Split-type automobile rear-axle housing assembly welding method

A car rear axle, split technology, applied in the direction of welding equipment, welding equipment, arc welding equipment, etc., can solve the problem of thickening the axle housing body feeding thickness, affecting the strength and stiffness of the axle housing, ellipticity and coaxiality deviation, etc. problems, to achieve the effect of saving equipment procurement funds, shortening the production cycle, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

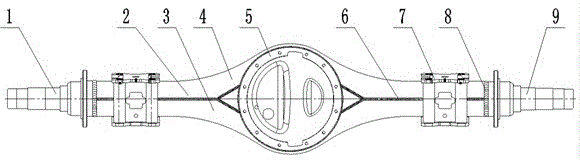

[0043] as attached Figures 1 to 2 As shown, the split type automobile rear axle housing welding method of the present invention specifically comprises the following steps:

[0044] ①. Production of the half-axle housing: select 16Mn steel plate with a thickness of 6mm, and carry out lofting according to the size requirements of the drawing. The blank is positioned and placed in the special mold of the hydraulic press, and the symmetrical upper half-shell 4 and lower half-shell 3 are made by pressing the hydraulic press. After pressing, the ellipticity of the semi-circular tubes at the ports on both sides is mainly controlled to be no more than 2mm;

[0045] ②. Half-shaft casing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com