System and process of screen pipe completion and cross oil layer cementing for steam injection heavy oil well

A technology of screen tube completion and steam injection, applied in wellbore/well components, flushing wellbore, producing fluid, etc., can solve problems such as blockage, and achieve the effect of expanding the scope of application, short construction time, and high pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

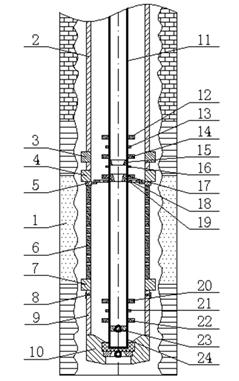

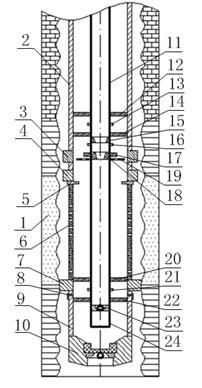

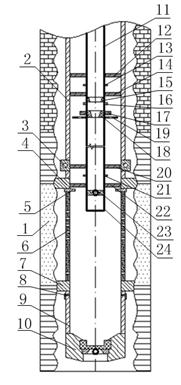

[0060] The present invention will be further described below in conjunction with accompanying drawing:

[0061] For example, in a thermal recovery wellbore with a diameter of 215.9 mm, a cementing and completion pipe string spanning oil layers with a thermal screen 6 with a diameter of 177.8 mm is run, as shown in figure 1 As shown, the steam injection heavy oil well screen completion cross-reservoir cementing system includes a completion string and a cementing string arranged inside the completion string, and the completion string includes sequentially from bottom to top Connected floating shoe 10, sand settling pipe 9, pressure limiting sliding sleeve 8, high temperature resistant packer at the lower end of the screen pipe 7, heat sensitive screen pipe 6, boss positioning seat 5, high temperature resistant packer at the upper end of the screen pipe 4, cement Injection device 3 and sleeve pipe 2; the cementing pipe string includes an insert joint 24, a one-way valve 23, a cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com