Oil tank air tightness water testing device

An air tightness and fuel tank technology, which is applied in the liquid/vacuum degree measurement of liquid tightness and by measuring the acceleration and deceleration rate of the fluid, etc., can solve the problems of long consumption time, deformation and damage, and complex fixed structure of the fuel tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

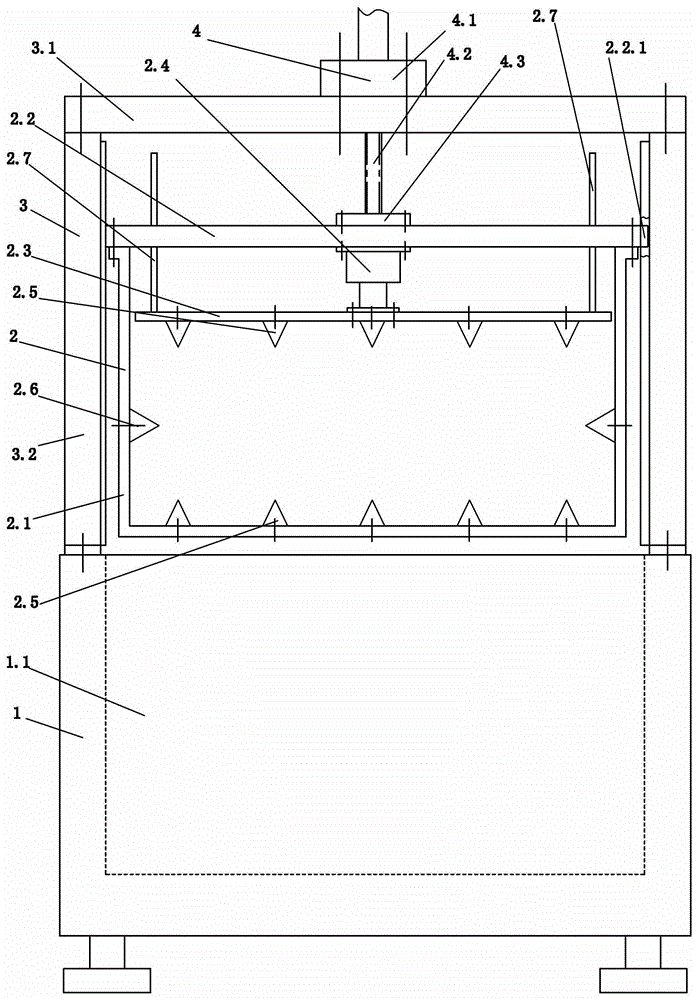

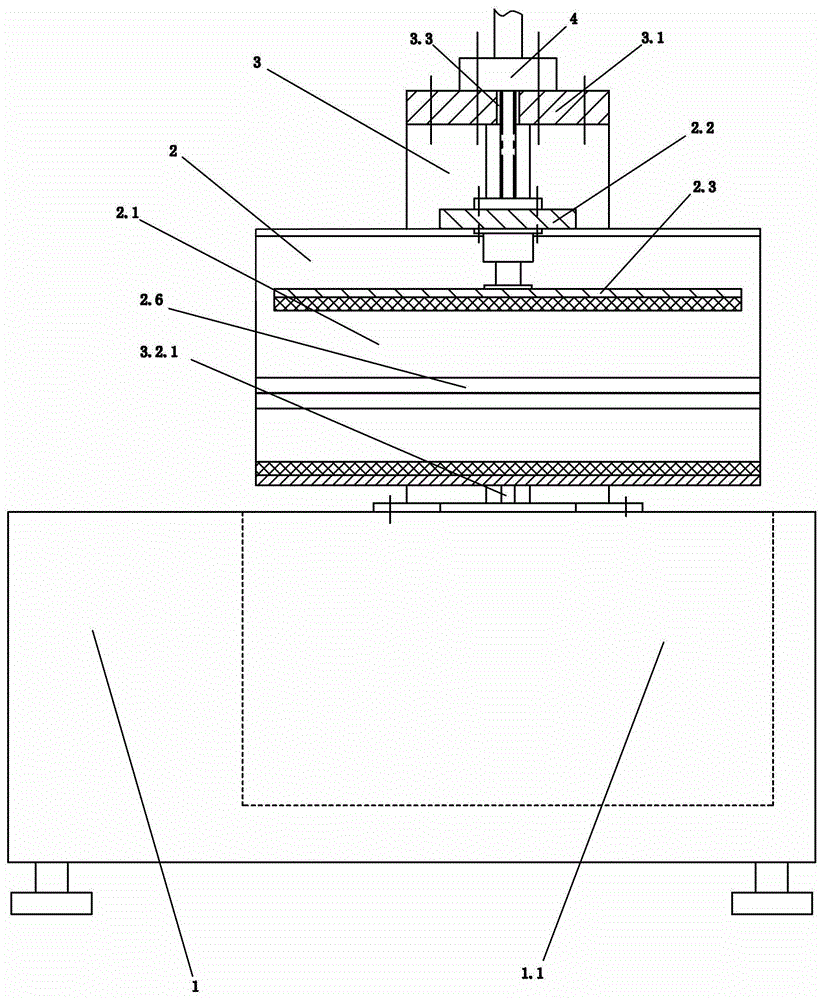

[0017] Such as figure 1 with figure 2 As shown, the present invention comprises the support 1 that is provided with detection pool 1.1 and detection control device, fuel tank fixing device 2, support 3 and lead screw elevator 4; The detection and control device for water change and the air pump, electromagnetic valve, sound alarm and other devices electrically connected to the detection and control device; the fuel tank fixing device 2 includes a U-shaped underframe 2.1, a moving beam 2.2, a fuel tank pressure plate 2.3 and a pressure plate cylinder 2.4 , the upper ends of the two side walls of the U-shaped underframe 2.1 are respectively fixedly connected with the two ends of the moving beam 2.2, the upper end of the cylinder block of the pressure plate cylinder 2.4 is fixedly connected with the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com