Hollow recombined bamboo and manufacturing method thereof

A manufacturing method and technology of recombined bamboo, applied in the direction of hollow objects, other household appliances, household components, etc., can solve the problems of heavy weight, small bearing pressure, and increased cost of recombined bamboo, and achieve good economy, applicability, and durability. Strong impact performance and excellent shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] Step 1. Preparation of bamboo unit:

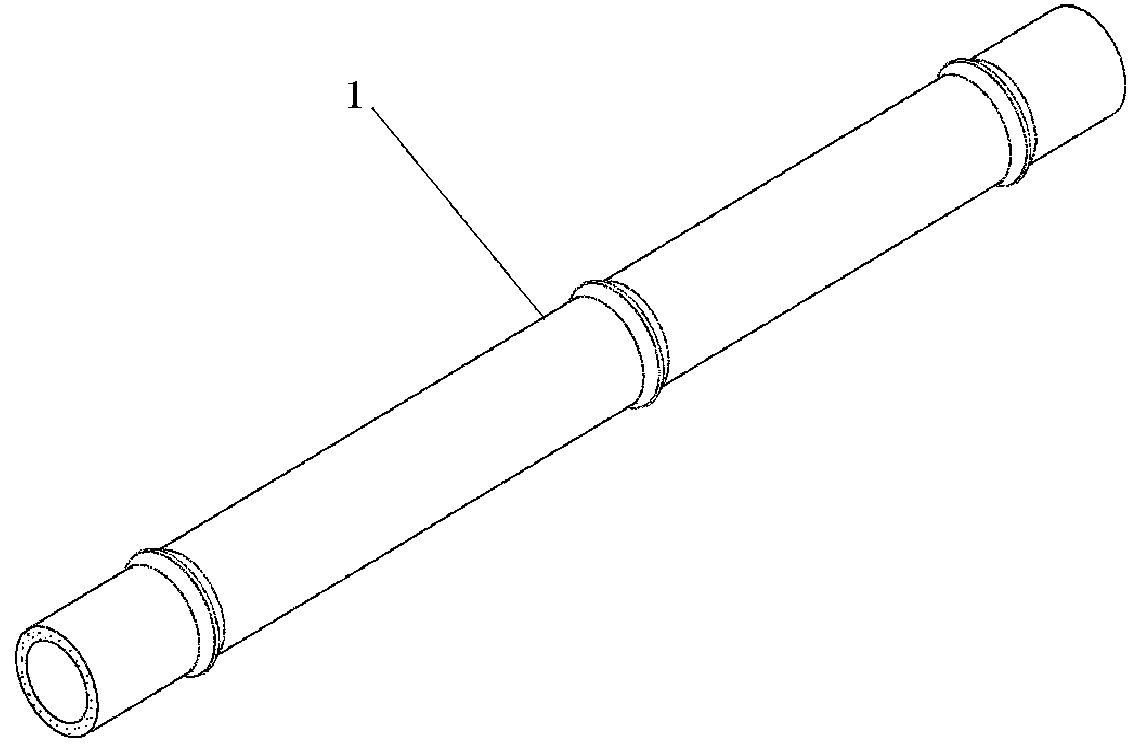

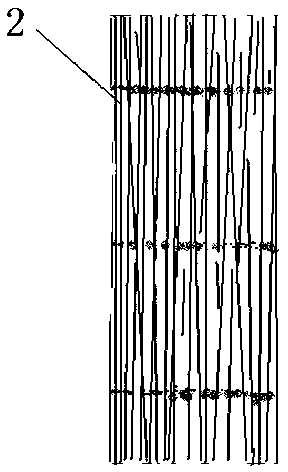

[0087] The original bamboo 1 with a bamboo age of 2 to 4 years is the best, after the section is determined (see figure 1 ), process the raw bamboo 1 into a mesh-shaped bamboo bundle of a certain specification through longitudinal loosening (see figure 2 ), or separated bamboo bundles 3 (see image 3 ), bamboo wire 4 (see Figure 4 ), bamboo strips 5 (see Figure 5 ). The netted bamboo bundles should be relatively scattered, that is, under the same height, the width of the netted bamboo bundles should be evenly distributed more than 2 times the width of the bamboo before separation, so that it is not easy to agglomerate, and if agglomerated, it will affect the formation of the subsequent sequence , the diameter of the reticulated bamboo bundle is 0.05-6mm; the separated bamboo bundle 3, or the single bamboo thread 4, has a diameter of 0.3-4mm, and a longitudinal length L≥0.5m; See Figure 5 ) or seamed bamboo strips, the size...

Embodiment 1

[0119] Specific steps include:

[0120] (1) Bamboo unit preparation

[0121] Raw bamboo 1 with a bamboo age of 2 to 4 years is selected, processed into bamboo segments, and processed into bamboo bundles 2 with a diameter of 1 mm and a length of 4 m through longitudinal loosening.

[0122] (2) heat treatment softening

[0123] The reticulated bamboo bundles are boiled in hot water at a temperature of 100° C. for 2 hours to enhance the plasticity of the reticulated bamboo bundles 2 and improve the anti-corrosion performance and stability.

[0124] (3) dry

[0125] Place the netted bamboo bundle 2 in a drying kiln, dry at 100°C, and control the moisture content at 8%

[0126] (4) dipping

[0127] Adhesive is phenolic resin, and the amount of dipping is 5% (the ratio of the dry weight of the resin to the dry weight of the bamboo unit); and dried or aged to a moisture content of 8%;

[0128] (5) Formation

[0129] In the molding groove 6 of the molding machine, the meshed bam...

Embodiment 2

[0139] (1) Bamboo unit preparation

[0140] Raw bamboo 1 with a bamboo age of 2 to 4 years was selected, processed into bamboo segments, and processed into bamboo bundles 2 with a diameter of 1.5 mm and a length of 5 m through longitudinal loosening.

[0141] (2) heat treatment softening

[0142] The reticular bamboo bundles are boiled in hot water at a temperature of 98° C. for 2 hours to enhance the plasticity, anti-corrosion performance and stability of the reticulated bamboo bundles 1 .

[0143] (3) dry

[0144] The netted bamboo bundles are placed in a drying kiln and dried at 100°C, and the moisture content is controlled at 8%.

[0145] (4) dipping

[0146] The adhesive is phenolic resin, and the dipping amount is 5% (the ratio of the absolute dry weight of the resin to the absolute dry weight of the bamboo unit); and dried or aged to a moisture content of 8%.

[0147] (5) Formation

[0148] The dried reticular bamboo bundles after sizing are placed in the embossing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com