Super-deep underground continuous wall and construction method thereof

A technology of underground diaphragm wall and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., to achieve the effect of excellent groove quality, fast and efficient groove formation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

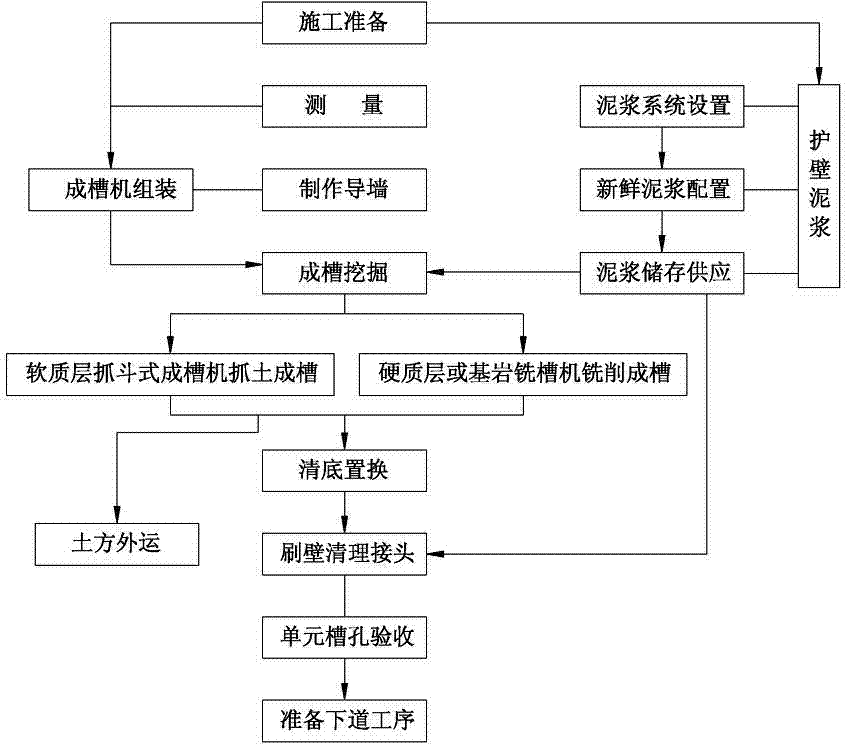

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

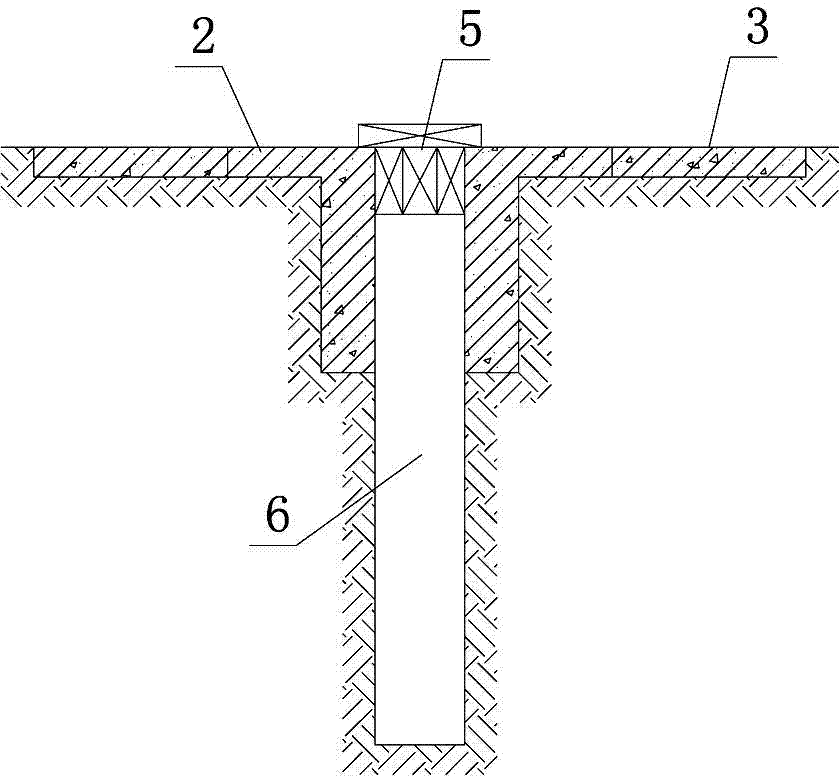

[0025] The ultra-deep underground diaphragm wall, the specific plan is: include a diaphragm wall body 1, and guide walls 2 are symmetrically arranged on both sides of the wall body 1, the cross-sectional shape of the guide wall is "L", and the lower end of the guide wall is located at 4 On the underground rock and soil, the ear side of the guide wall is connected with the concrete pavement 3 . Concrete pavement 3 has a width of 9m, a gravel base layer with a thickness of 200mm, and 50mm gravel on it, and a surface layer of C25 concrete with a thickness of 200mm. Both are 250mm. The width of the guide wall is 40mm wider than the design width d of the continuous wall, and the height of the guide wall is ≥1500mm. The distance between them is 300mm, and the guide wall is provided with a 200mm chamfer at the corner.

[0026] The invention a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com