Redistribution method of heavy doping boron silicon slice

A technology of heavy boron doping and redistribution, which is applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc., can solve the problems of increased preparation costs, limited use of temperature, and difficulty in high temperature for a long time , to achieve the effects of reducing the preparation time, reducing residual stress, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

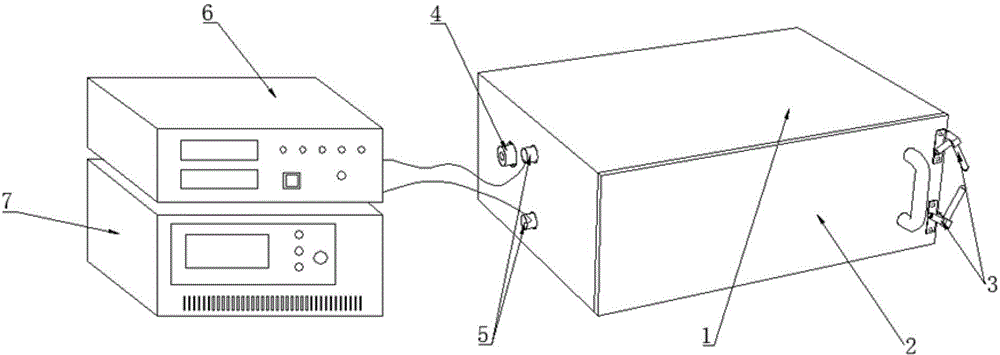

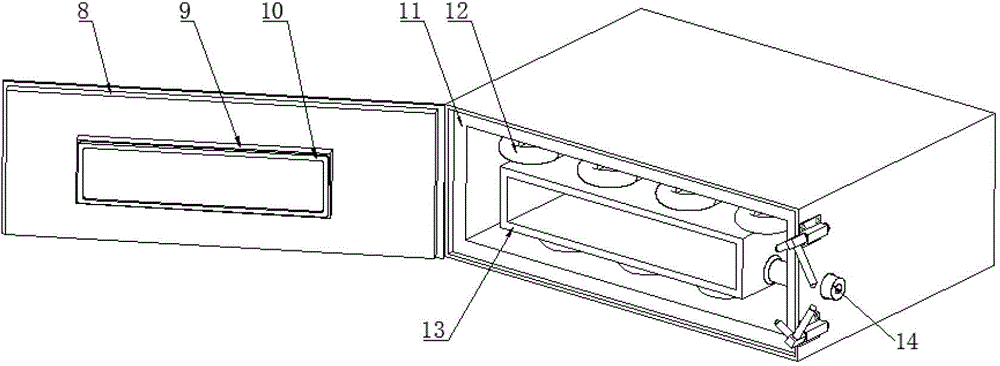

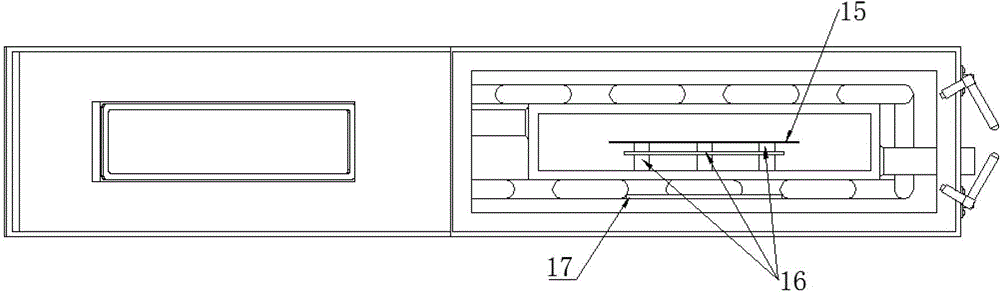

[0025] see Figure 1~3, the experimental device embodiment that the present invention adopts is provided with diffusion box, automatic matching device 6 and power supply 7, and described diffusion box is provided with shielding box shell 1, shielding box door 2, compression sealing mechanism 3, gas outlet 4, power supply interface 5. Screen door insulation layer 8, quartz door 9, sealing strip 10, heat preservation box 11, induction coil 12, quartz cavity 13, gas inlet 14, heavily doped borosilicate sheet 15, tray 16, electrode sheet 17 and An interference field strength meter (not shown in the figure), the power supply 7 includes a radio frequency power supply and an electric field power supply. Wherein, the shielding box shell 1 and the shielding box door 2 can be made of copper according to the shape shown in the figure. The specific positions of the gas outlet 4 and the inlet 14 in the box need to be determined according to the type of gas to be introduced. If the molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com