Liquid phase isoelectric focusing electrophoresis system

An electrophoresis system and electrofocusing technology, which are used in the separation of dispersed particles, chemical instruments and methods, and separation methods, etc., can solve the problem of reducing the sample yield of the liquid phase isoelectric focusing electrophoresis system, unstable and unallowable conductance at the entrance of the separation electric field. There are problems such as metal components, and the effect of improving heat diffusion efficiency, heat exchange efficiency and temperature uniformity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

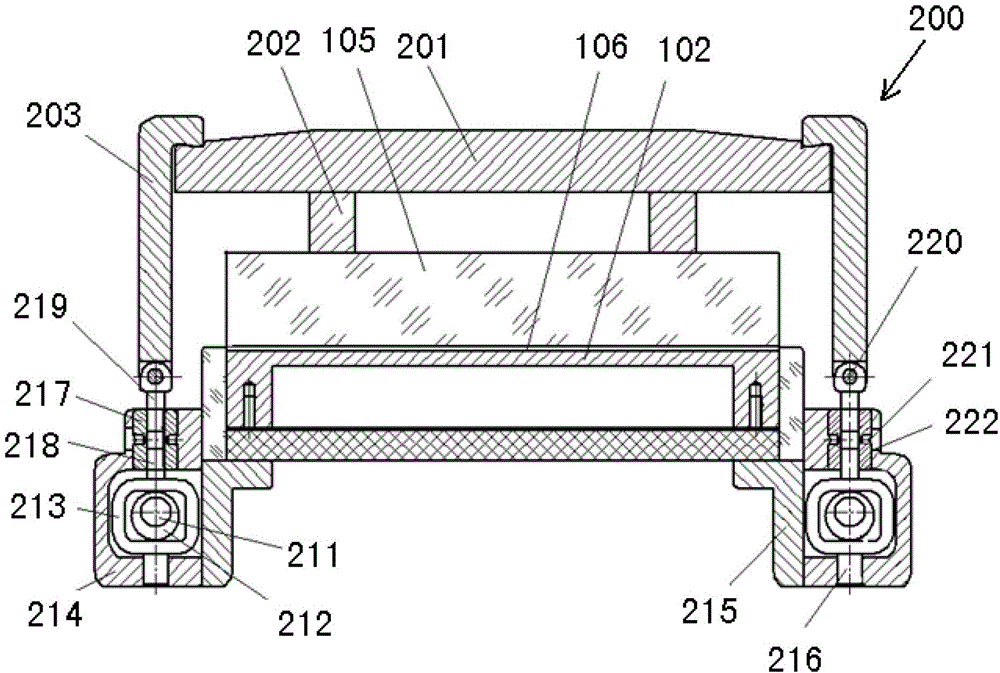

[0030] The present invention is an improvement to the free-flow electrophoresis system in the prior art, mainly making some improvements to the separation device 100, the compacting device 200 and the power supply device 300 in the system.

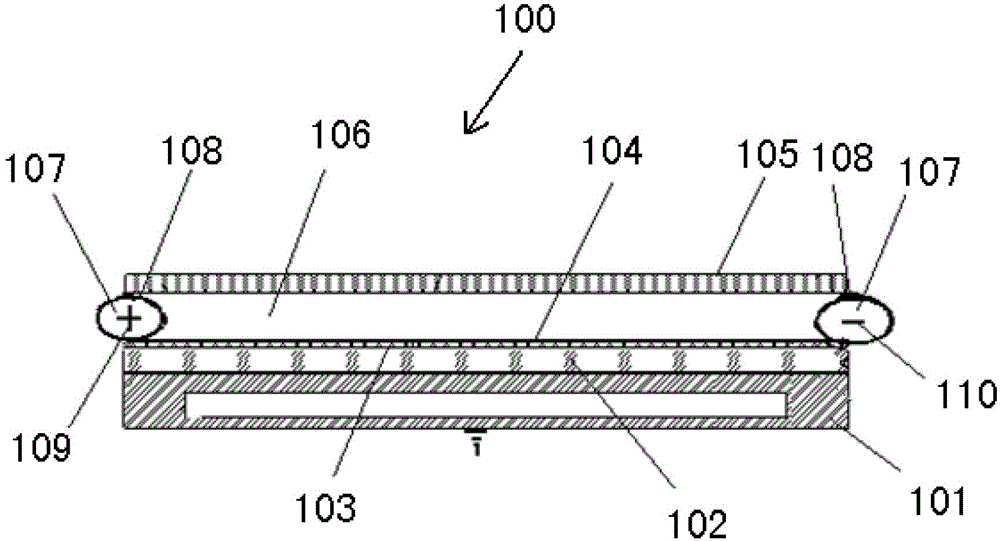

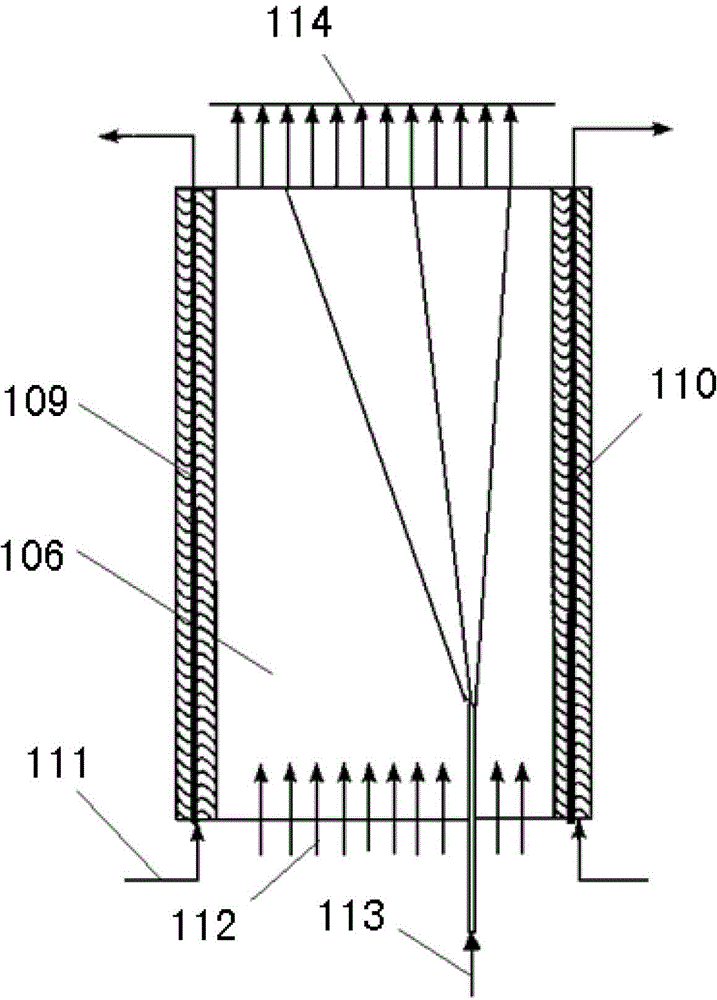

[0031] Such as figure 1 As shown, the separation device 100 of the present invention is similar to the prior art, including a cooling unit 101 with a metal shell, a separation chamber substrate 102 is arranged on the upper surface of the cooling unit 101, and a separation chamber substrate 102 is arranged on the upper surface of the separation chamber substrate 102. Conductive layer 103 and an insulating layer 104 . A separation chamber top plate 105 is disposed above the insulating layer 104 , and a separation chamber 106 is formed between the insulating layer 104 and the top plate 105 . An electrode chamber 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com