Monte carlo simulation method for forecasting free radical polymerization in microtube reactor

A Monte Carlo simulation, tubular reactor technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. The effect of consuming time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Figure 1 is a schematic diagram of the device of Example 1. Materials enter from 1 and exit from N. The length of material flowing in the tube is equal to the total length of the microtube.

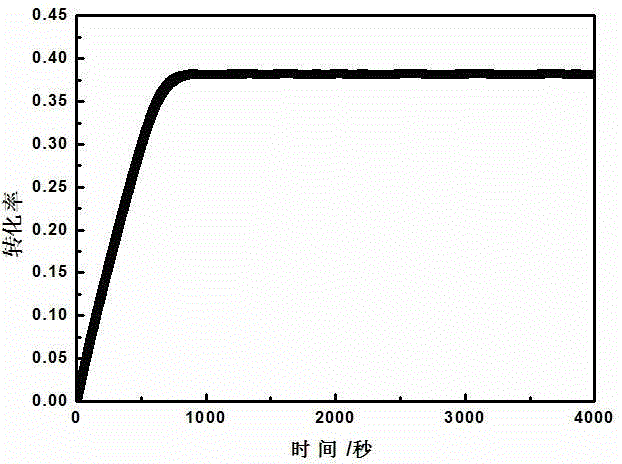

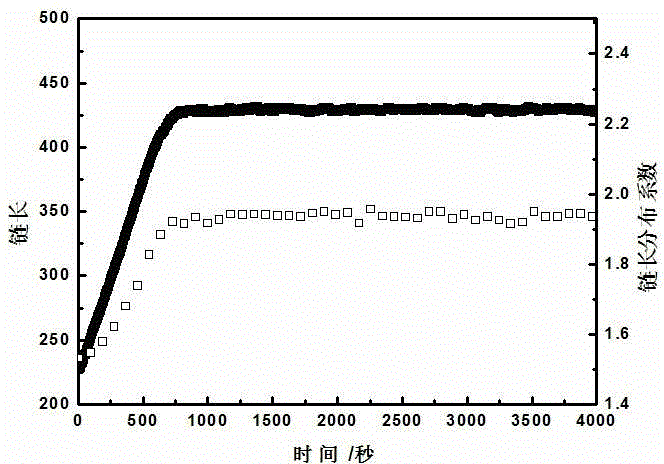

[0049] Under the simulated temperature of 54℃, acrylonitrile (AN), itaconic acid (Itaconic acid) and methyl acrylate (MA) were radically terpolymerized in a microtubular reactor, and the solvent was 40% sodium thiocyanate aqueous solution.

[0050] The specific implementation steps are as follows:

[0051] (1) Determine all elementary reactions and diffusion reactions in the polymerization system,

[0052] A. Redox reaction produces two primary free radicals;

[0053] B. Addition of primary free radicals to acrylonitrile, itaconic acid, and methyl acrylate to generate acrylonitrile growth free radicals, itaconic acid growth free radicals, and methyl acrylate growth free radicals, a total of 3 elementary reactions;

[0054] C. Acrylonitrile growth free radicals, itaconic acid gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com