Stoving neutralizing auxiliary reaction tower

A technology of reaction tower and sulfur fumigation, which is applied in the field of sulfur fumigation neutralization and auxiliary reaction tower, can solve the problems such as affecting the quality of sucrose and the recovery rate of cooking, uneven mixing of cane juice, unstable clarification reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

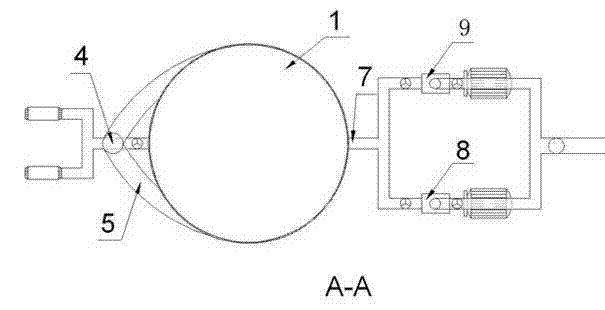

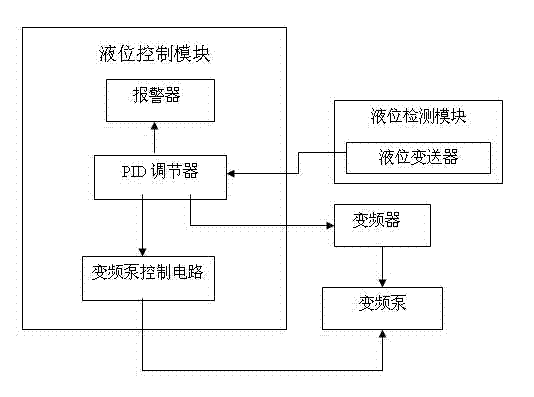

[0063] Such as Figure 1~Figure 3 As shown, the liquid level control device includes a liquid level detector, a liquid level control module and a frequency converter; the liquid level detector communicates with the tank body 1 through a pipeline to detect the liquid level in the tank body 1 , and transmit the liquid level information to the liquid level control module; the liquid level control module presets the limit value, and outputs the corresponding control signal to the frequency converter according to the difference between the received liquid level information and the limit value; the said The frequency converter controls the speed of the frequency conversion juice outlet pump 8 according to the control signal of the liquid level control module; the frequency conversion juice outlet pump 8 communicates with the tank body 1 through the juice outlet pipe 7;

[0064] The steps of the sulfur fumigation neutralization method carried out by using this equipment are as follow...

Embodiment 2

[0069] Such as Figure 1~Figure 4 As shown, the liquid level detector is a liquid level transmitter 6; the liquid level control module includes a PID regulator. The liquid level transmitter 6 detects the liquid level height information in the tank body 1, and converts the liquid level height information into an analog current signal and transmits it to the PID regulator; the PID regulator presets a limit value and will receive The received analog current signal is A / D converted into a liquid level digital signal, and the difference calculation is performed with the limit value, and then converted into a current signal by D / A and transmitted to the frequency converter; the frequency converter is based on the current output by the PID regulator The signal adjusts the frequency output to control the speed of the frequency conversion juice pump 8;

[0070] The steps of the sulfur fumigation neutralization method carried out by using this equipment are as follows:

[0071] a. Aft...

Embodiment 3

[0075] Such as Figure 1~Figure 4 As shown, on the basis of Embodiment 2, the liquid level control module is further optimized, and a variable frequency pump control circuit is added to the liquid level control module. The frequency conversion pump control circuit is used to control the frequency conversion juice pump 8 to be turned on or off. The method includes the following steps:

[0076] a. After sulfur fumigation and ashing, the cane juice enters the tank 1 through the sulfur fumigation neutralization reactor 2, and the liquid level rises continuously with the inflow of the cane juice, and the liquid level transmitter 6 detects the liquid in the tank 1 Level information, and convert the liquid level information into an analog current signal and transmit it to the PID regulator;

[0077] b. After the PID regulator receives the liquid level information, A / D converts the received analog current signal into a liquid level digital signal, performs difference calculation wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com