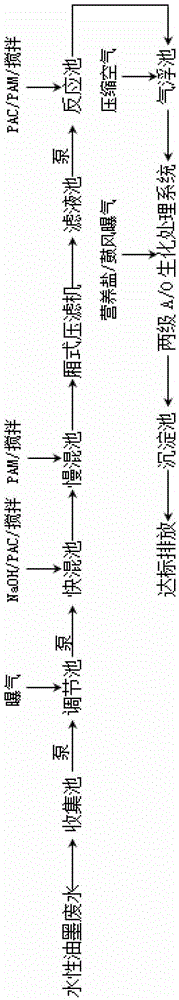

Water-based ink wastewater treatment process

A technology for water-based ink and wastewater treatment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high water-based ink wastewater treatment costs and difficult discharge standards, and achieve The effect of reducing the cost of operating chemicals, less investment in equipment, and reducing the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: a kind of water-based ink wastewater treatment process is carried out according to the following steps:

[0034] A. Collect the water-based ink wastewater into the collection pool, pump the water-based ink wastewater in the collection pool into the adjustment pool, and aerate the wastewater in the adjustment pool; pump the water-based ink wastewater that has been thoroughly mixed in the adjustment pool into the quick mixing pool , use a mechanical diaphragm metering pump to quantitatively add 0.3-0.5g / L coagulant polybasic aluminum chloride (PAC) and stir quickly. You can add coagulant (such as sodium hydroxide) at the same time when adding coagulant; Then the wastewater enters the slow mixing tank, and then the flocculant polyacrylamide (PAM) is added under the condition of slow stirring to convert the suspended particles and colloids of organic pollutants such as acrylic resin in the wastewater into large suspended particles visible to the naked eye.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com