Synthetic jet radiator

A technology for synthesizing jets and radiators, applied in the direction of heat exchanger types, indirect heat exchangers, heat transfer modification, etc., can solve the problems of large volume and restricted products, and achieve low production cost, easy production, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

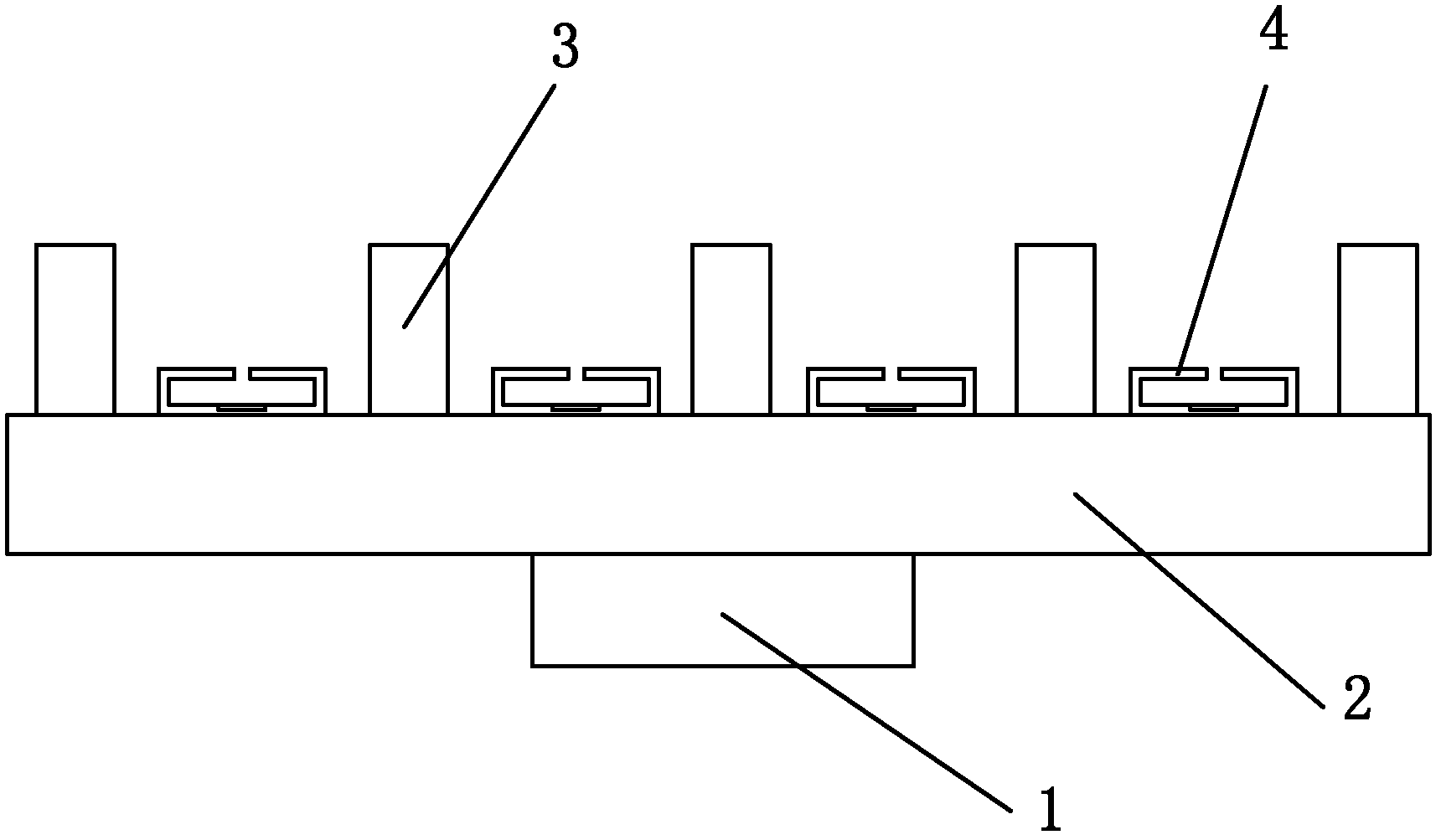

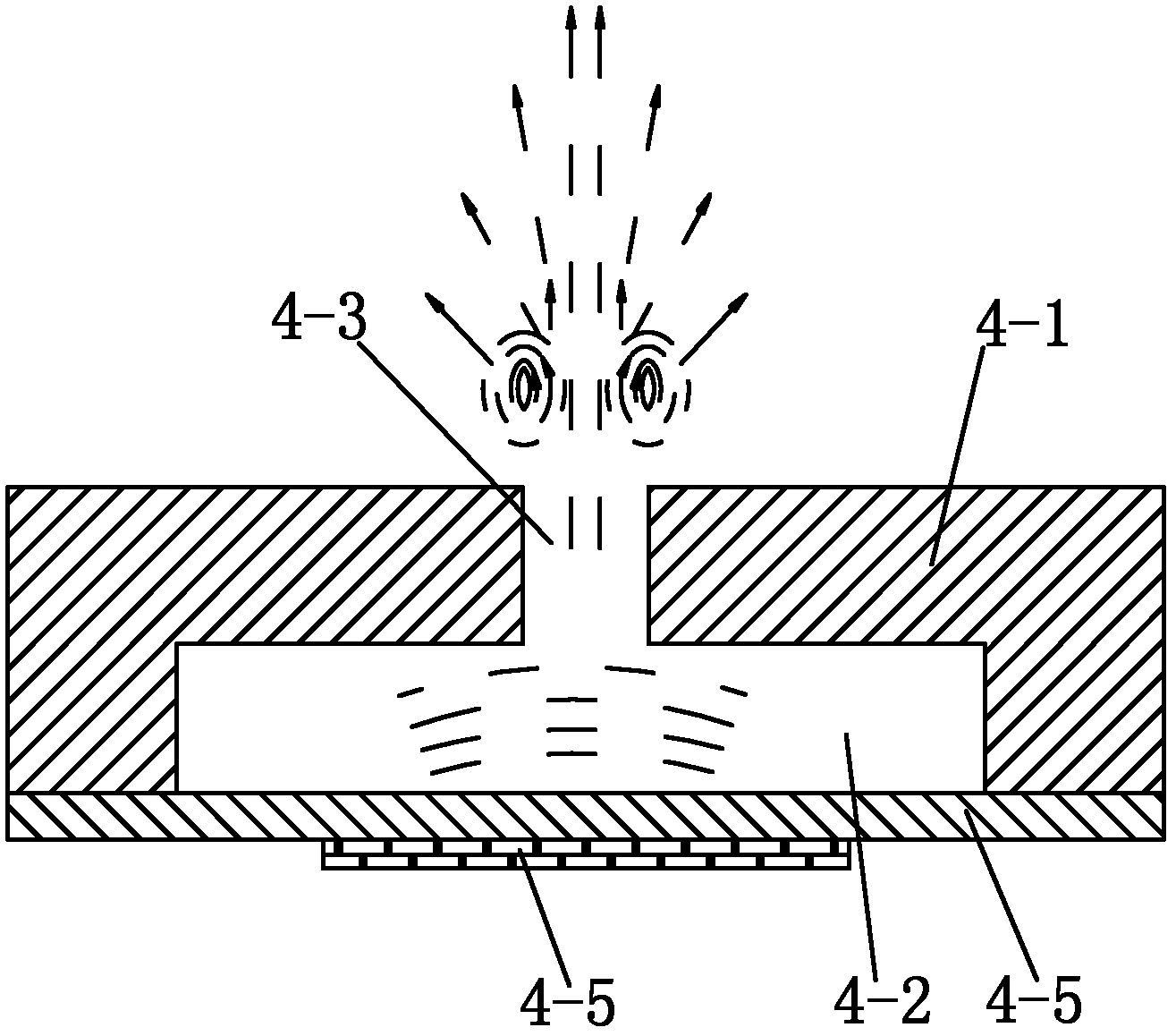

[0020] Such as figure 1 and figure 2 The synthetic jet radiator shown includes a heat source 1, and a heat sink 2 is arranged on the upper side of the heat source 1, and the cross section of the heat sink 2 is rectangular, hexagonal, elliptical or circular. A plurality of fins 3 are arranged on the upper side of the heat sink 2, and a plurality of synthetic jet devices 4 are arranged between the fins 3, and the synthetic jet device 4 is cylindrical. The synthetic jet device 4 includes a housing 4-1 with a cavity 4-2, the upper side of the housing 4-1 is provided with a nozzle 4-3, and the lower end of the housing 4-1 is provided with a vibrating diaphragm 4 -4, the lower side of the vibrating membrane 4-4 is provided with a piezoelectric film 4-5.

[0021] The working process of the synthetic jet radiator of the present invention is as follows: firstly, the synthetic jet radiator is installed at the working position, and when the heat source 1 generates heat, the heat gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com