Quickly-demoulded weatherproof composition for polyurethane-reaction injection molding and preparation method thereof

A mold weather-resistant, injection molding technology, applied in the field of polyurethane, can solve the problem of poor light aging resistance of aromatic isocyanate, achieve the effect of high appearance gloss, superior light aging resistance, and shorten demoulding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

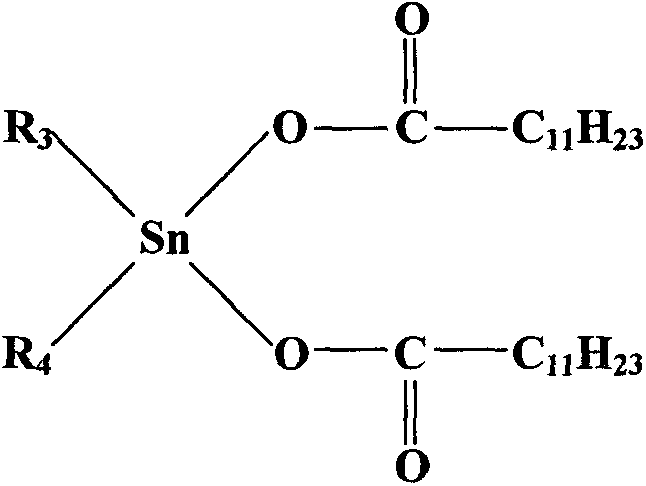

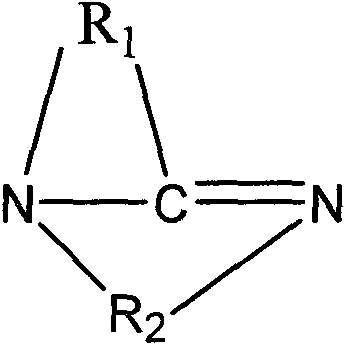

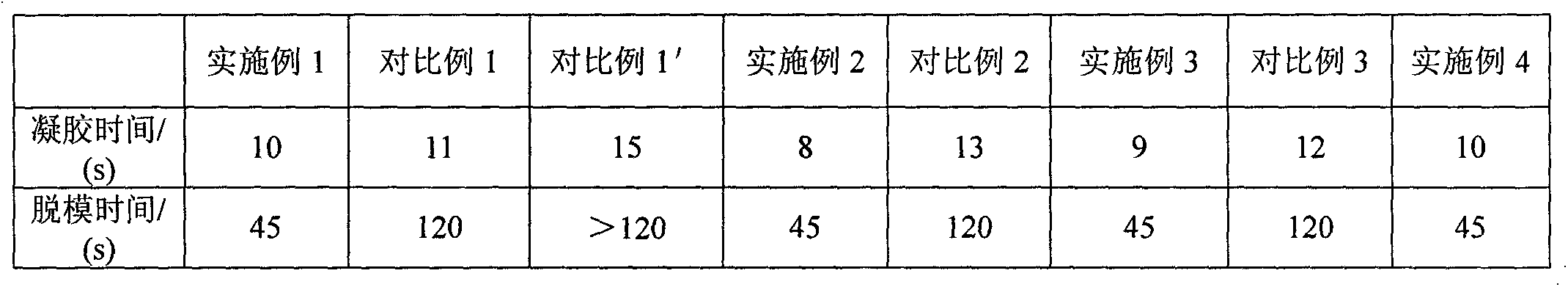

[0038] Examples Preparation of composite catalyst: Add 1 part of dibutyltin dilaurate, 5 parts of dimethyltin dilaurate and 2 parts of acetone into the container, stir and mix evenly at room temperature, then add 2 parts of bismuth octoate and stir Mix evenly, and then add 15 parts of 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole to obtain a composite catalyst.

[0039] Component B: isocyanate and modifier, heat up to 90°C with stirring, react for 3 hours, cool to room temperature and discharge.

[0040] The process of embodiment composition A, B component preparing PU-RIM material by RIM machine is as follows:

[0041] ①Feeding: According to the formula, pre-mix component A of the composition evenly and add it to the storage tank of component A of the high-pressure injection machine, and then weigh a certain amount of component B of the composition and add it to the storage tank of component B;

[0042] ②Injection: Set the material temperature of component A...

Embodiment 1

[0047] A component: 330N: 73 parts, ethylene glycol: 10 parts, trimethylolpropane: 10 parts, carbon black: 0.5 parts, 2-(2'-hydroxy-5'-methylphenyl)benzotri Azole: 0.6 parts; bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide: 0.4 parts; composite catalyst: 1.5 parts.

[0048] Component B: hydrogenated MDI: 80.1 parts, trimethylolpropane: 1.8 parts, polybutylene adipate (molecular weight: 3000): 18.1 parts. NCO mass fraction is 23.5%. Viscosity at 25°C is 800mPa.s.

Embodiment 2

[0056] A component: 330N: 71.2 parts, ethylene glycol: 18 parts, trimethylolpropane: 3 parts, carbon black: 2 parts, 2-(2'-hydroxy-3,5'-di-tert-butylphenyl )-5-chlorobenzotriazole: 2 parts; bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate: 1 part; composite catalyst: 2.8 parts .

[0057] Component B: hydrogenated MDI: 90.1 parts, trimethylolpropane: 2.4 parts, polytetrahydrofuran diol (molecular weight: 1000): 7.5 parts. NCO mass fraction is 26.0%. Viscosity at 25°C is 500mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com