Oil-water separation mesh film with acid-base salt stabilizing function and with underwater super-oleophobic property and preparation method thereof

An oil-water separation mesh membrane and a hydrophilic polymer technology are applied in the field of oil-water separation mesh membrane and its preparation, which can solve the problems of loss of oil-water separation, easy dissolution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

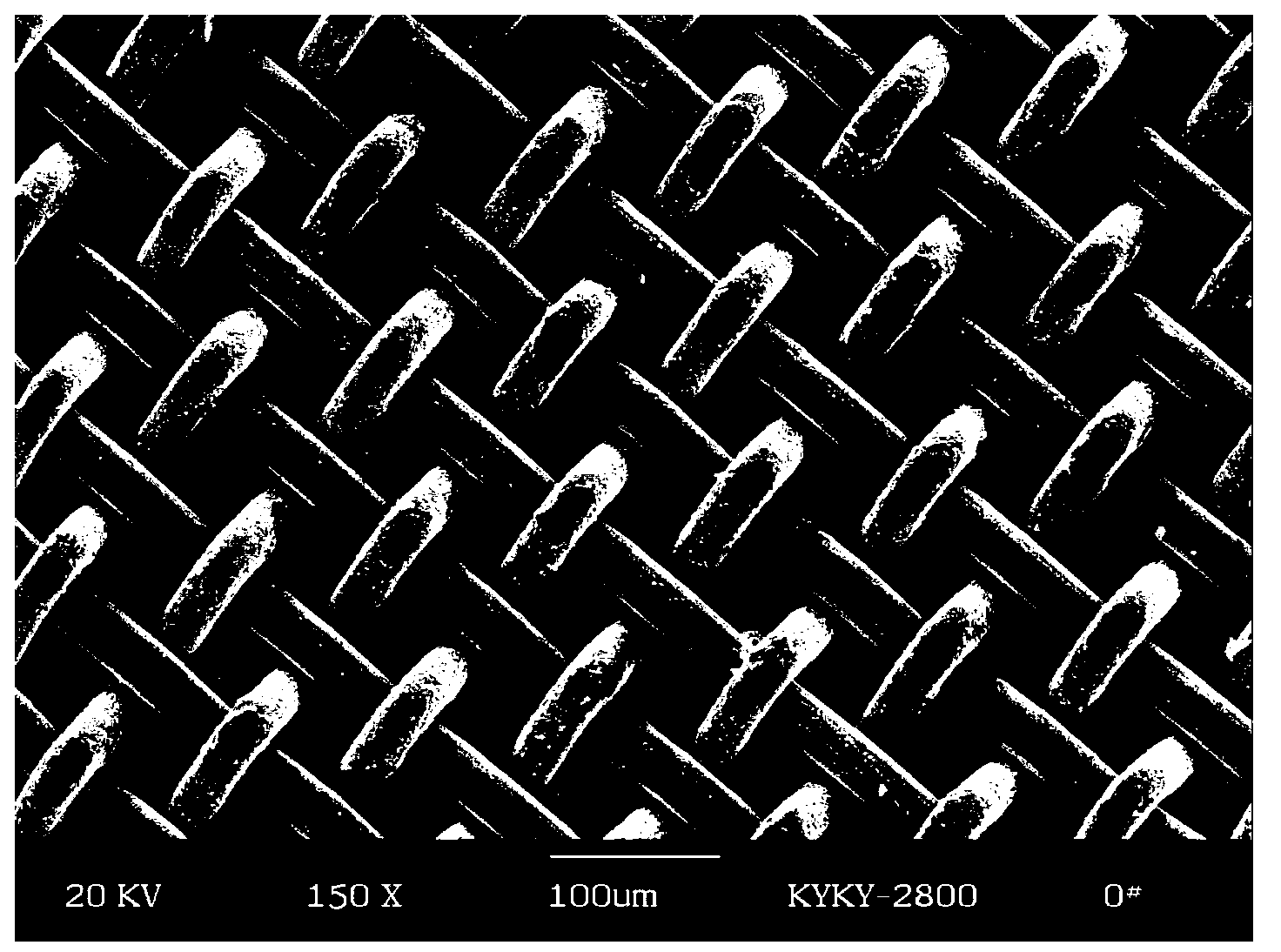

[0037] Embodiment 1, preparation coats the oil-water separation omentum of modified chitosan polyvinyl alcohol mixture

[0038] (1) immerse the 300-mesh copper mesh in ethanol and acetone and ultrasonically clean each for 5 minutes, soak in hydrochloric acid for 1 hour, deposit copper particles by electrochemical deposition, increase its roughness, and dry at room temperature;

[0039] (2) At normal temperature, add 100ml of water, 2ml of glacial acetic acid, and 2g of chitosan (80%-95% degree of deacetylation) into a 250ml beaker, stir and mix evenly to obtain a 2% chitosan solution.

[0040] (3) add 100ml water, 6g polyvinyl alcohol (molecular weight is 1750) in 250ml round bottom flask, reflux 1 hour at 90 ℃, be cooled to room temperature, obtain 6% polyvinyl alcohol solution, above-mentioned chitosan solution and The polyvinyl alcohol solution is uniformly mixed according to the mass ratio of 4:1 to obtain a mixed solution.

[0041] (4) Dip the copper grid obtained in ste...

Embodiment 2

[0047] Embodiment 2, preparation coats the oil-water separation omentum of modified chitosan / carboxymethyl cellulose mixture

[0048] (1) immerse the 300-mesh nylon net successively in ethanol and acetone and ultrasonically clean it for 5 minutes, soak it in hydrochloric acid for 1 hour, and dry it at room temperature;

[0049] (2) At normal temperature, add 100ml of water, 2ml of glacial acetic acid, and 2g of chitosan (80%-95% degree of deacetylation) into a 250ml beaker, stir and mix evenly to obtain a 2% chitosan solution.

[0050] (3) Use a 250ml beaker to configure a viscous aqueous solution of carboxymethylcellulose with a mass concentration of 5%. The chitosan solution and the carboxymethyl cellulose solution are uniformly mixed according to the mass ratio of 5:1 to obtain a mixed solution.

[0051] (4) Dip the nylon mesh obtained in step (1) into the mixed solution obtained in step (3), keep it for 30 minutes, and then take it out to dry.

[0052] (5) The net that s...

Embodiment 3

[0057] Embodiment 3, preparation coats the oil-water separation omentum of modified chitosan

[0058] (1) immerse the 300-mesh steel wire mesh successively in ethanol and acetone for ultrasonic cleaning for 5 minutes, soak in hydrochloric acid for 1 hour, and then immerse in concentrated sulfuric acid for 1 hour to form a stable hydrophilic passivation layer;

[0059] (2) At normal temperature, add 100ml of water, 2ml of glacial acetic acid, and 2g of chitosan (80%-95% degree of deacetylation) into a 250ml beaker, stir and mix evenly to obtain a 2% chitosan solution.

[0060] (3) dip the steel wire mesh that step (1) obtains in the chitosan solution that step (2) obtains, keep 30min, then take out and dry;

[0061] (4) The net obtained in step (3) is immersed in a 4% sodium hydroxide aqueous solution with a mass concentration of 4%, and kept for 1min, then taken out to dry, immersed in 2% glutaraldehyde solution at 40°C for 30min, fully cross-linked, Wash with deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com