Preparation method of gastric-soluble coating material polyacrylic resin IV

A technology of polyacrylic acid resin and stomach-soluble type, which is applied in the field of preparation of polyacrylic acid resin Ⅳ, which can solve the problems of inapplicable direct refining steps and low processing performance, so as to improve the reactivity of monomers, reduce the reaction temperature and shorten the reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

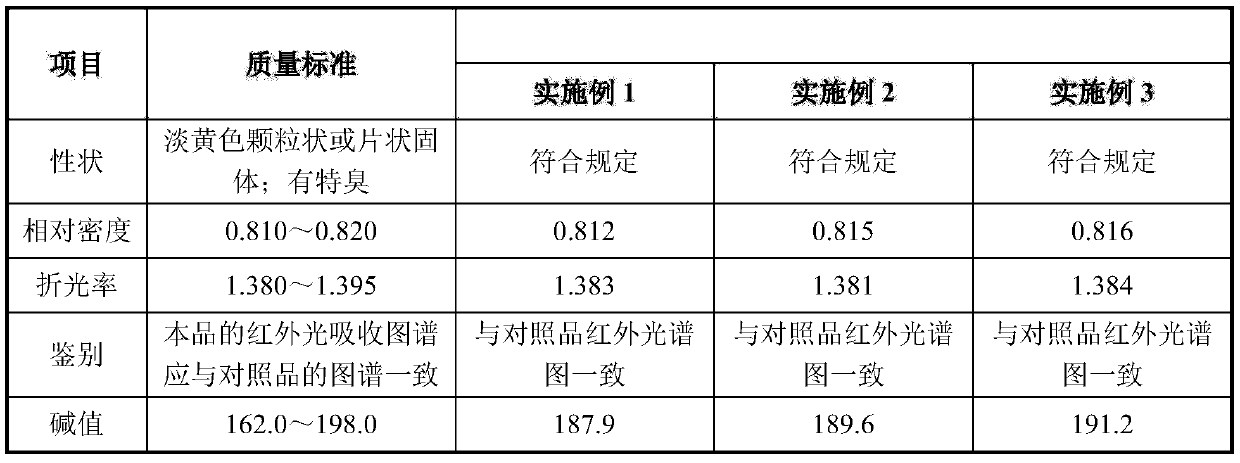

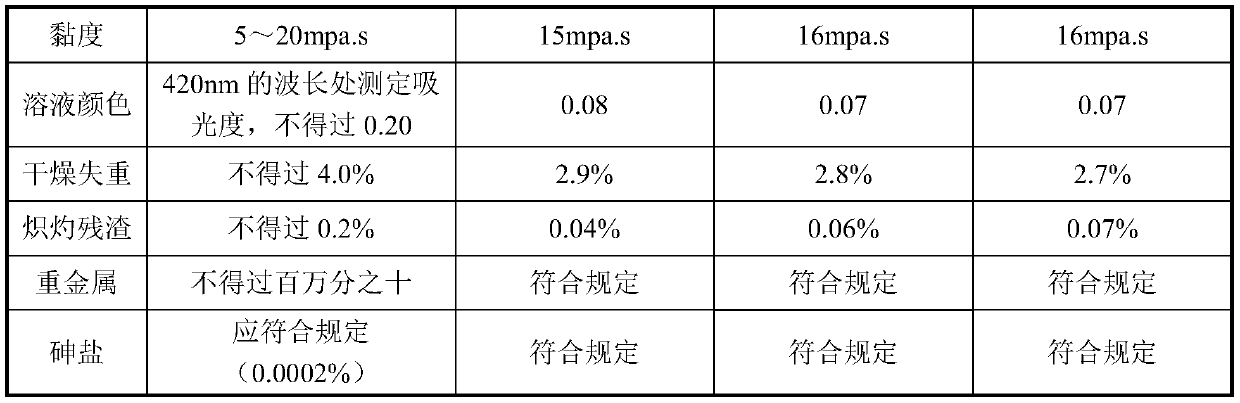

Examples

Embodiment 1

[0043] (1) Raw materials:

[0044] 100g of methyl methacrylate, 105g of butyl methacrylate, 205g of dimethylaminoethyl methacrylate;

[0045] Emulsifier: sodium lauryl sulfonate 1.0g; soy lecithin 2g;

[0046] Initiator: 10g of azobisisobutyronitrile;

[0047] Catalyst: 0.2g of titanium glycol

[0048] The balance: 577g of ethanol

[0049] Pretreatment: Add the butyl methacrylate that needs to be washed into the butyl methacrylate treatment tank, and then add a 5% NaOH solution with a volume of about 1 / 3-1 / 5 of the butyl methacrylate treatment tank, stir well, and let stand for separation After layering, release the lower layer liquid, add the same amount of NaOH solution, and wash in the same way.

[0050] Add the methyl methacrylate that needs to be washed into the methyl methacrylate treatment tank, and then add a 5% NaOH solution with a volume of about 1 / 3-1 / 5 of it, stir it well, and let it stand for layering. Discharge the lower layer, then add the same amount of NaOH solution, wa...

Embodiment 2

[0053] 120g of methyl methacrylate, 120g of butyl methacrylate, 240g of dimethylaminoethyl methacrylate;

[0054] Emulsifier: sodium lauryl sulfonate 2g; soy lecithin 3g;

[0055] Initiator: 8g of azobisisoheptonitrile;

[0056] Catalyst: 1.0g of titanium glycol,

[0057] The balance: 500g isopropanol

[0058] According to Example 1, methyl methacrylate and butyl methacrylate were pretreated.

[0059] Inhale 480g of isopropanol into the reaction kettle, first add 240g of dimethylaminoethyl methacrylate, the ultrasonic power is 500W, shake to dissolve, first add 60g of methyl methacrylate and 60g of butyl methacrylate, add the catalyst 0.2g of titanium ethylene glycol and 1.0g of sodium lauryl sulfonate as emulsifier; 2g of soy lecithin. Under ultrasonic vibration, dissolve 8g of azobisisoheptaonitrile in 20g of isopropanol and press 1ml / min Add the initiator azobis-isoheptanonitrile solution at a uniform rate, and when the initiator is added about one-half, start to add the remaining m...

Embodiment 3

[0061] 110g of methyl methacrylate, 110g of butyl methacrylate, 220g of dimethylaminoethyl methacrylate;

[0062] Emulsifier: sodium lauryl sulfonate 1.5g; natural emulsifier 1.5g;

[0063] Initiator: azobisisobutyronitrile 5g;

[0064] Catalyst: 0.6g of titanium glycol;

[0065] The balance: acetonitrile 550g

[0066] According to Example 1, methyl methacrylate and butyl methacrylate were pretreated.

[0067] Suction 520g acetonitrile into the reaction kettle, first add 220g dimethylaminoethyl methacrylate, the ultrasonic power is 600W, shake to dissolve it, first add 55g methyl methacrylate and 55g butyl methacrylate, add the catalyst ethylene dichloride 0.6g of titanium alkoxide and 1.5g of sodium dodecyl sulfonate as emulsifier; 1.5g of soybean lecithin. Under ultrasonic vibration, dissolve 5g of azobisisoheptonitrile in 30g of isopropanol at a rate of 1ml / min Add the initiator azobisisobutyronitrile solution at a uniform speed, and when the initiator is added about one-half, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com