Novel rolling prebending device

A new type of pre-bending technology, used in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as scratching the surface of wire rods, and achieve the effect of eliminating scratches and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

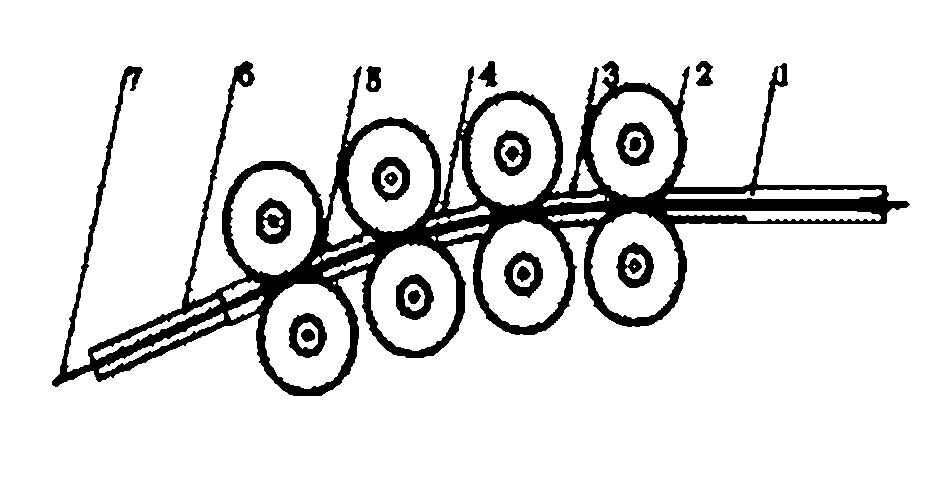

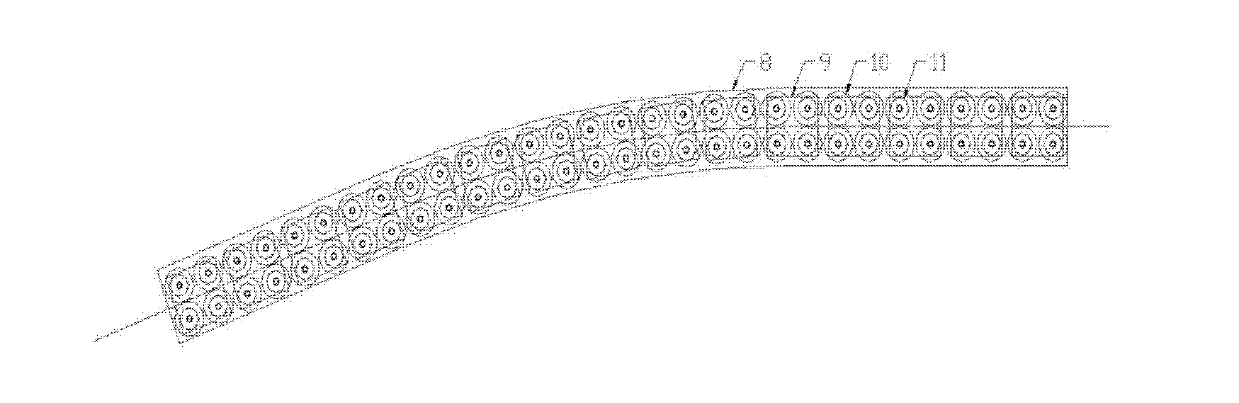

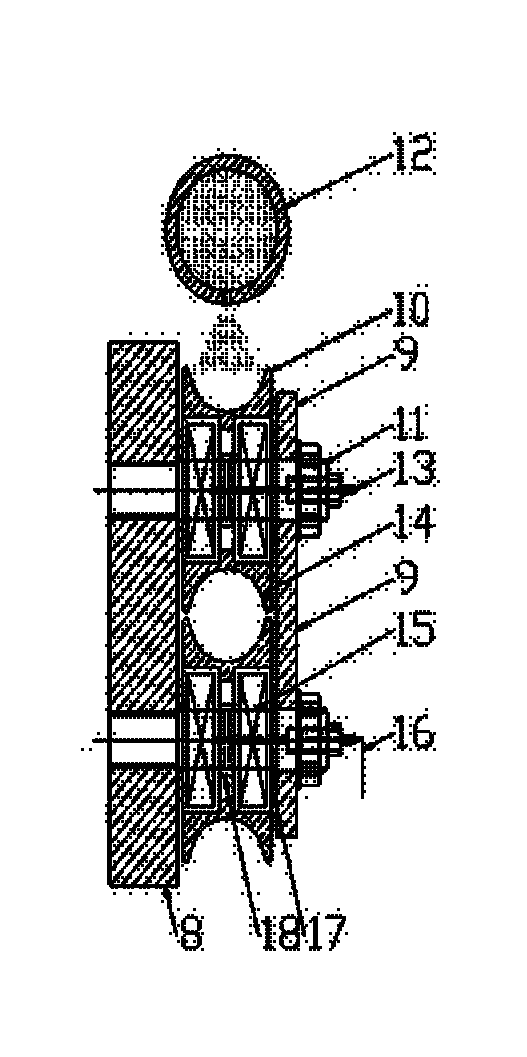

Method used

Image

Examples

Embodiment 1

[0035] The size of the finished wire rod is 4.5mm-7.0mm, and the diameter of the designed guide roller pass is 10.5mm corresponding to it, and the number of guide rollers is 84; there is no scratch on the surface of the finished wire rod after bending.

Embodiment 2

[0037] The size of the finished wire rod is 7.5mm~14.0mm, the diameter of the designed guide roller is 17.5mm, and the number of guide rollers is 84; there is no scratch on the surface of the finished wire rod after bending.

Embodiment 3

[0039] The size of the finished wire rod is 14.5mm-25.0mm, the diameter of the designed guide roller is 30.0mm, and the number of guide rollers is 60; there is no scratch on the surface of the finished wire rod after bending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com