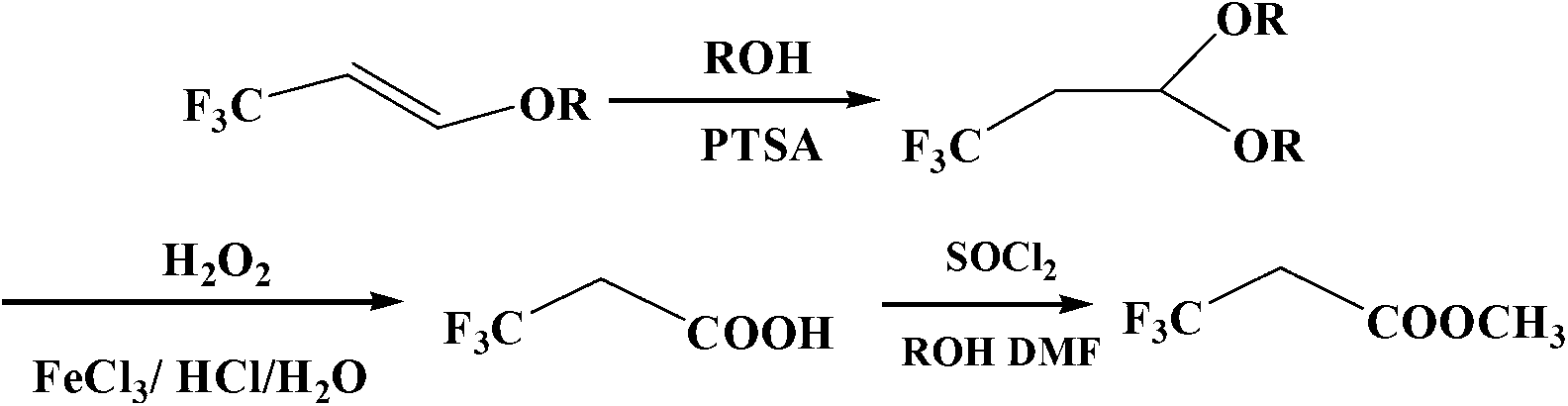

Preparation method of 3,3,3-trifluoromethyl propionate

A technology of methyl trifluoropropionate and trifluoropropionaldehyde dimethoxyethane, which is applied in the preparation field of the chemical technology field, can solve the problems of complicated post-processing, few reaction steps, low yield and the like, and achieves post-processing Simple, few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

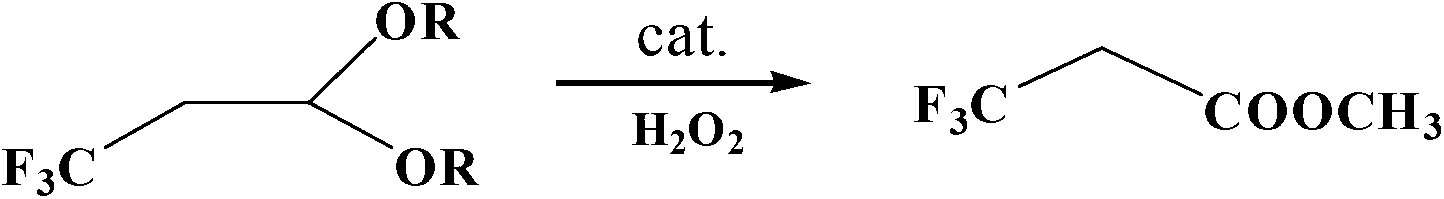

Method used

Image

Examples

Embodiment 1

[0016] At room temperature, 25 g of 3,3,3-trifluoropropionaldehyde dimethoxyethane, 2.0 g of hydrochloric acid (36% by mass fraction) and 1 g of V 2 o 5 Add it into the reaction bottle, heat up to 70°C, add 10g of hydrogen peroxide (mass fraction 30%) dropwise under stirring, then react at 70°C for 5 hours, cool, stand still, separate liquid, and collect at 70°C~73°C by atmospheric distillation Distillation obtained 16.8g of a colorless liquid with a purity of 98%, yield 75.0%.

Embodiment 2

[0018] Add 3,3,3-trifluoropropionaldehyde dimethoxyethane at room temperature: 25g, hydrochloric acid (mass fraction 36%): 2.5g, V 2 o 5 : 1.5g in a reaction flask, heated up to 70°C, added dropwise 13g of hydrogen peroxide (mass fraction 30%) under stirring, then reacted at 70°C for 5h, cooled, stood still, separated, and collected by atmospheric distillation at 70°C 17.1 g of a colorless liquid with a purity of 98% was obtained in a fraction at ~73°C, and the yield was 76.0%.

Embodiment 3

[0020] Add 25 g of 3,3,3-trifluoropropionaldehyde dimethoxyethane, 2.5 g of sulfuric acid and 1.2 g of CuCl at room temperature 2 In the reaction bottle, heat up to 70°C, add 12.5g of hydrogen peroxide (mass fraction 30%) dropwise under stirring, then react at 70°C for 5 hours, cool, stand still, separate liquid, and collect at 70°C~ At 73°C, 16.4 g of a colorless liquid with a purity of 98% was obtained, with a yield of 72.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com