Method for removing conductive layer of titanium fuel cell separator

A fuel cell and conductive layer technology, applied to fuel cells, cleaning methods using liquids, cleaning methods and appliances, etc., can solve the problems of reduced recycling efficiency and reduced yield, and achieve high yields and suppress losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

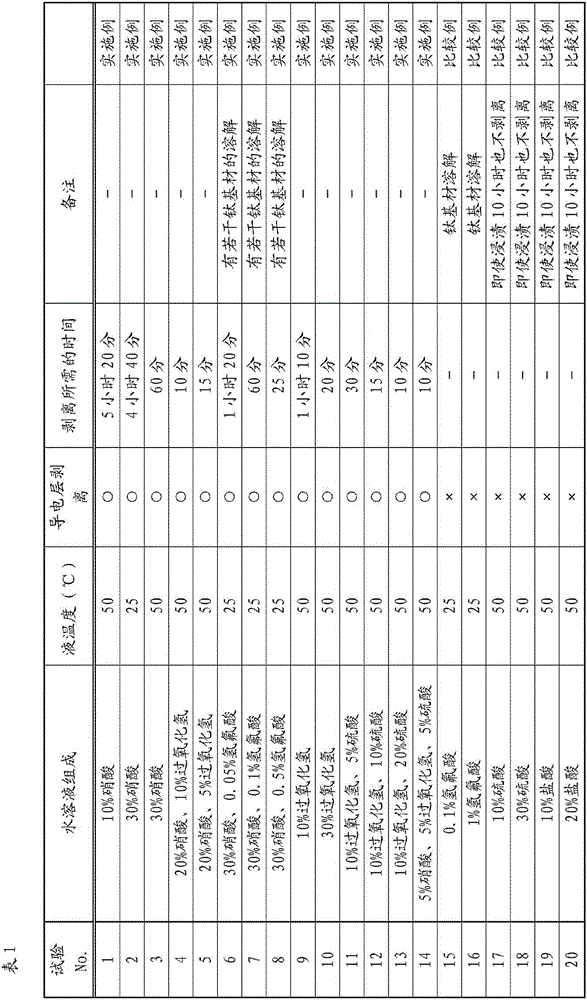

[0097] Next, with regard to the method for removing the conductive layer of the titanium fuel cell separator material of the present invention, Examples (Test Nos. 1 to 14) satisfying the requirements of the present invention and Comparative Examples (Test No. 15) not satisfying the requirements of the present invention are compared. ~20) to specify.

[0098] (Test material)

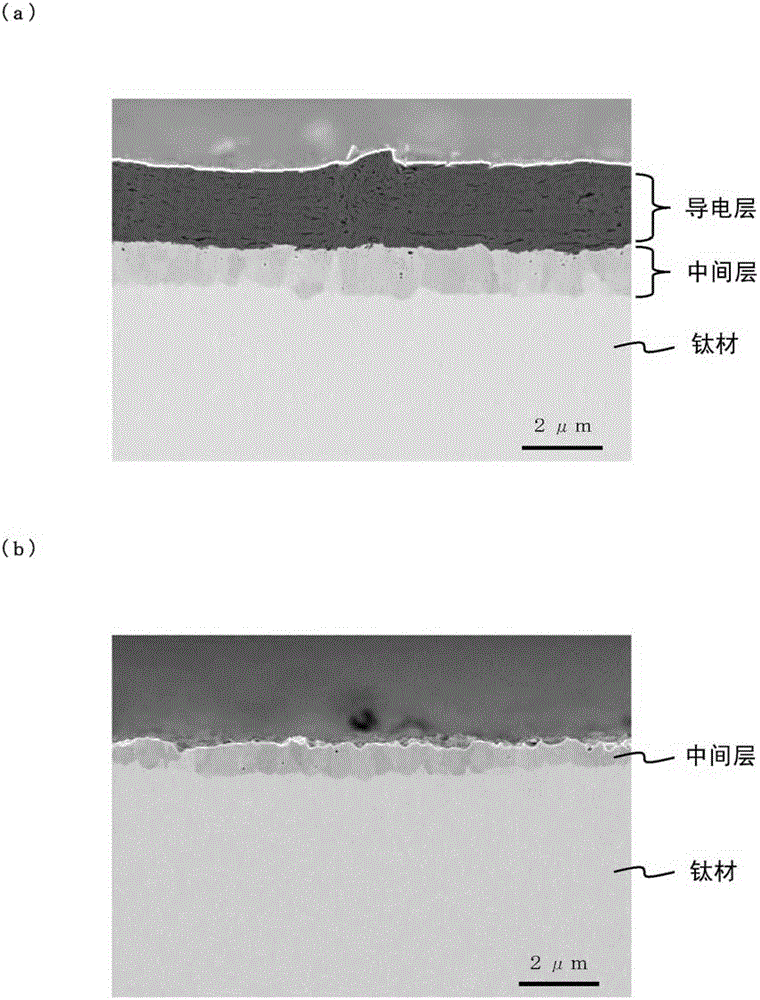

[0099] The base material is pure titanium material of JIS 1 type. After the slurry containing expanded graphite powder is coated on both sides of the base material, the two-stage roller punching machine is used for crimping, and then in a vacuum environment (6.7×10 -3 Pa) at 700°C for 60 minutes, and then heat-treated under furnace cooling conditions. The above-mentioned treatment was used to manufacture a test material in which a carbon-based conductive material was covered (on both sides) on a base material formed of pure titanium as a conductive layer, and a titanium carbide-containing material was f...

Embodiment 2

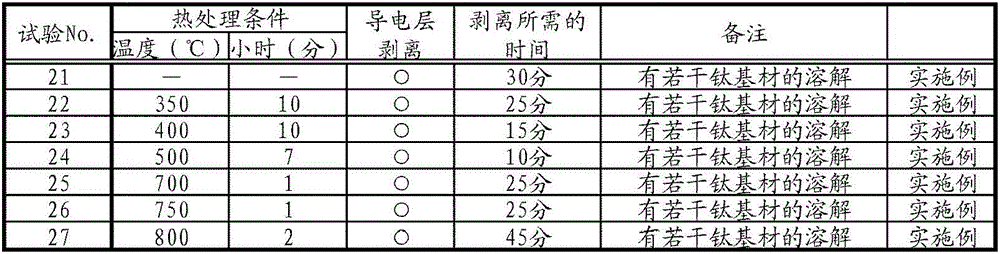

[0115] By the same process as in Example 1, a carbon-based conductive material covering (both sides) a base material made of pure titanium as a conductive layer was produced, and a middle layer containing titanium carbide was formed between the conductive layer and the base material. The material of the layer is cut and processed into a size of 20×30mm.

[0116] Then, a part was removed, and a heat treatment was performed at 350 to 750° C. for a predetermined time in an air atmosphere to prepare a test material.

[0117] (conductive layer removal test)

[0118] In the conductive layer removal test, 10 mass % nitric acid and 0.2 mass % hydrofluoric acid aqueous solution were used, 30 ml of the aqueous solution was put into a covered PP container (50 ml capacity), and the liquid temperature was adjusted to room temperature 50° C. for the test. In addition, the adjustment of the liquid temperature was performed using a constant temperature bath in the same manner as in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com