Group distribution streamline of lead storage battery plate wrapping machine

A lead-acid battery and assembly line technology, applied in the field of group distribution assembly line, can solve the problems of high harmful metals, low production efficiency, and worker contact, and achieve the effects of reducing hazards, ensuring accuracy, and reducing manual exposure to heavy metal lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

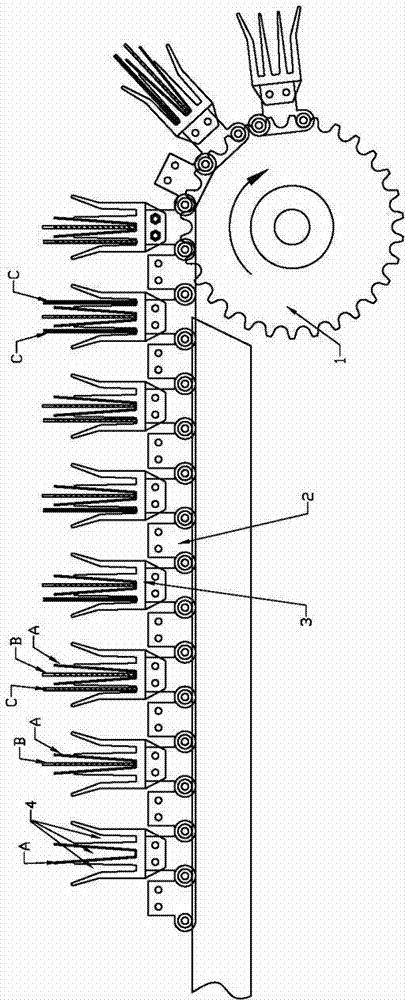

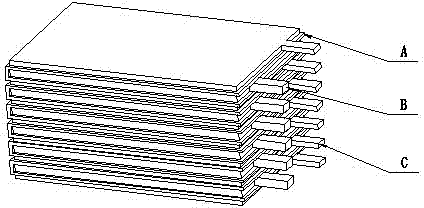

[0014] like figure 2 As shown, the lead storage battery group distribution line includes an endless chain 2 driven by a sprocket 1 and circularly moving. The endless chain has a section of horizontal conveying section for conveying group components; a plurality of Bracket 3 that can move synchronously with the chain. There are three slots 4 arranged in parallel on the bracket. Outside the horizontal conveying section, there is an inserting station for inserting separators, positive plates and negative plates into the slots. , so that the separator, positive plate or negative plate can be inserted by manual or automatic plate insertion mechanism; the end of the horizontal conveying section is provided with a take-out station for taking out the group components on the bracket, so that it can be taken out by manual or automatic take-out mechanism Sorted group widgets.

[0015] In the working process of the present invention, the sprocket 1 is driven by the servo motor, and driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com