Structure for fuel filler tube opening

A technology of fuel supply and structure, which is applied in the direction of layout combined with internal combustion engine fuel supply, power plant, transportation and packaging, etc., can solve problems such as falling, and achieve the effect of easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

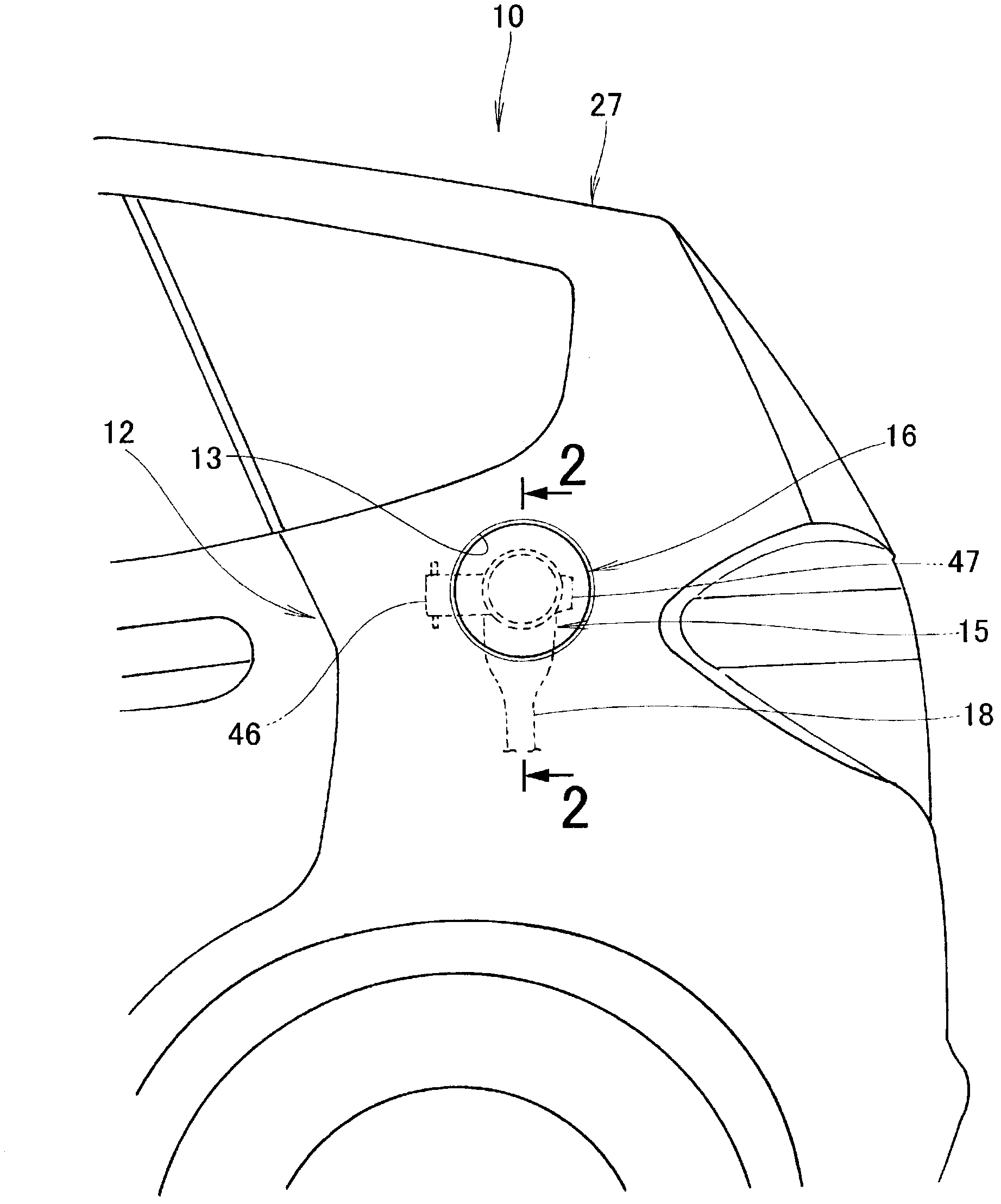

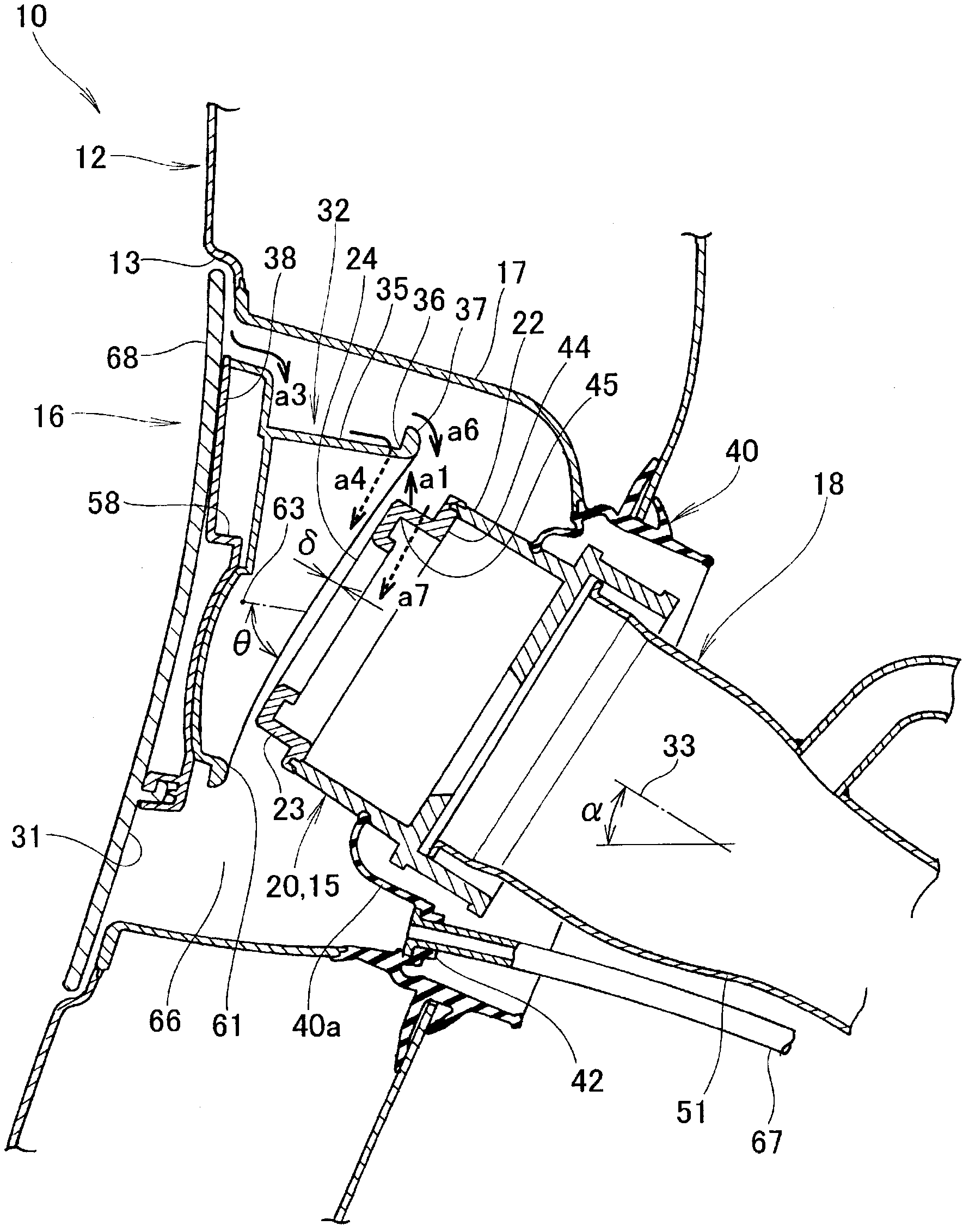

[0032] like figure 1 As shown, a fuel supply port structure is adopted in the vehicle 10 . The filler port 15 communicates with the opening 13 formed in the side body 12 of the body 27 . The opening 13 is openably and closably covered by a fuel filler cap 16 via a hinge 46 provided on the side body 12 . The filler port 15 is composed of a filler cap 16 and a mouth piece 20 of the fuel introduction pipe 18 .

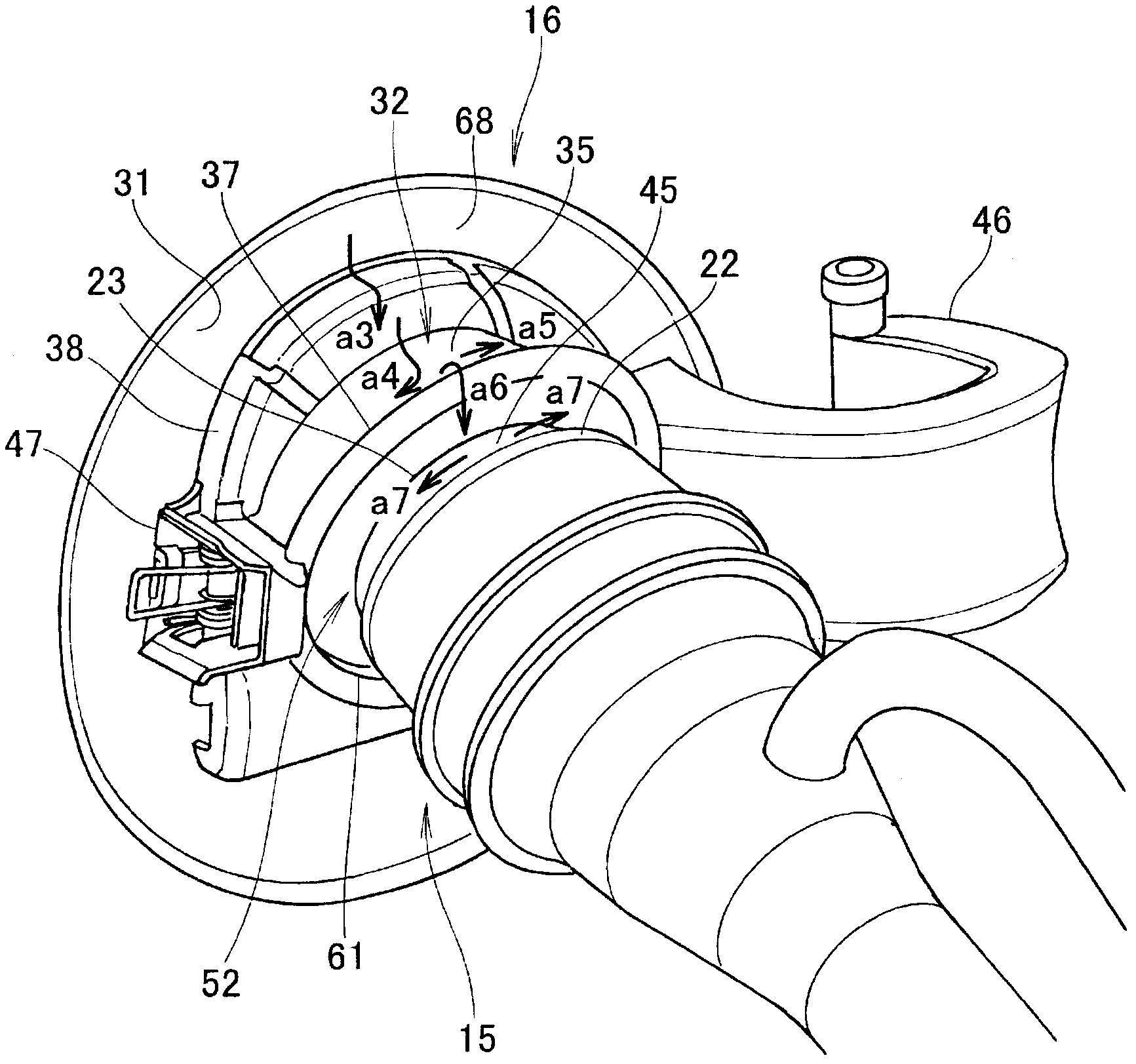

[0033] like figure 2 As shown, the fuel introduction pipe 18 is composed of a filler pipe 51 and a mouthpiece 20 provided at one end of the filler pipe 51 . The mouthpiece 20 forms the filler opening 15 . The other end of the filler pipe 51 communicates with an unshown fuel tank.

[0034] One end edge portion of a cylindrical fuel adapter 17 protruding inwardly of the vehicle body is attached to the opening portion 13 . The mouthpiece 20 is disposed in the opening at the other end of the fuel adapter 17 .

[0035] The mouthpiece 20 is composed of a first mouthpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com