Automatic exhaust valve of heating medium oil system

An automatic exhaust valve, medium oil technology, applied in valve details, valve devices, liquid degassing, etc., can solve the problem that the sealing material rubber of the automatic exhaust valve is not resistant to oil, cannot meet the operation of heat medium oil, and cannot achieve oil-gas separation and other problems, to reduce fire hazards, solve circulation pump evacuation and severe vibration faults, and improve pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

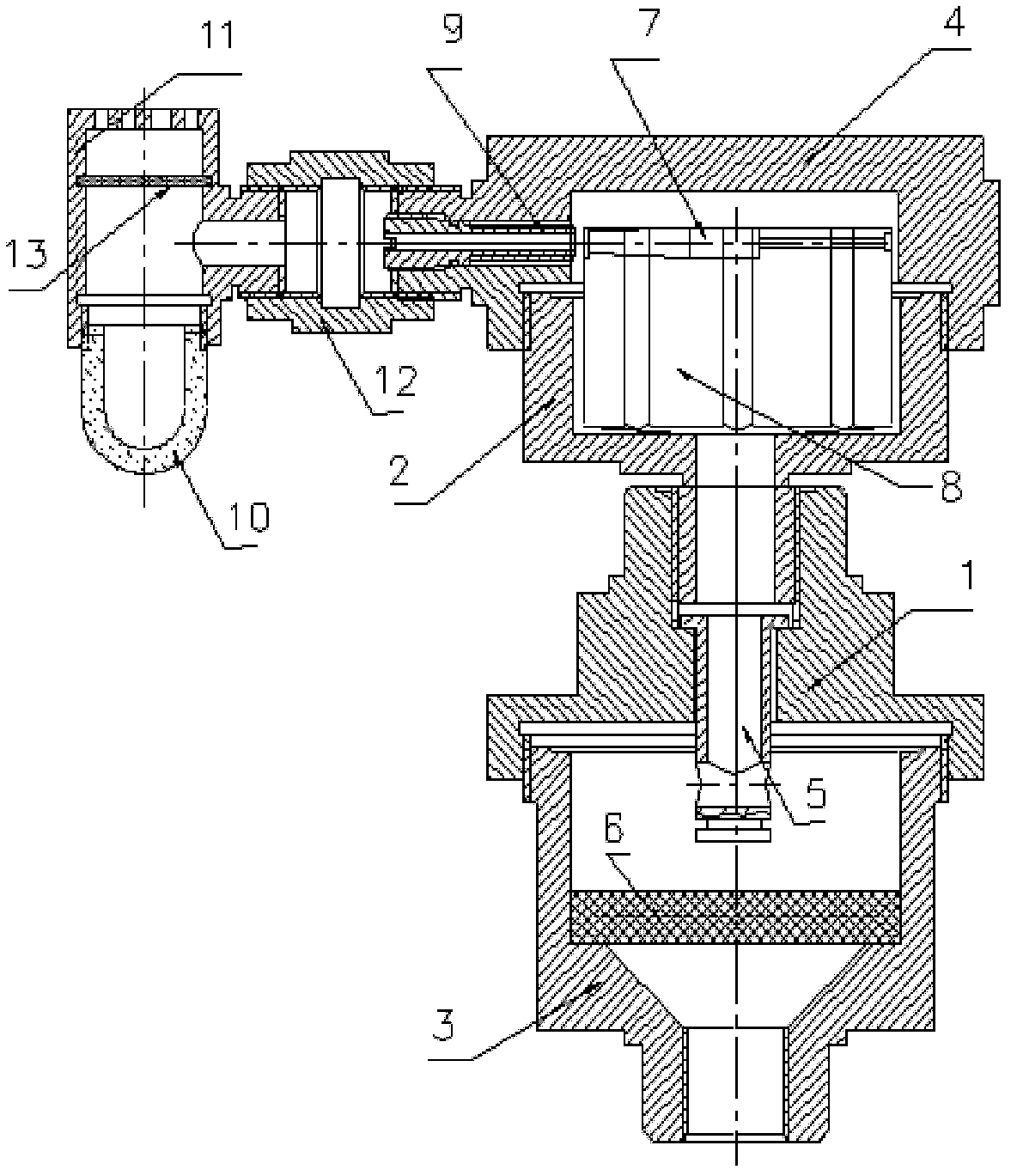

[0016] Such as figure 1 As shown, the gas-liquid separation chamber is set at the bottom of the valve body, which is composed of the valve seat, the lower valve body and the filter screen. In the oil-gas separation chamber, the gas-liquid mixture flows through the mesh filter bed, the gas rises along the drainage channel, and the liquid settles and flows back into the pipe to realize the preliminary oil-gas separation; the air flow removal chamber (exhaust process) is set on the upper part of the valve body, It is composed of drainage body, air float, adjusting polished rod, spring, adjusting screw and upper valve body, etc. It can completely introduce the airflow into the oil mist collection section. ×10 2 Pa gas can be discharged continuously; the oil mist trap is installed on one side of the main valve body, and the oil mist entrained in the gas removal process in the oil mist trap is separated by collision and deposited in the see-through cup. The amount of oil can monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com