Mixing optics current transformer and method for achieving self-correcting measurement thereof

A current transformer and hybrid technology, applied in the field of sensors, can solve the problems of poor linearity, temperature drift of measurement accuracy, etc., and achieve the effect of eliminating influence, overcoming temperature drift, and eliminating changes in permeability and temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

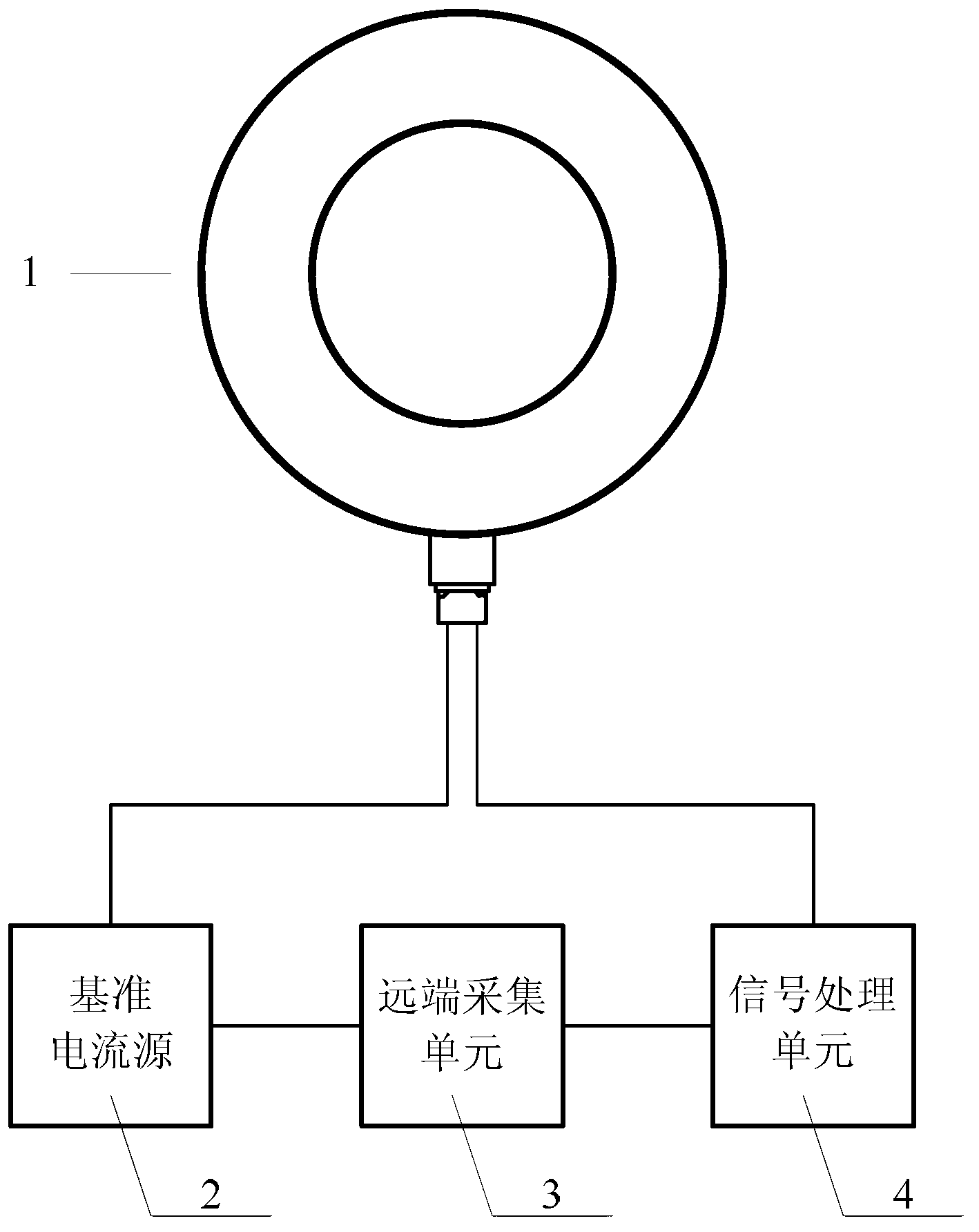

[0026] Specific implementation mode one: see figure 1 , figure 2 and image 3 Describe this embodiment mode, a kind of hybrid optical current transformer described in this embodiment mode, it comprises hybrid sensor head 1, reference current source 2, remote acquisition unit 3 and signal processing unit 4,

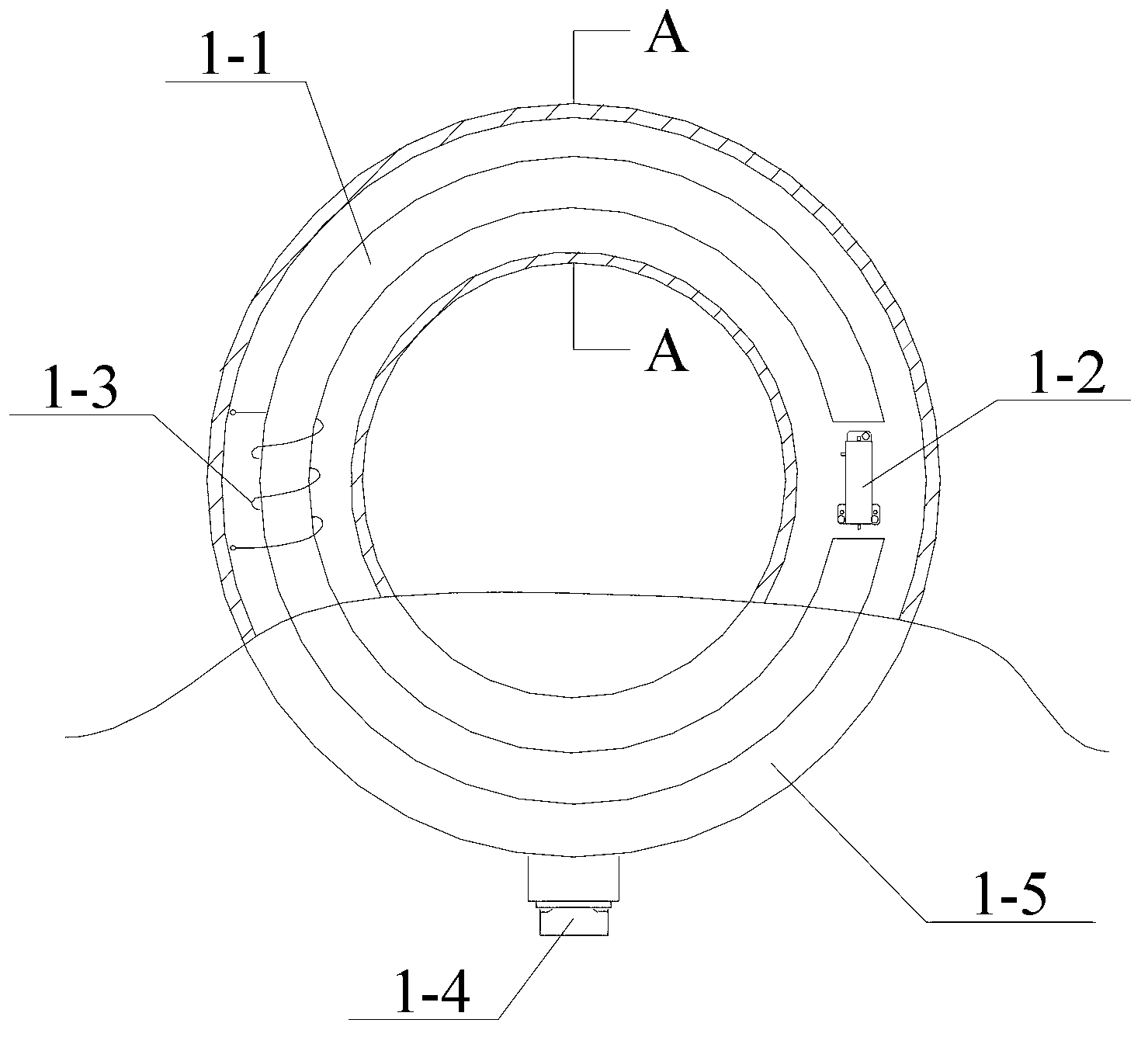

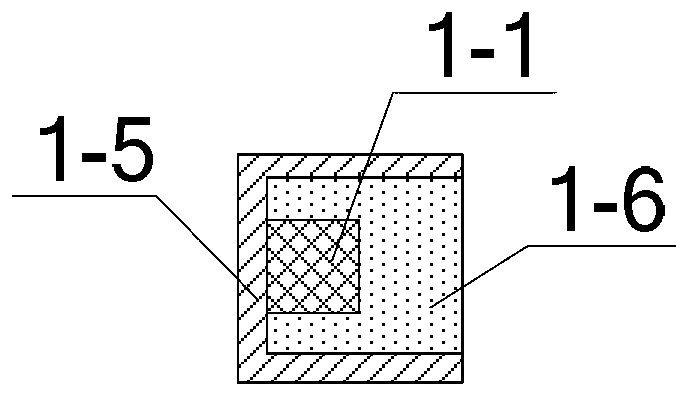

[0027] The hybrid sensor head 1 includes a magnetic collecting ring 1-1, an optical sensing unit 1-2, a self-calibration module 1-3, an aviation plug 1-4, a base 1-5 and an epoxy glue 1-6,

[0028] The base 1-5 is a circular base, and the base 1-5 is a U-shaped groove structure. The magnetic collecting ring 1-1, the optical sensing unit 1-2 and the self-calibration module 1-3 are installed on the base 1-5. 5, the magnetic collecting ring 1-1 is provided with an air gap, the optical sensing unit 1-2 is provided in the air gap, and the self-calibration module 1-3 is composed of a hollow solenoid. The hollow solenoid is sleeved on the magnetic collecting ring 1-1, and is ...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is a further limitation of the hybrid optical current transformer described in Embodiment 1. The optical signal output and input ends of the optical sensing unit 1-2 are optically connected to the signal processing unit 4 through an optical fiber. The signal output and input ends are connected, and the optical fiber is a multimode optical fiber.

specific Embodiment approach 3

[0033] Specific implementation mode three: see Figure 4This embodiment is described. This embodiment is a further limitation of the hybrid optical current transformer described in Embodiment 1. The optical sensing unit 1-2 includes a collimator 1-2-1, a polarizer Device 1-2-2, magneto-optic crystal 1-2-3, beam splitting prism 1-2-4, first coupler 1-2-5 and second coupler 1-2-6, optical sensing unit 1- The light input from the optical signal input end of 2 is incident to the collimator 1-2-1, and output to the polarizer 1-2-2 through the collimator 1-2-1, and then passed through the polarizer 1-2-2 After being transmitted, it is incident on the magneto-optic crystal 1-2-3, and after being transmitted by the magneto-optic crystal 1-2-3, it is incident on the beam splitting prism 1-2-4, and the transmitted light after being transmitted by the beam splitting prism 1-2-4 is incident on the first A coupler 1-2-5, the reflected light reflected by the beam-splitting surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com