Graphene film humidity sensor

A humidity sensor, graphene film technology, applied in the direction of material resistance, can solve the problems of film formation and agglomeration, affecting the uniformity and quality of the film, and achieve the effects of fast response, low cost and strong adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

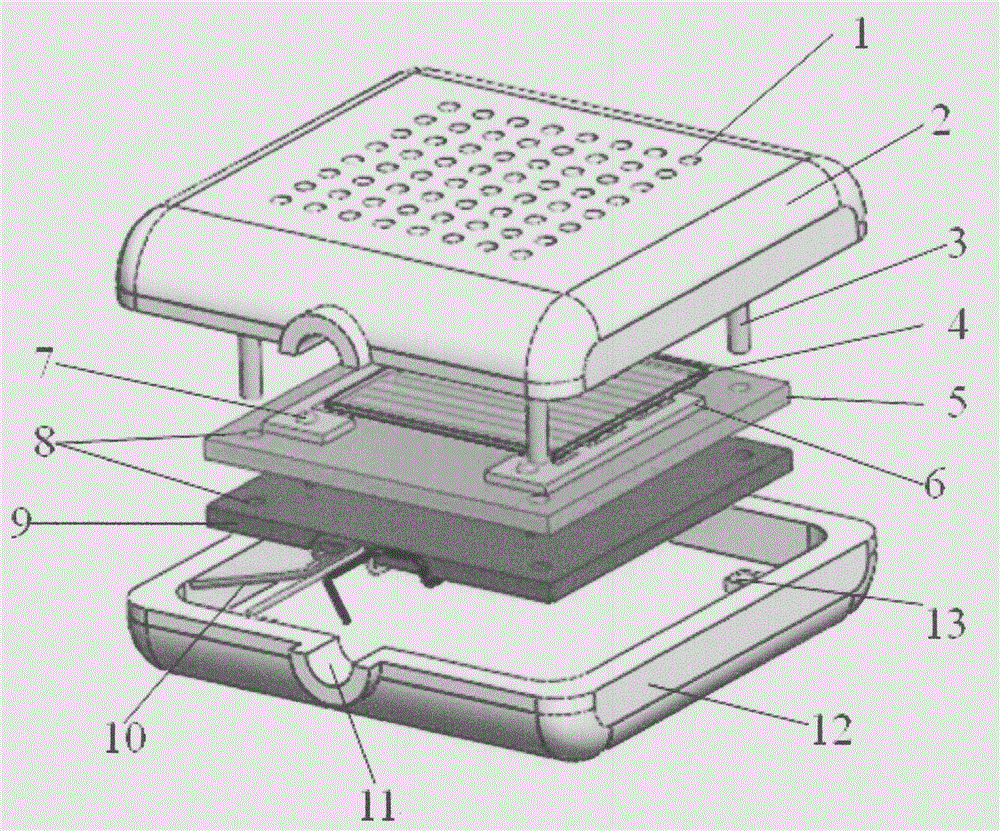

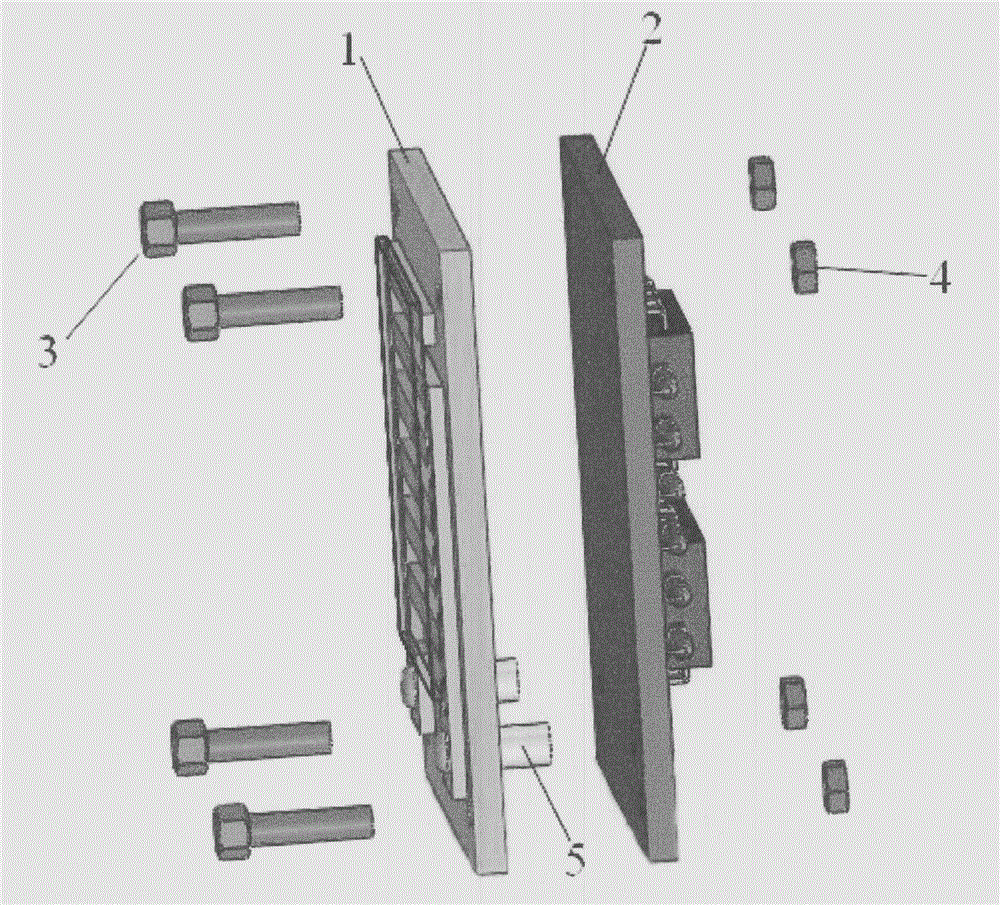

[0023] see figure 1 , the embodiment of the present invention is provided with flexible polymer substrate 5, comb-shaped interdigitated electrode 6, graphene-based moisture-sensitive film 4, resistance pick-up circuit board 9, electrode pin 7, air-permeable housing 2 and 12, lead hole 11, Fixed screw hole 8, fixed screw rod 3 and nut 13.

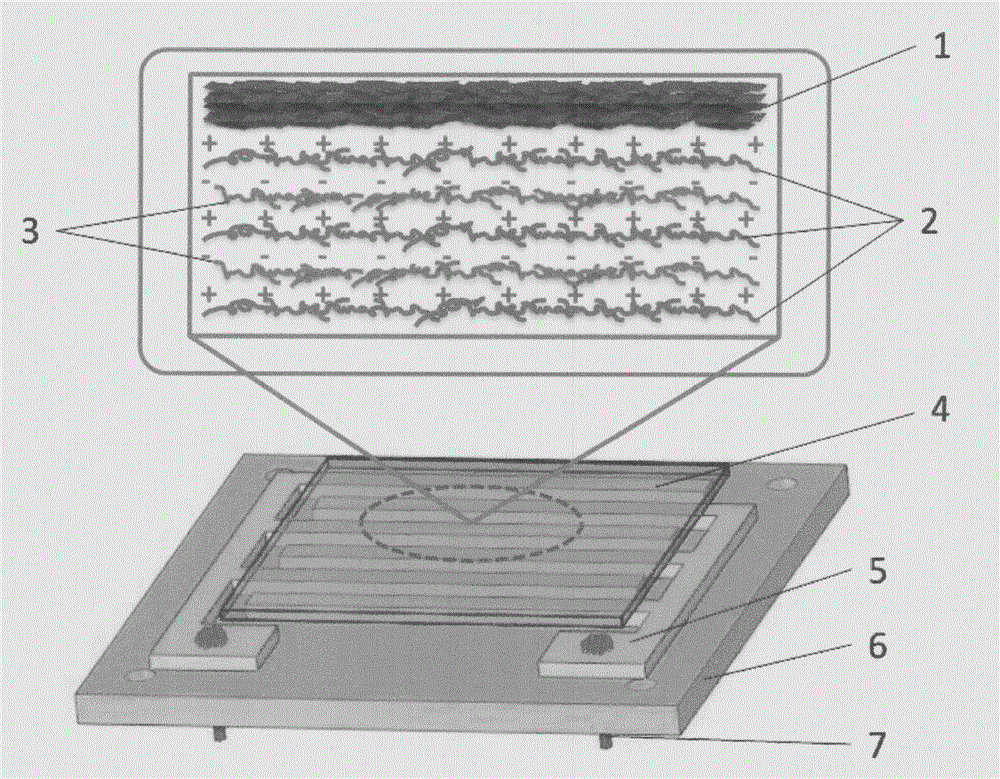

[0024] A flexible polymer substrate made of polyimide, on which a comb-like interdigitated electrode pattern is prepared by photolithography and evaporation. Electrostatically induced self-assembly method is used to prepare polyelectrolyte film layer on the surface of flexible polymer substrate and comb-shaped interdigitated electrode as a leading layer, and then solvent evaporation-induced self-assembly method is used to prepare graphene film to form a humidity-sensitive film sensor element, such as figure 2 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com