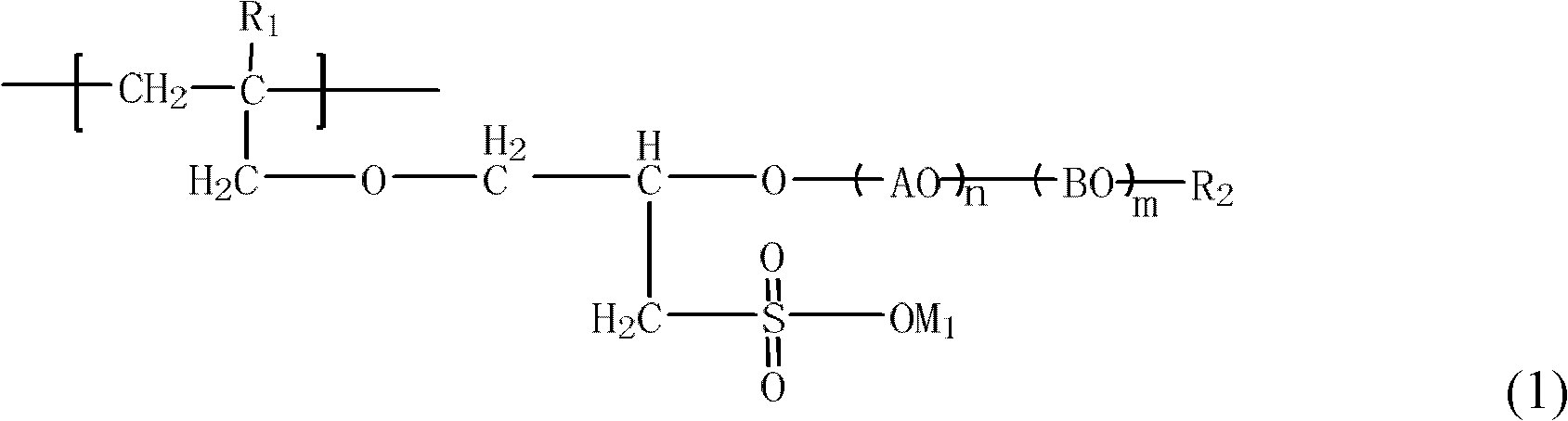

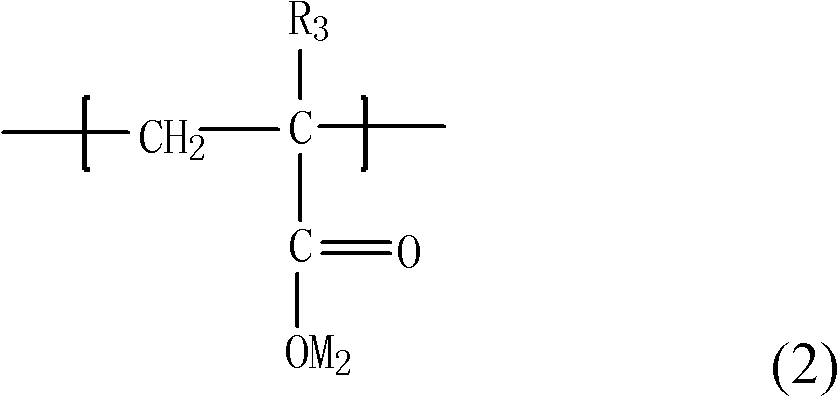

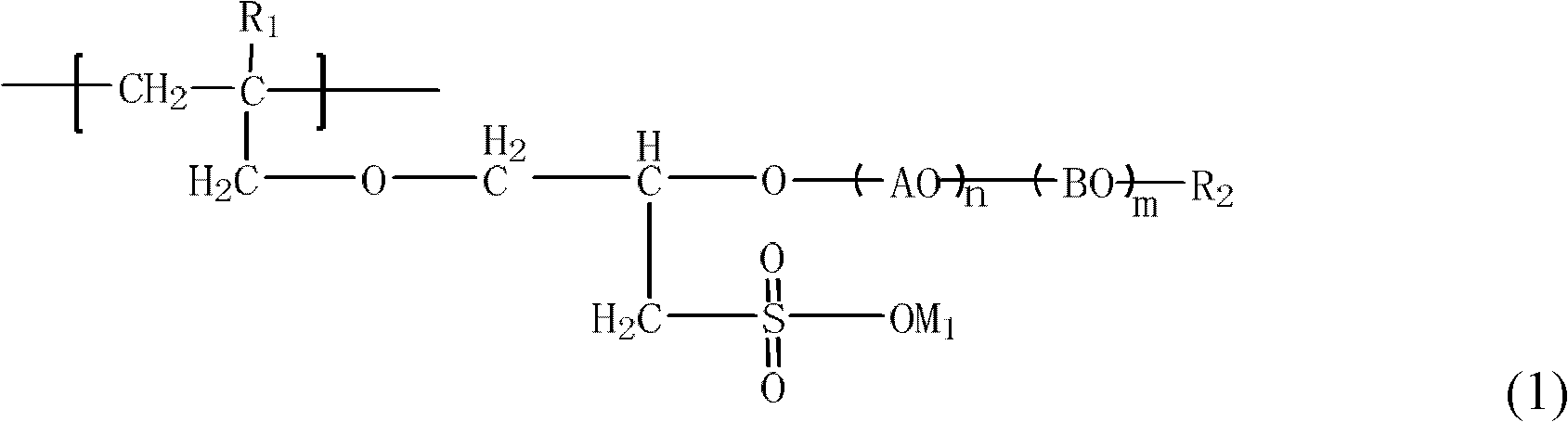

Allyl sulfonic glycerin polyoxyethylene polyoxypropylene ether polycarboxylic acid water reducer and its synthesis method

An allyl sulfonic acid-based glycerol and polymer technology, which is applied in the field of polymers and their synthesis, can solve problems such as unsatisfactory compounding methods, and achieve the effects of strong functionality and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0054] Add 39.6 g of allyl sulfonic acid glycerol and 0.21 g of sodium hydroxide into the autoclave, perform nitrogen replacement three times, then heat up the autoclave and start stirring. When the temperature in the kettle reaches the initiation temperature, add 2g of ethylene oxide. After the temperature rises and the pressure drops, add 64g of ethylene oxide continuously and stably, control the reaction temperature at 120-140°C, and control the flow rate for 2 hours. . After the feeding is completed, the aging reaction is carried out for 30 to 50 minutes under constant temperature conditions. Until the pressure no longer drops, the reaction is completed, and the temperature is lowered. When the temperature in the reactor drops to 90°C, take out 70.4g of material, and then add 0.22g of sodium hydroxide to the remaining 35.2g of material in the reactor for nitrogen replacement. After three times, the temperature of the reactor was raised, and 74.8 g of ethylene oxide was co...

Synthetic example 2

[0056] 26.4 g of allyl sulfonic acid glycerol and 0.21 g of sodium hydroxide were added into the autoclave, and after nitrogen replacement three times, the temperature of the autoclave was raised and stirring was started. When the temperature in the kettle reaches the initiation temperature, add 2g of ethylene oxide. After the temperature rises and the pressure drops, add 77.2g of ethylene oxide continuously and stably, control the reaction temperature at 120-140°C, and control the flow rate for 2 hours Finish. After the feeding is completed, the aging reaction is carried out for 30 to 50 minutes under constant temperature conditions. Until the pressure no longer drops, the reaction is completed, and the temperature is lowered. When the temperature in the reactor drops to 90°C, take out 79g of material, and then add 0.22g of sodium hydroxide to the remaining 26.6g of material in the reactor, and replace it with nitrogen three times. Finally, the temperature of the reactor was...

Synthetic example 3

[0058] 26.4 g of allyl sulfonic acid glycerol and 0.21 g of sodium hydroxide were added into the autoclave, and after nitrogen replacement three times, the temperature of the autoclave was raised and stirring was started. When the temperature in the kettle reaches the initiation temperature, add 2g of ethylene oxide. After the temperature rises and the pressure drops, add 77.2g of ethylene oxide continuously and stably, control the reaction temperature at 120-140°C, and control the flow rate for 2 hours Finish. After the feeding is completed, the aging reaction is carried out for 30 to 50 minutes under constant temperature conditions. Until the pressure no longer drops, the reaction is completed, and the temperature is lowered. When the temperature in the reactor drops to 90°C, take out 79g of material, and then add 0.22g of sodium hydroxide to the remaining 26.6g of material in the reactor, and replace it with nitrogen three times. Finally, the temperature of the reactor was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com