank through the first dosing machine 5, and the amount of the coagulant is such that the molar ratio of metal cations to total phosphorus is 0.7 : 1. The rapid contact mixing time of the coagulant and the ship's domestic sewage is 30s, the flocculation time is 30min, and the sedimentation time is 30min. The mechanical flocculation method is adopted. 6 is the first mixer, and the phosphorus-containing sludge after flocculation and sedimentation settles to the bottom In the sludge hopper 7, the phosphorus-containing sludge deposited in the sludge hopper reaches a certain height and is discharged to the sludge concentration tank 12 through the sludge discharge pump 8, and the sewage enters the membrane bioreactor 2 after flocculation and sedimentation, and the membrane bioreactor The devic...

Embodiment approach 3

[0025] The difference between this embodiment and the second embodiment is that the coagulant is one of polyaluminum chloride, magnesium chloride, calcium chloride, aluminum sulfate, magnesium sulfate, and ferrous sulfate, and the metal cation and the total phosphorus mole The ratio is 0.3-0.8:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com