Electron beam control system and method for electronic gun

A technology of electron beam current and control method, which is applied in the direction of circuits, discharge tubes, electrical components, etc., to achieve the effects of suppressing discharge, reducing electron beam current, and suppressing ripples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

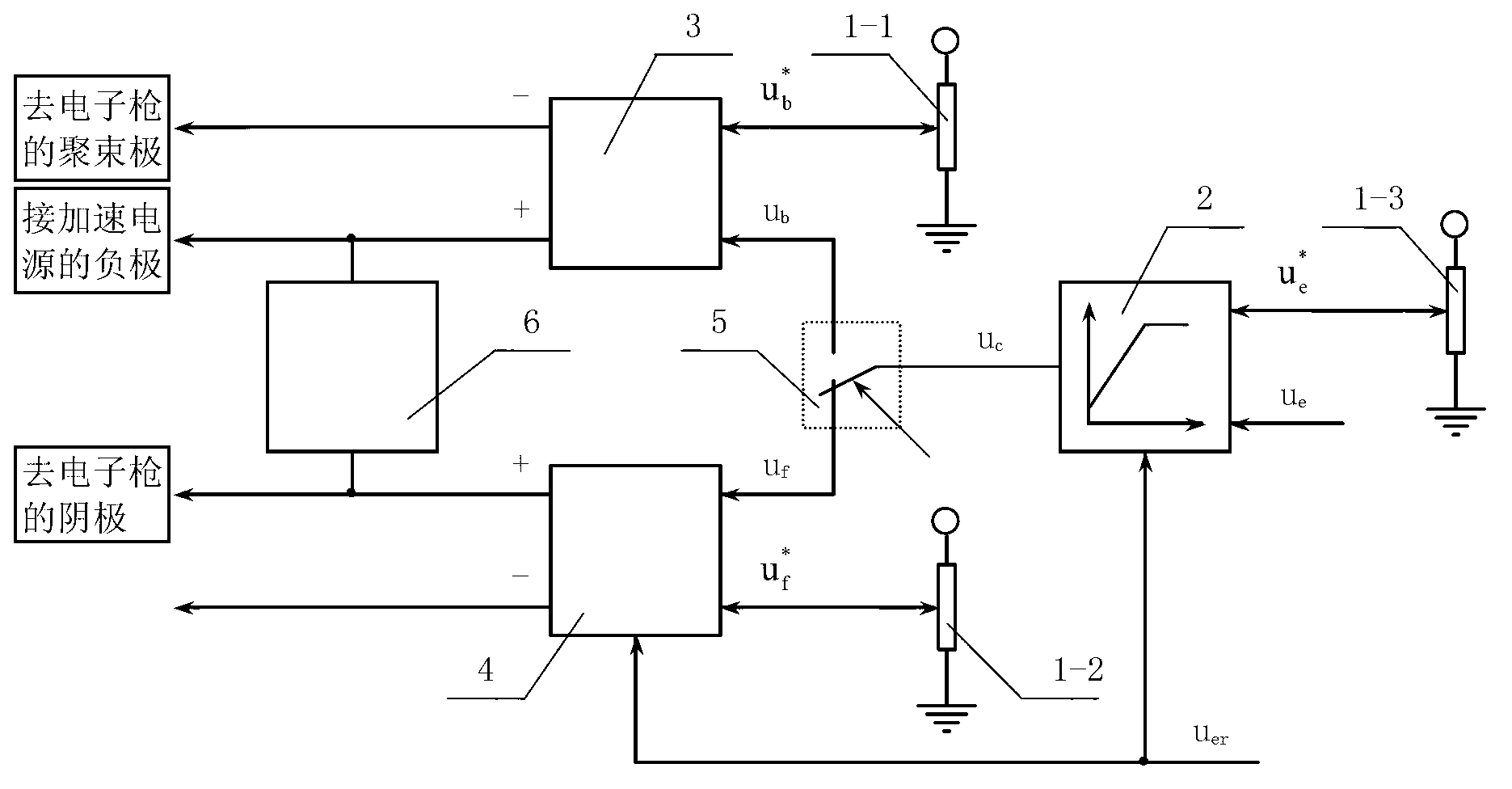

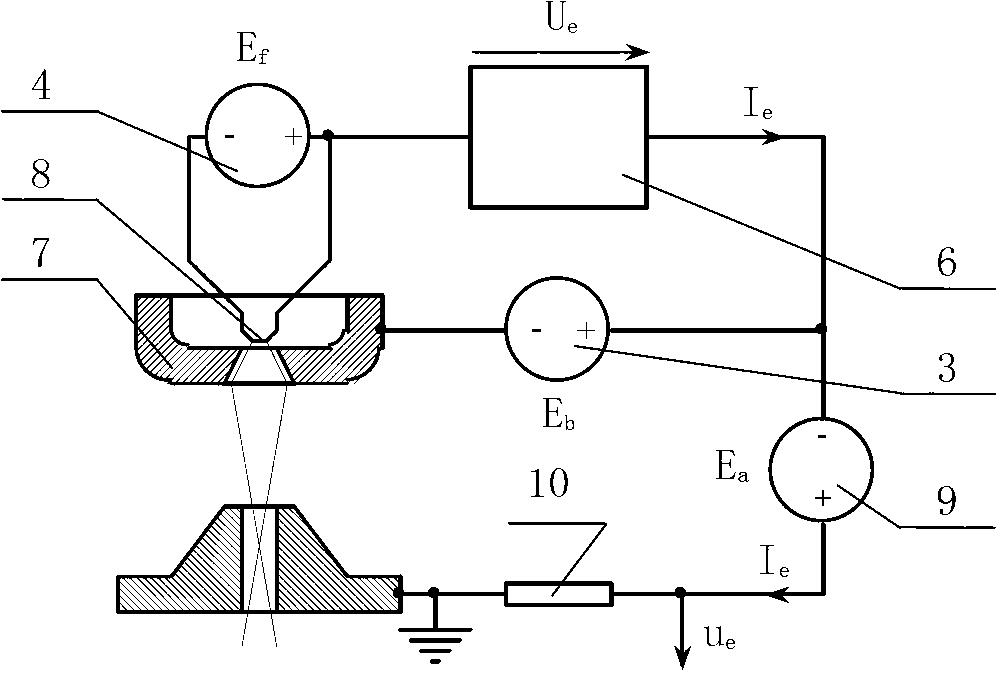

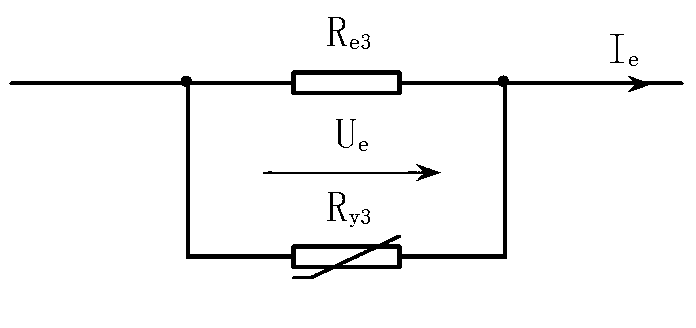

[0024] An electron beam current control system for an electron gun is mainly composed of a grid bias power supply unit 3 , a cathode power supply unit 4 , an electron beam current regulator 2 , a signal gating switch 5 , a self-stabilizing current device 6 , and a central control unit 1 . figure 1 The principle schematic diagram of the principle schematic diagram of the electron beam current control system of the electron gun of the present invention is given. figure 2 A schematic diagram of the connection between the power supply of the electron beam generating system of the electron gun, the self-stabilizing device 6 and the electron gun is given.

[0025] The central control unit 1 includes a grid bias power supply unit setting signal generator 1-1, a cathode power supply unit setting signal generator 1-2, and an electron beam current setting signal generator 1-3. Among them, the grid bias power supply unit setting signal generator 1-1 generates the voltage preset signal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com