Method for improving silkworm chrysalis protein functional characteristics using ultrasonic wave coordinated with enzymolysis technology and product and application thereof

A technology of silkworm chrysalis protein and functional properties, which is applied in the fields of protein food processing, protein food ingredients, and applications, can solve the problems of low protein modification efficiency, and achieve the effects of widening uses, simple operation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

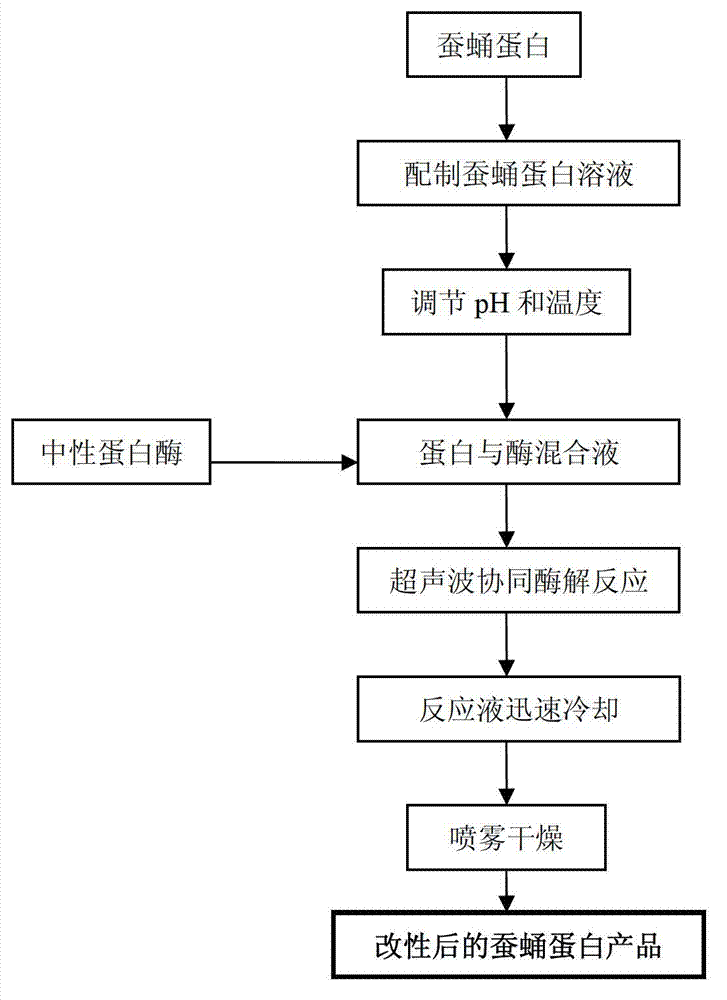

[0033] (1) Preparation of silkworm chrysalis protein solution

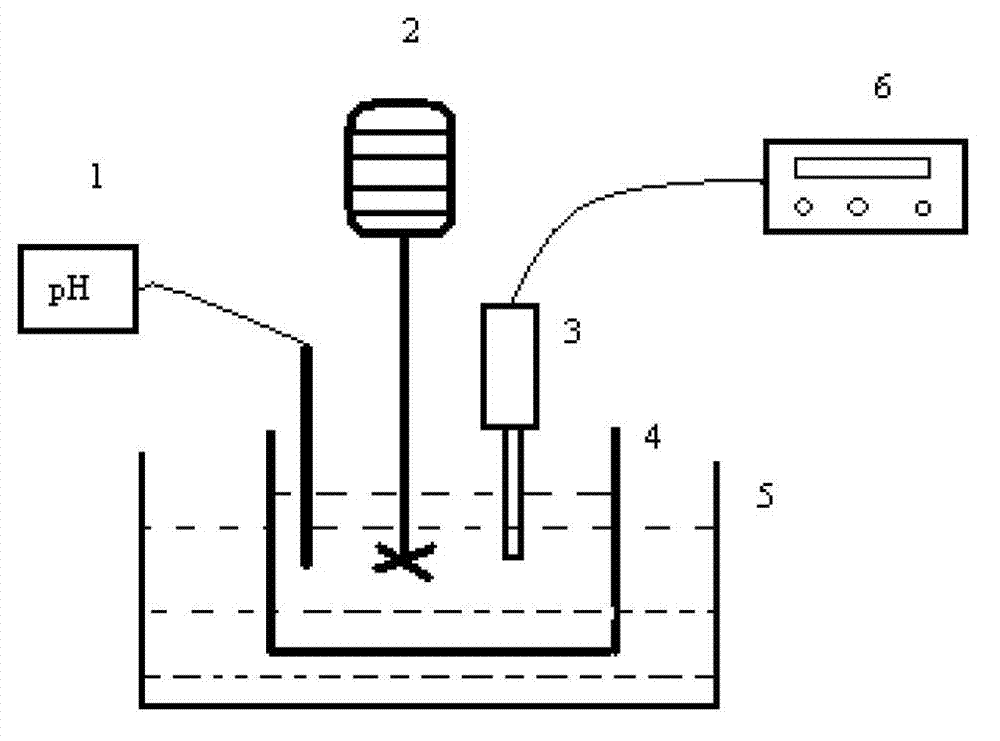

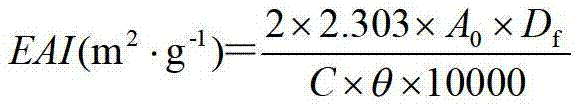

[0034] Prepare the silkworm chrysalis protein into a 1% (w / v) suspension with distilled water, adjust the pH to 6.0 after stirring evenly, and add it into the reaction tank together with neutral protease after heating to 40°C. The amount of neutral protease used is 2000U After stirring evenly, insert an ultrasonic probe to carry out ultrasonic synergistic enzymolysis reaction. The reaction conditions are: pH 6.0, temperature 40°C, ultrasonic power 0.5W / mL, continuous ultrasonic sound for 2s, intermittent 4s, ultrasonic synergistic enzymolysis The reaction time is 20 minutes; after the reaction is completed, the reaction mixture is rapidly cooled to about 4°C. Then use spray drying equipment to dry, the drying conditions are: the air inlet temperature is 190 °C and the air outlet temperature is 95 °C, and the powdery modified silkworm chrysalis protein product can be obtained. The functional characteristics of the ...

Embodiment 2

[0038] Prepare silkworm chrysalis protein into 5% (w / v) suspension with distilled water, adjust its pH to 6.5 after stirring evenly, and add it into the reaction tank together with neutral protease after heating to 45°C. The amount of neutral protease used is 3000U After stirring evenly, insert the ultrasonic probe to carry out the ultrasonic synergistic enzymolysis reaction. The reaction conditions are: pH 6.5, temperature 45°C, ultrasonic power 0.8W / mL, ultrasonic sounding continuously for 2s, intermittent for 4s, ultrasonic synergistic enzymolysis The reaction time is 25 minutes; after the reaction is completed, the reaction mixture is rapidly cooled to about 4°C. Then use spray drying equipment to dry. The drying conditions are: the air inlet temperature is 200°C and the outlet air temperature is 100°C. The powdery modified silkworm chrysalis protein product can be obtained. The functional characteristics of the product are shown in Table 2. It can be seen from Table 2 tha...

Embodiment 3

[0042] Prepare the silkworm chrysalis protein into a 10% (w / v) suspension with distilled water, adjust the pH to 7.0 after stirring evenly, and add it into the reaction tank together with neutral protease after heating to 50°C. The amount of neutral protease used is 4000U / g, after stirring evenly, insert an ultrasonic probe to carry out ultrasonic synergistic enzymolysis reaction, the reaction conditions are: pH 7.0, temperature 50°C, ultrasonic power 1W / mL, ultrasonic continuous sounding 2s, intermittent 4s, ultrasonic synergistic enzymolysis reaction The time is 30 minutes; after the reaction is completed, the reaction mixture is rapidly cooled to about 4°C. Then use spray drying equipment to dry, the drying conditions are: the air inlet temperature is 210 °C and the air outlet temperature is 110 °C, and the powdery modified silkworm chrysalis protein product can be obtained. The functional characteristics of the product are shown in Table 3. It can be seen from Table 3 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| emulsifying | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com