Method for synthesizing iron-containing hydrotalcite-like compound by utilizing prussian blue as raw material

A Prussian blue and hydrotalcite technology, applied in the field of inorganic nanomaterial preparation, can solve the problems of limited improvement of single-component nano/microstructure performance, inability to meet the practical application requirements of supercapacitors, etc., and achieve good reversible discharge capacity and stable cycle. Performance, effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

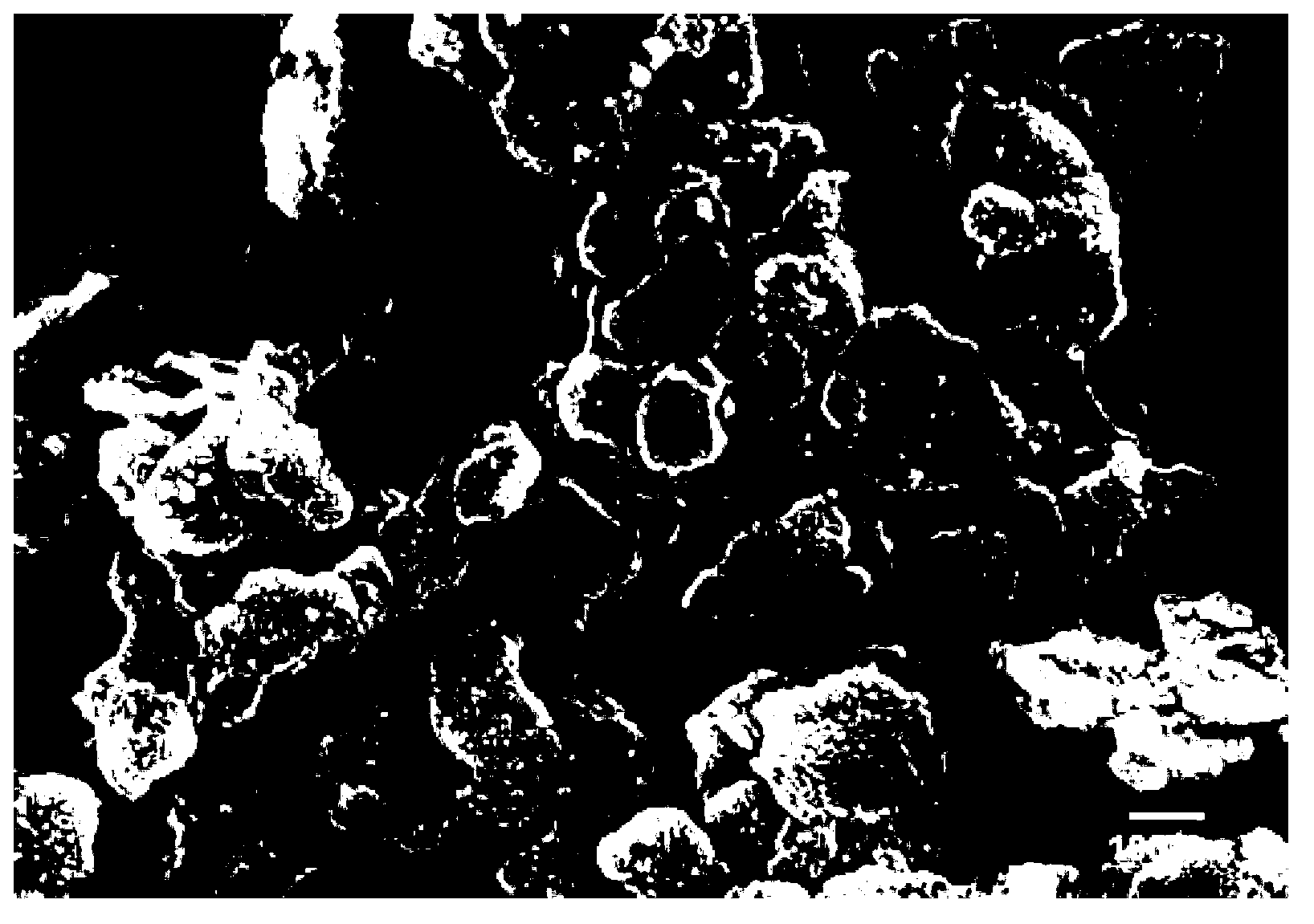

Image

Examples

Embodiment 1

[0016] A: Weigh 2g of Prussian blue powder, weigh 1.04g of formic acid according to the molar ratio of Prussian blue to formic acid is 1:3, dissolve the two in 100mL deionized water, stir and ultrasonicate for 30min to form a stable and uniform blue solution; Weigh 0.5gCo(NO 3 ) 2 ·6H 2 O was dissolved in the above blue solution, stirred and sonicated until dissolved;

[0017] B: Weigh NaOH and Na 2 CO 3 Dissolved in deionized water to form a mixed alkali solution, where n(NaOH) / [n(Co 2+ )+0.25n(Prussian blue)]=2.2, n(Na 2 CO 3 ) / [0.25n(Prussian blue)]=2.5, NaOH concentration is 1.5mol / L, n(NaOH), n(Co 2+ ), n (Prussian blue), n (NaCO 3 ) are the moles of sodium hydroxide, cobalt ions, Prussian blue, and sodium carbonate respectively, and the alkali solution is slowly added dropwise to the solution prepared in step A until the pH=9.5, then stirred and reacted at 80°C for 24 hours, and centrifuged and washed until the pH The value is 7, and then dried at 80°C for 40 ho...

Embodiment 2

[0019] A: Weigh 1.5g of Prussian blue powder, weigh 0.780g of oxalic acid according to the molar ratio of Prussian blue to oxalic acid is 1:5, dissolve the two in 100mL deionized water, stir and sonicate for 30min to form a stable and uniform blue solution , weighed 0.375gCo(NO 3 ) 2 ·6H 2 O was dissolved in the above blue solution, stirred and sonicated until dissolved;

[0020] B: Weigh NaOH and Na 2 CO 3 Dissolved in deionized water to form a mixed alkali solution, n(NaOH) / [n(Co 2+ )+0.25n(Prussian blue)]=3.0, n(Na 2 CO 3 ) / [0.25n(Prussian blue)]=2.5, NaOH concentration is 3.5mol / L, n(NaOH), n(Co 2+ ), n (Prussian blue), n (NaCO 3 ) are the moles of sodium hydroxide, cobalt ions, Prussian blue, and sodium carbonate respectively, and the alkali solution is slowly added dropwise to the solution prepared in step A until pH = 9, then stirred and reacted at 85°C for 24h, and centrifuged and washed until the pH The value is 8, and then dried at 140°C for 8 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com