Negative pressure drilling system

A negative pressure, hydraulic drilling rig technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of difficult to meet the environmental sanitation standards, high gas concentration in the jet stream, poor dust suppression effect, etc., to achieve dust removal Improved effect, easy processing and manufacturing, and the effect of ensuring the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

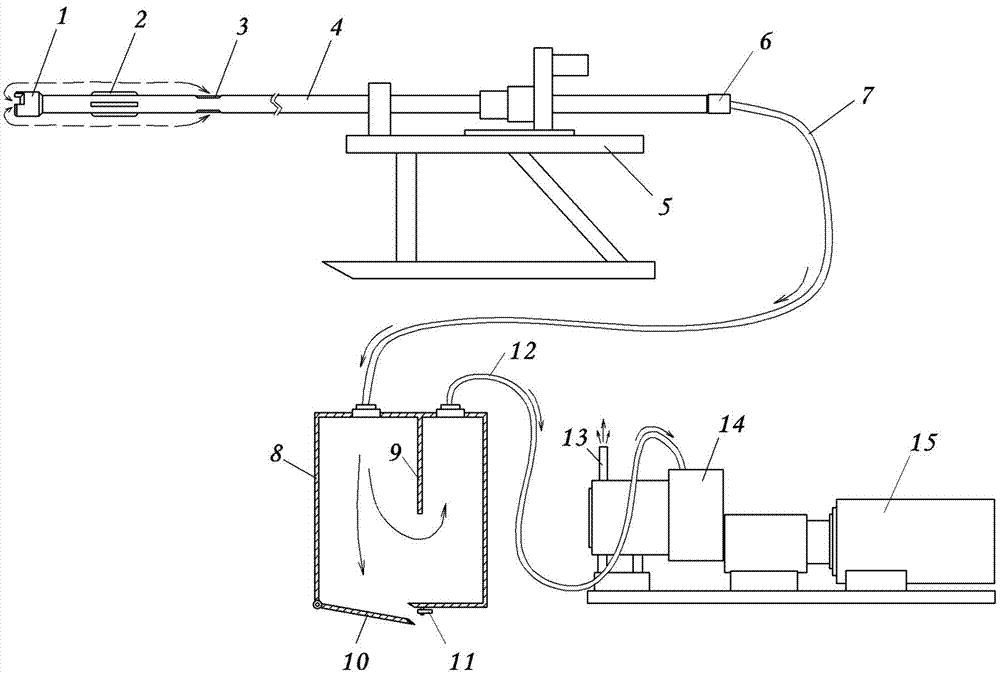

[0013] The rear end of the drill pipe 4 is connected with the dust extraction pipe 7 through the rotary connection device 6, and the dust extraction pipe 7 is communicated with a suction box 8.

[0014] The air suction box 8 is a sealed box, the upper side of the air suction box 8 is provided with a partition 9, the partition 9 divides the air suction box into a particle deposition chamber and an air flow chamber, and the air inlet of the suction box 8 is located above the particle deposition chamber. The air outlet of the box is located above the airflow chamber, and a dust discharge channel is provided below the particle deposition chamber, such as the dust discharge baffle 10 hinged on one side of the box as shown in the figure and the lock for fixing the dust discharge baffle Tighten the knob 11, and the edge of the dust discharge baffle or the dust discharge port can be provided with a rubber sealing strip.

[0015] The air outlet on the air exhaust box 8 upper end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com