Energy-saving emission-reducing partial oxygen-increasing combustion-supporting device used for cement kiln

A technology for energy saving and emission reduction, cement kiln, applied in the direction of indirect carbon dioxide emission reduction, combustion method, combustion equipment, etc., can solve the problems of not achieving the effect of energy saving and emission reduction, unable to adjust the angle, affecting the normal operation of the clinker rotary kiln, etc. Achieve significant comprehensive energy saving and emission reduction benefits, improve product quality and output, extend furnace life and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

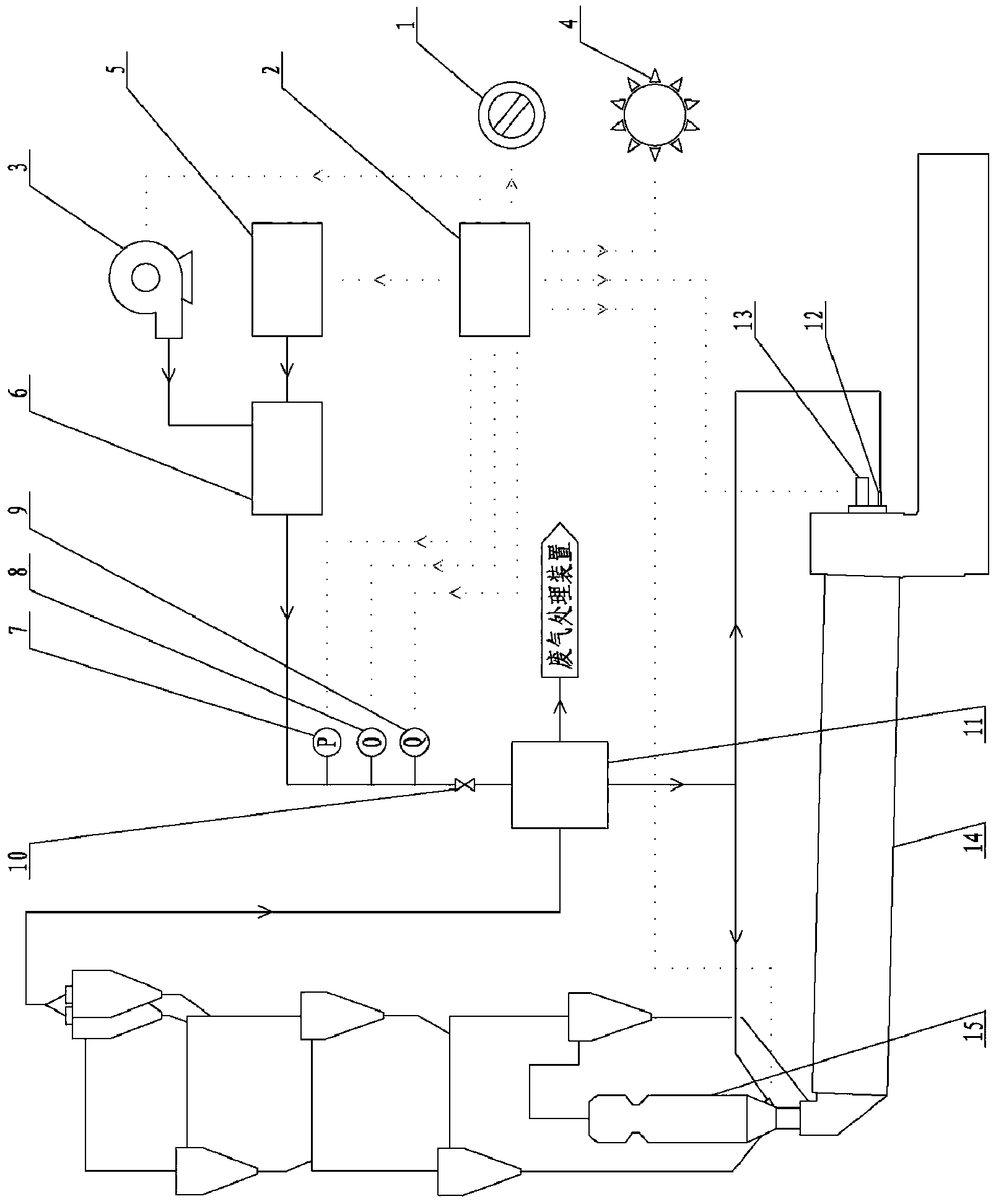

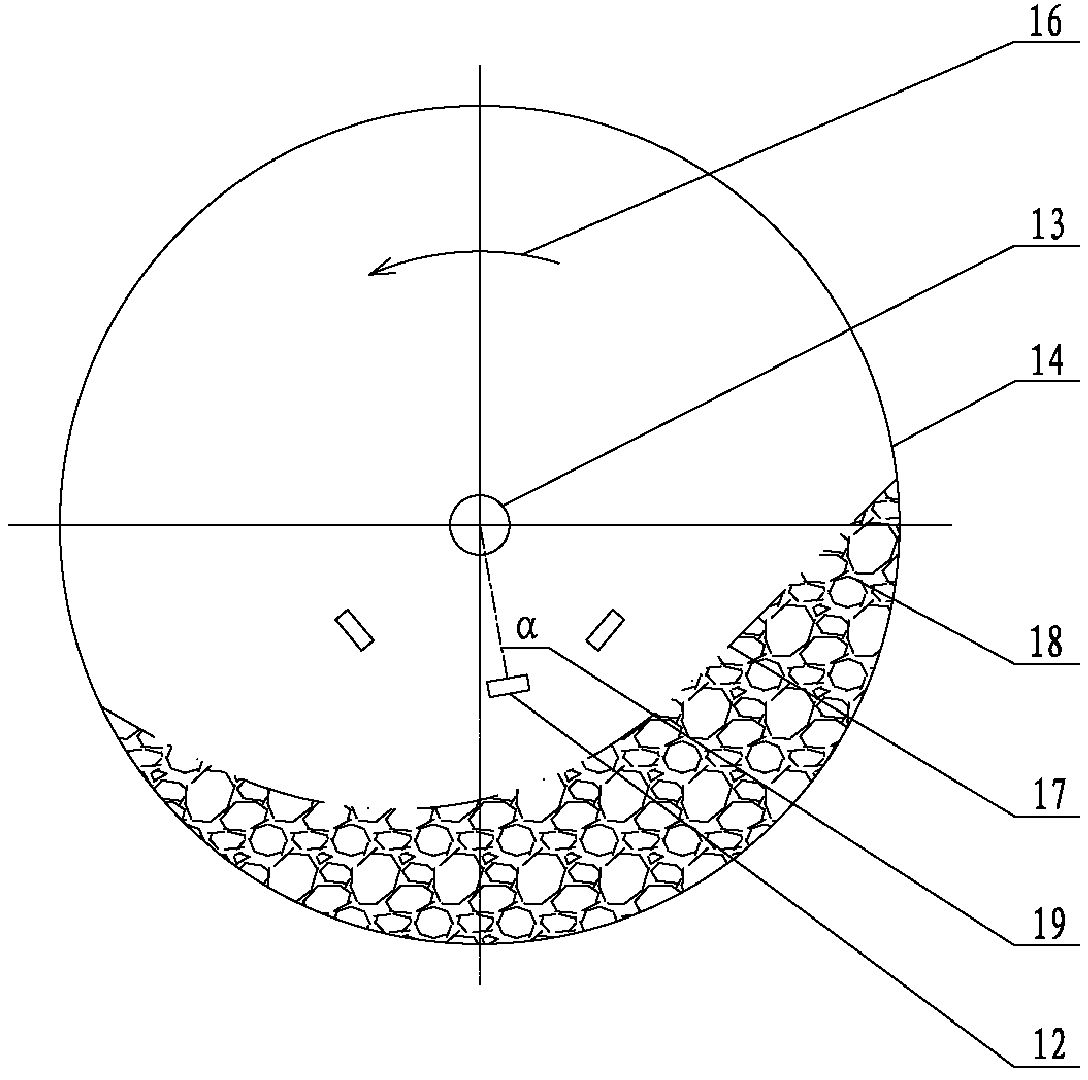

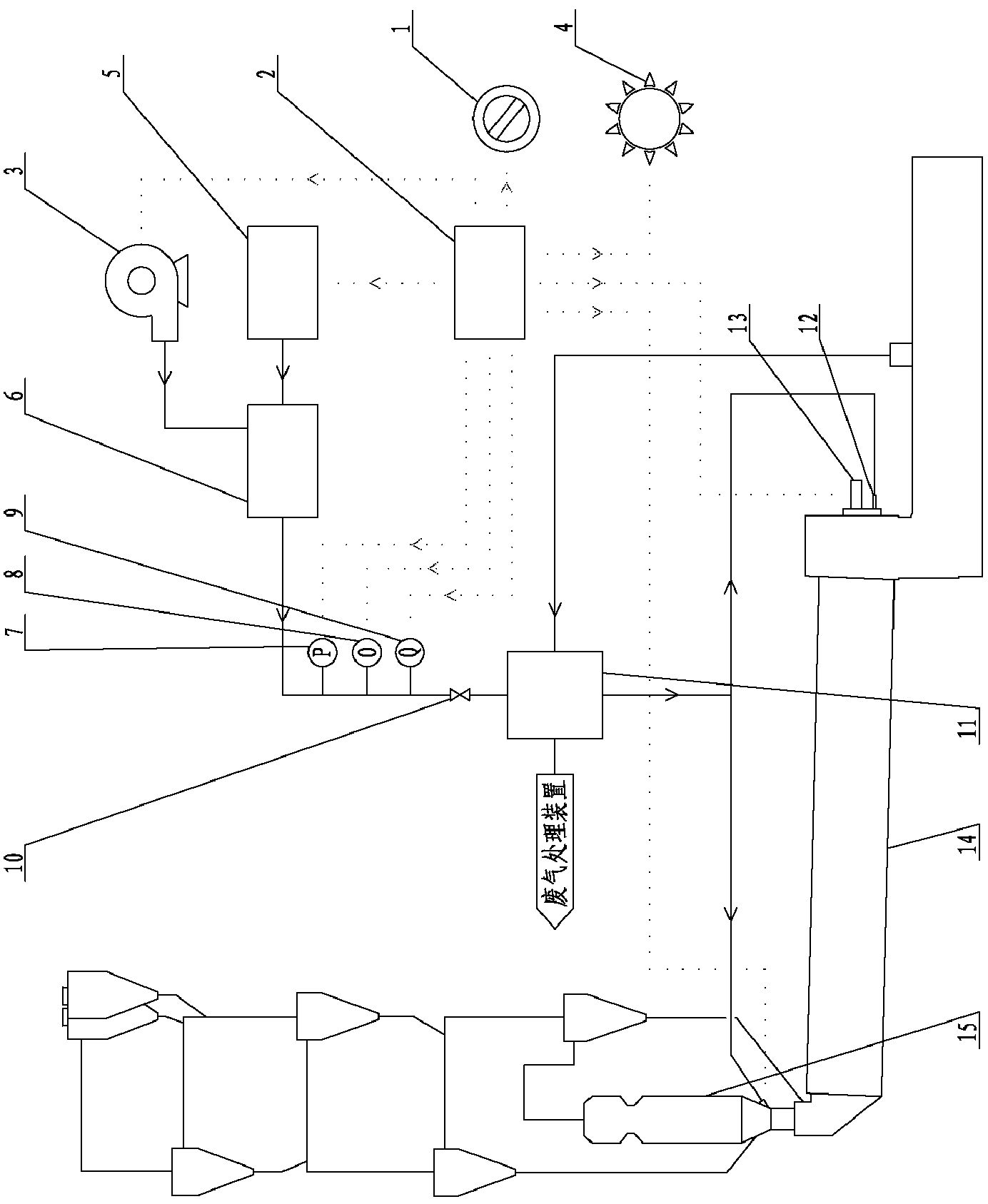

[0019] exist figure 1 In the schematic flow diagram of the partial oxygen-increasing and combustion-supporting device for energy saving and emission reduction in cement kilns shown, the outlet of the VPSA oxygen-enriched generator is connected to the oxygen-enriched inlet of the oxygen-enriched control device, and the air inlet of the oxygen-enriched control device is connected to the blower . An oxygen-enriched gas outlet is provided on the above-mentioned oxygen-enriched control device, which is connected with an oxygen-enriched preheater oxygen-enriched inlet through an oxygen delivery pipeline. An oxygen-enriched pressure transmitter, an oxygen-enriched concentration transmitter, an oxygen-enriched flow rate transmitter and a control valve are respectively arranged on the oxygen delivery pipeline. The flue gas inlet of the oxygen-enriched preheater is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com