Photocatalytic composite gel bead and preparation method as well as application thereof

A composite gel and photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of titanium dioxide leakage and gel stability reduction. , to achieve the effect of short production cycle, rapid preparation, simple preparation process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A photocatalytic composite gel pellet according to the invention, the gel pellet uses alginate as a carrier, and titanium dioxide nanoparticles are loaded on the carrier. The photocatalytic composite gel beads are prepared by the following method:

[0025] 1.5 g of sodium alginate and 1.5 g of titanium dioxide were mixed with water to prepare 100 mL of a mixture. The mixture was added dropwise to 400 mL of 4% calcium chloride solution with a syringe to prepare pellets with uniform particles, reacted at room temperature for 4 hours, collected the pellets and washed several times to obtain a stable gel small ball. Then add the gel beads into 200 mL of an aqueous solution of 1% glutaraldehyde and 0.1 mol / L hydrochloric acid, stir and react at 40°C for 4 hours, collect and wash the gel beads The product was obtained after several times.

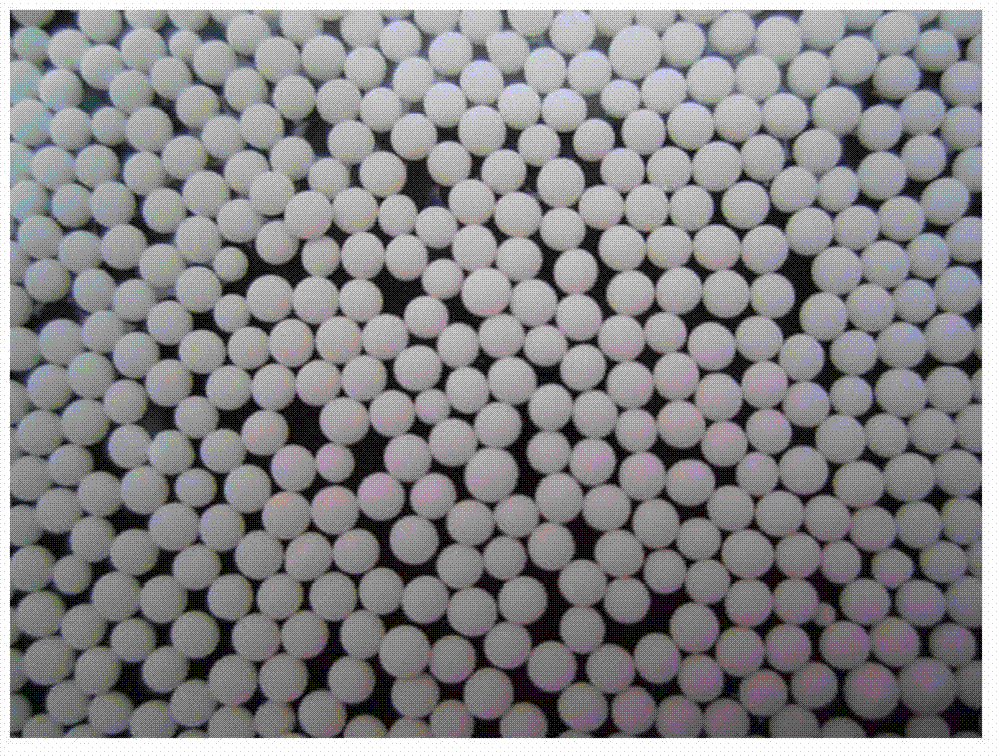

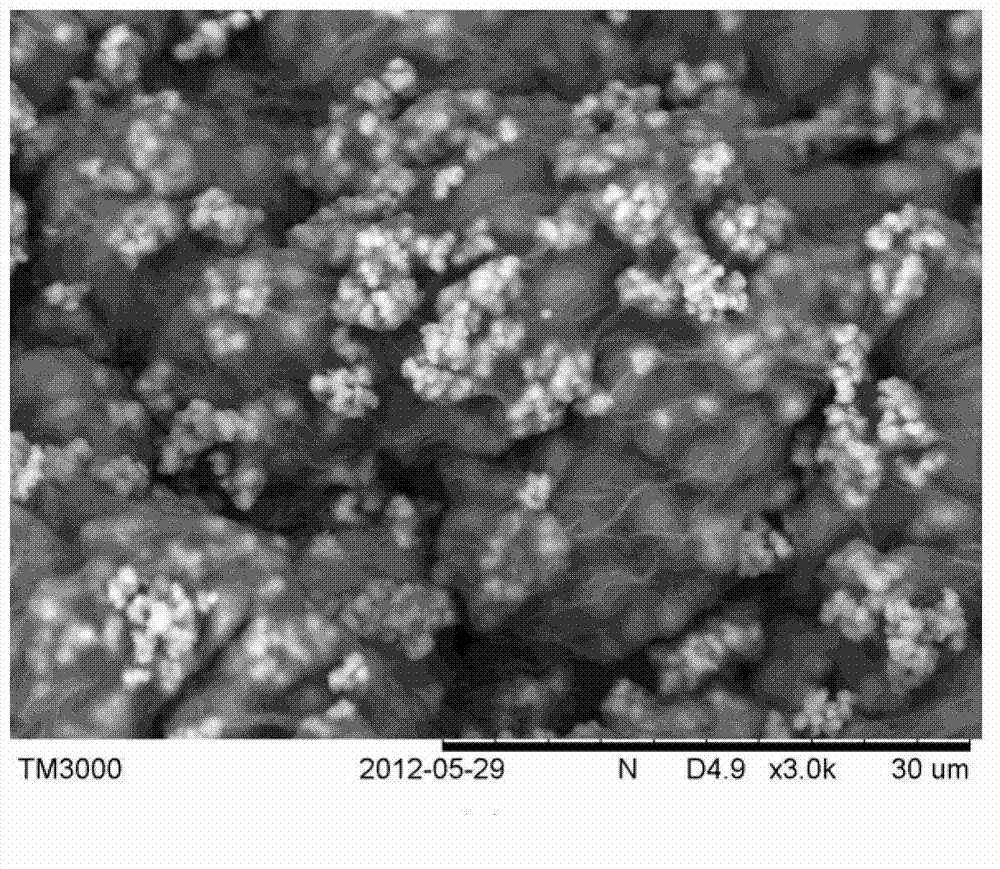

[0026] The digital photos of the photocatalytic composite gel beads made above are as follows: figure 1 As shown, its appearance is w...

Embodiment 2

[0028] The photocatalytic composite gel pellet of the present invention is used for photodegradation of hexavalent chromium ions in wastewater, comprising the following steps:

[0029] The photocatalytic composite gel beads prepared in Example 1 were added to 1 L of hexavalent chromium wastewater with an initial concentration of 10 mg / L. 10 g by weight, with HNO 3 or NaOH to adjust the pH value of the wastewater, and prepare five wastewater samples to be treated with a pH range of 2 to 6, insert an 8W UV lamp tube with a quartz glass shell in the middle of the reaction vessel, and place the reaction vessel in In an incubator at a temperature of 25°C, after 15 hours of magnetic stirring, the gel beads are separated from the wastewater, and the degradation treatment of hexavalent chromium ions in the wastewater is completed. Measure the amount of undegraded hexavalent chromium in the waste water with ultraviolet spectrophotometry, and the calculated removal rate results are sho...

Embodiment 3

[0034] The photocatalytic composite gel pellet of the present invention is used for photodegradation of hexavalent chromium ions in wastewater, comprising the following steps:

[0035] The photocatalytic composite gel beads prepared in Example 1 were added to the hexavalent chromium wastewater with a volume of 1 L and the initial pH value was 2. The initial concentrations of hexavalent chromium ions were 5, 10, and 20 mg / L, respectively. The amount added in 1 liter of waste water is 10 g based on the wet weight of photocatalytic composite gel beads. Insert an 8W ultraviolet lamp tube with a quartz glass shell in the middle of the reaction vessel, and place the reaction vessel at a temperature of 25°C for cultivation. In the box, after 15 hours of magnetic stirring, the gel beads are separated from the wastewater, and the degradation treatment of hexavalent chromium ions in the wastewater is completed. Measure the amount of undegraded hexavalent chromium in the waste water with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com