Method for advanced treatment and reuse of wastewater

A technology for advanced treatment and sewage, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of short service life, easy clogging of membrane modules, and low water production. Achieve the effect of highlighting technological progress, low operating cost, and high water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The technology of "biological aerated filter + ultrafiltration + electro-adsorption" is adopted, and the steps are as follows;

[0025] 1) Biochemical disposal of biological aerated filter

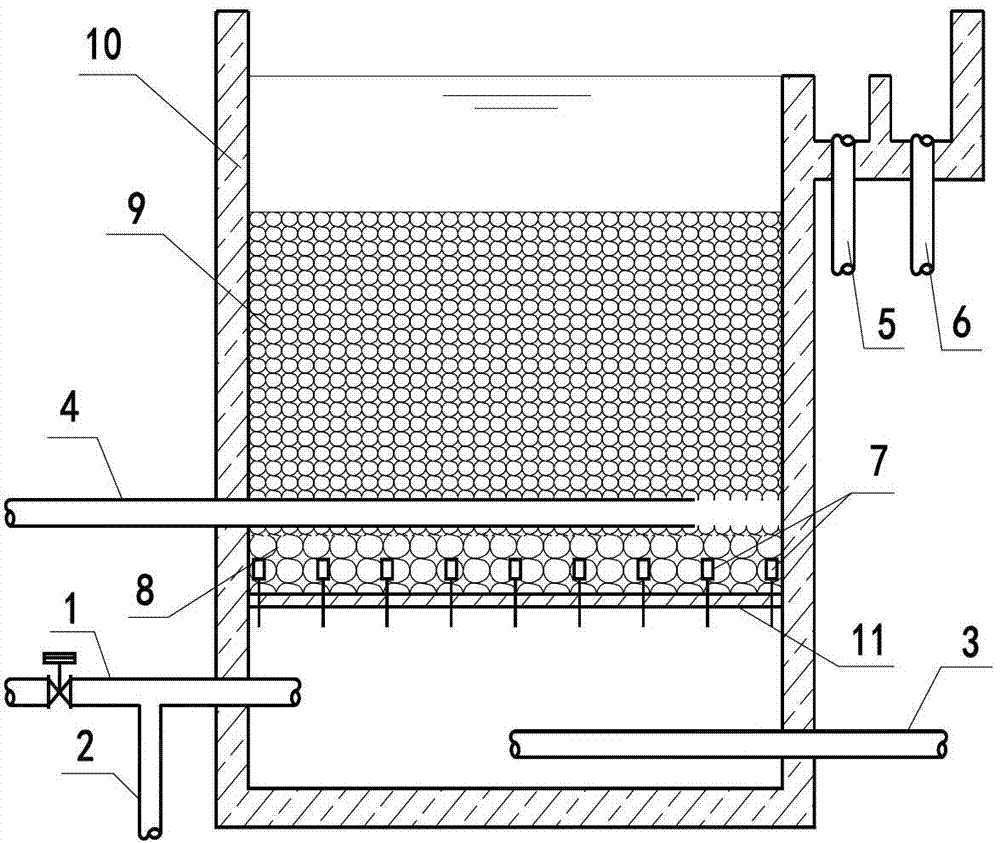

[0026] Its device structure: the filter plate 11 of the ceramic filter material 9 and the supporting packing 8 is arranged in the pool body 10 from top to bottom, and the filter plate 11 is evenly distributed with the water distributor 7; the ceramic filter material 9 and the supporting packing The aeration pipe 4 is arranged in the interlayer of 8; the backwash water inlet pipe 2 connected to the water inlet pipe 1 is arranged on the water inlet side of the lower part of the filter plate 11, and the backwash air inlet pipe 3 is installed on the other side; the ceramic filter material 9 is filled The upper layer, that is, the side of the water outlet on the pool body 10 is equipped with a backwash drain pipe 5 and a water outlet pipe 6;

[0027] During operation, open the pipe valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com