Production process of high-purity isoolefine (tert-olefin)

A production process and isoolefin technology, which is applied in the field of high-purity isoolefin production process, can solve the problem of large loss of isoolefin products and achieve the effect of reducing emission losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

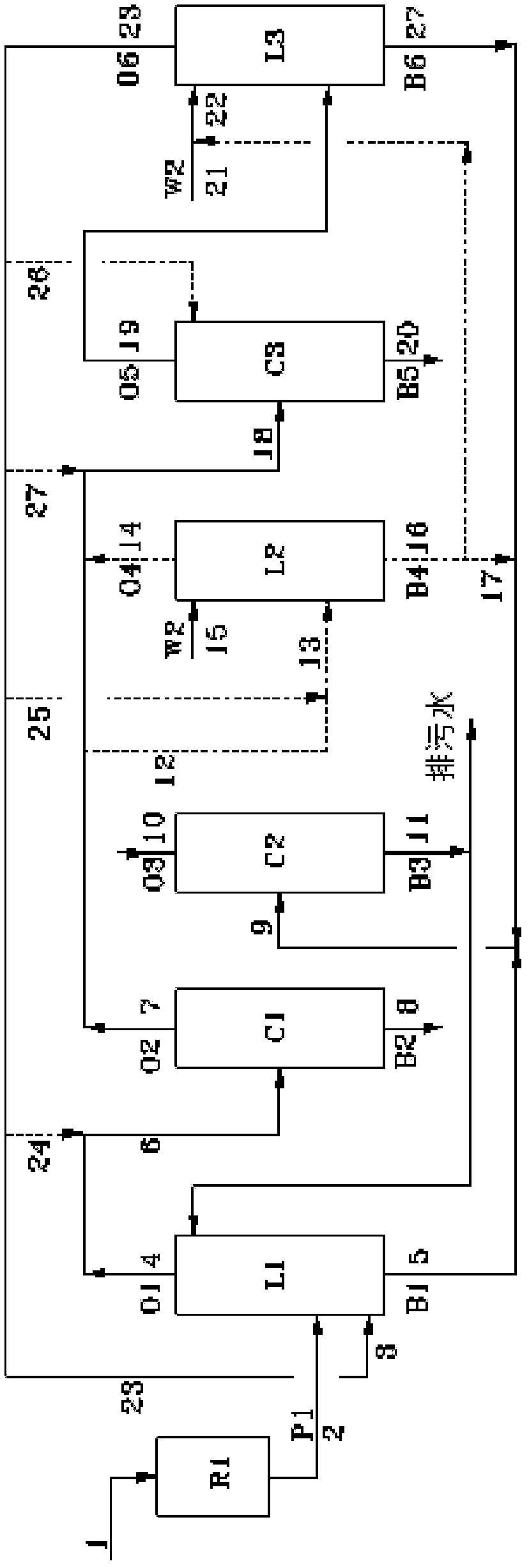

[0056] Process flow see attached image 3 , the hydrocarbon mixture containing methyl tert-butyl ether (from the methyl tert-butyl ether synthesis unit) enters the cracking reaction zone R1 through pipeline 1, wherein the content of methyl tert-butyl ether is about 98.5% (wt %) ( All the other compositions are shown in Table 1) The amount of raw material entering the cracking reaction zone R1 is 11000kg / h, the operating pressure of the reaction zone is 0.6MPa, and the operating temperature is 150°C. The reaction product P1 enters the water-washing separation tower L1 through the pipeline 2, and the operating pressure of the water-washing separation tower is 0.6MPa, the operating temperature is 40°C, the organic phase O1 mainly containing isoolefins, uncracked tertiary alkyl ether, and a small amount of low molecular weight ether is obtained at the top of the tower; the aqueous phase B1 mainly containing water and alcohol is obtained at the bottom of the tower.

[0057] Table 1...

Embodiment 2

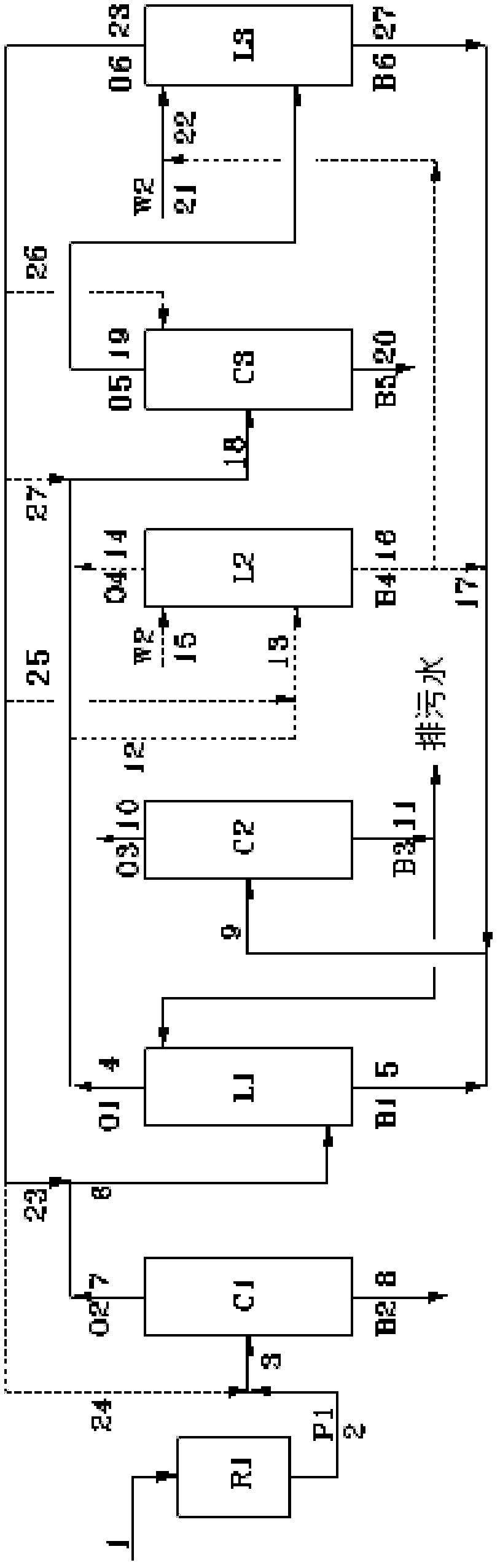

[0068] Process flow see attached Figure 4 The difference from Example 1 is that the organic phase O6 at the top of the water washing separation tower L3 enters the olefin fractionation tower C1 through pipelines 23 and 6, and the flow direction of the remaining materials and the operating parameters of each device are the same as in Example 1.

[0069] Provided in table 3 are the flow and composition data of the aqueous phase at the bottom of each water-washing separation tower, the organic phase at the top of the alcohol fractionation tower, and the organic phase at the bottom of the isoolefin refining tower in this process.

[0070] table 3

[0071]

Embodiment 3

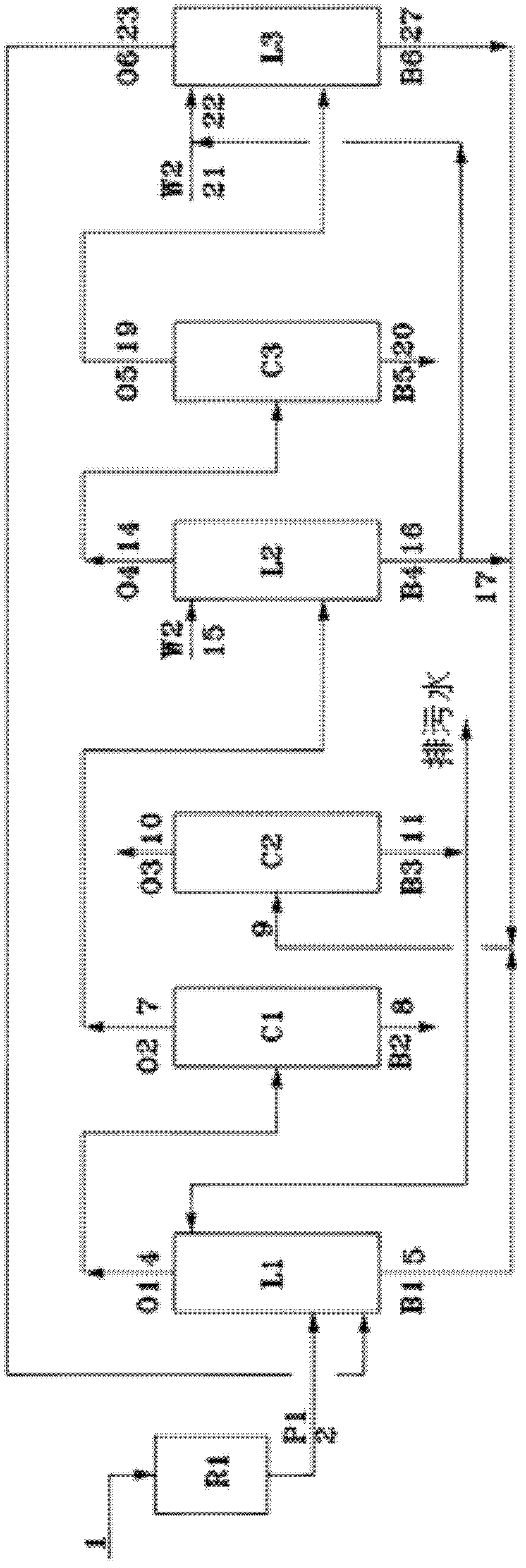

[0073] Process flow see attached Figure 5 , differs from Example 1 in that: the organic phase O6 at the top of the water-washing separation tower L3 enters the water-washing separation tower L2 through pipelines 23, 12, and the flow direction of all the other materials and the operating parameters of each device are all the same as in Example 1.

[0074]Table 4 shows the flow rate and composition data of the water phase at the bottom of each water washing separation tower, the organic phase at the top of the alcohol fractionation tower, and the organic phase at the bottom of the isoolefin refining tower in this process.

[0075] Table 4

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com