Low-content supported ruthenium-palladium bimetal hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, supported technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high usage, high cost of catalyst materials, single metal It can improve and improve the catalytic selective hydrogenation performance of materials, reduce the cost of materials, and reduce the consumption of precious metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

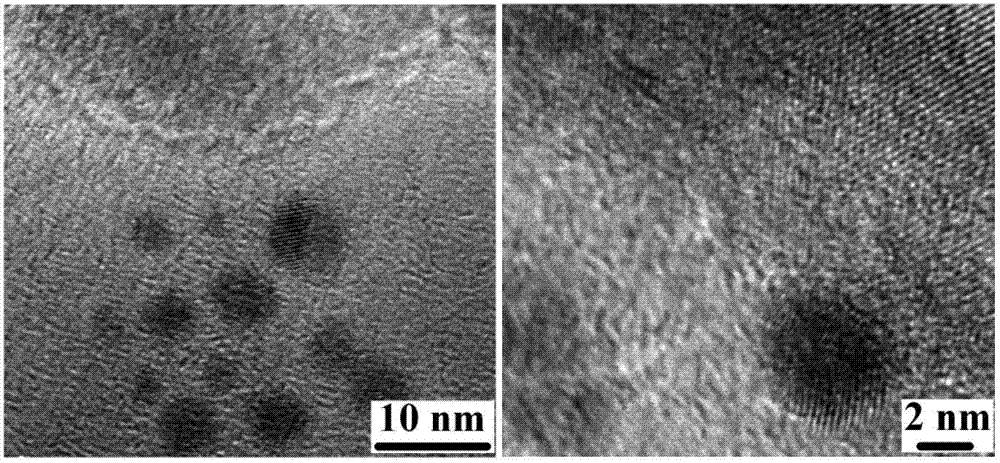

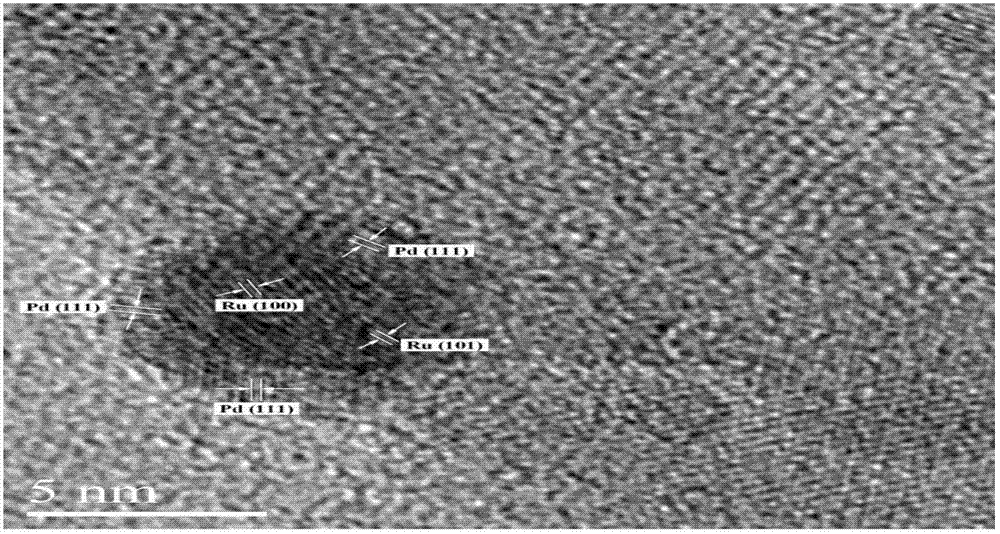

Embodiment 1

[0024] Measure 5.4g of spherical θ-Al with a volume of 11ml and a particle size of 20-40 mesh 2 o 3 , placed in 12ml of a mixed solution of ruthenium nitrate and palladium nitrate, the mass ratio of ruthenium nitrate and palladium nitrate is 1:1, the total concentration of metal ions is 0.013mol / L, ultrasonic treatment at 25°C for 12h, and then cooling, After washing and filtering, drying at 70°C for 6h, and then calcining at 450°C for 8h to obtain a low-content supported ruthenium-palladium bimetallic nanocatalyst Ru-Pd / Al 2 o 3 , the mass ratio of active metal ruthenium and palladium in the catalyst measured by inductively coupled plasma emission spectroscopy is 19:21, and the total content is 0.28wt%.

[0025] Based on the liquid phase reactor evaluation device, weigh 0.5g Ru-Pd / Al 2 o 3 , placed in 10ml of deionized water, adding sodium hydroxide to adjust the pH to 10; adding 10 drops of fresh sodium borohydride aqueous solution, the concentration of sodium borohydrid...

Embodiment 2

[0028] Measure 8.5g volume and be 17ml particle size be 40-60 purpose clover-shaped η-Al 2 o 3 , placed in 16ml of ruthenium chloride solution with a concentration of 0.005mol / L, ultrasonically treated at 45°C for 24h, then cooled, washed and filtered, then dried at 40°C for 12h, and then the obtained dry solid Place in 16ml of palladium nitrate solution with a concentration of 0.01mol / L, ultrasonically treat at 45°C for 24h, then cool, wash and filter, dry at 40°C for 12h, and finally at 500°C Calcination treatment for 6h to obtain low-content supported ruthenium-palladium bimetallic nanocatalyst Ru-Pd / Al 2 o 3 , the mass ratio of active metal ruthenium and palladium in the catalyst measured by inductively coupled plasma emission spectrometry is 19:39, and the total content is 0.29wt%.

[0029] Based on the liquid phase reactor evaluation device, weigh 0.4gRu-Pd / Al 2 o 3 , put in 5ml deionized water, add sodium hydroxide to adjust the pH to 8; add dropwise 5 drops of fre...

Embodiment 3

[0032] Measure 12.5g volume of 25ml flake δ-Al with a particle size of 10-30 mesh 2 o 3 , placed in a mixed solution of 24ml of ruthenium chloride and palladium chloride, wherein the mass ratio of ruthenium chloride and palladium chloride is 2:1, the total molar concentration of metal is 0.01mol / L, ultrasonic treatment at 30°C 12h, after cooling, washing and filtering, drying at 50°C for 10h, and finally calcining at 400°C for 6h to obtain a low-content supported ruthenium-palladium bimetallic nanocatalyst RuPd / Al 2 o 3 , the mass ratio of active metal ruthenium and palladium in the catalyst was measured by inductively coupled plasma emission spectrometry to be 40:19, and the total content was 0.19wt%.

[0033] Based on the liquid phase reactor evaluation device, weigh 0.5g RuPd / Al 2 o 3 , put in 15ml deionized water, add sodium hydroxide to adjust the pH to 11; add dropwise 12 drops of fresh sodium borohydride aqueous solution (concentration: 800g / L), stir for 50min, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com