Method for hydrolyzing egg-white proteins by various proteases

A protease hydrolysis, egg white protein technology, applied in the direction of fermentation, can solve problems such as amino acid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

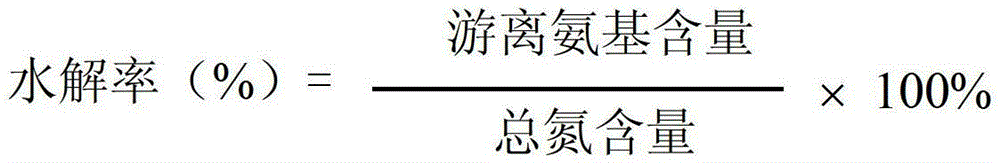

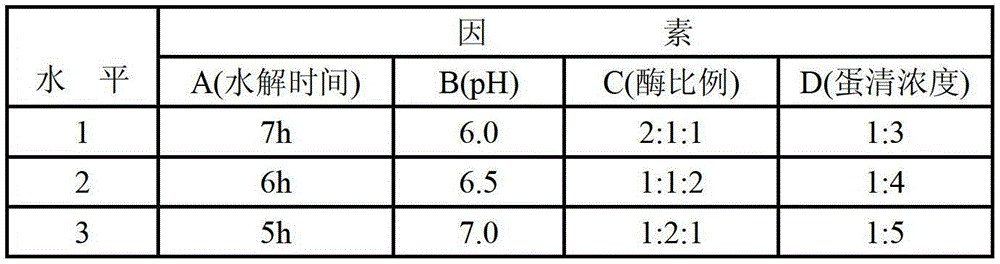

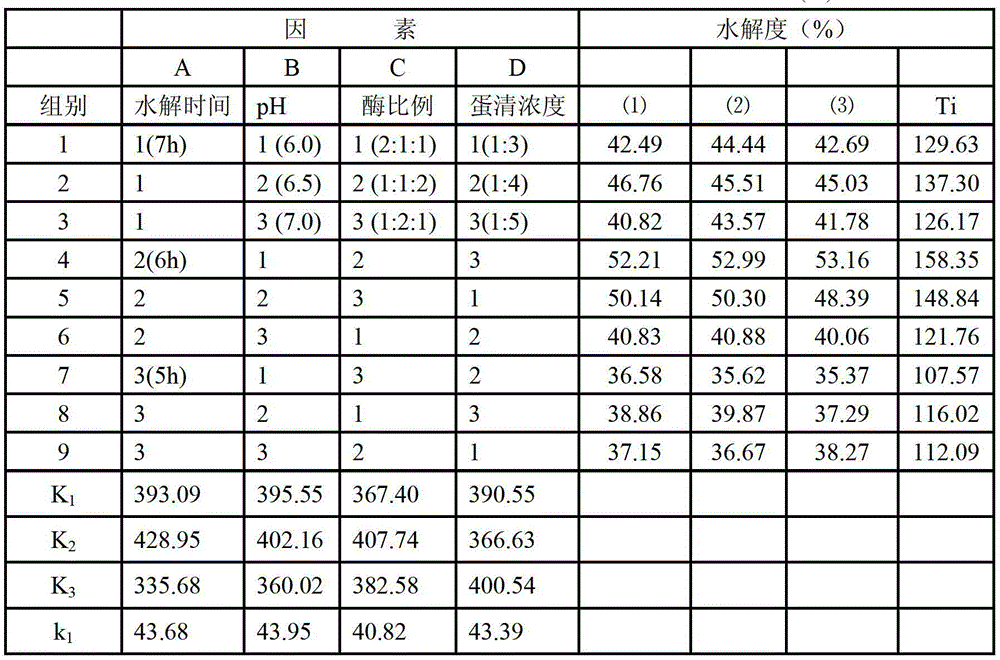

Method used

Image

Examples

example 1

[0021] Example 1: Using the egg white raw material as the substrate for enzymatic hydrolysis, add compound protease (Protamex), neutral protease (Neutrase), and flavor protease (Flavourzyme) to hydrolyze simultaneously to obtain egg white protein hydrolyzate.

[0022] Adjust the egg white concentration to 1:5 (egg white volume:distilled water volume), adjust the pH to 6.5 with HCl, preheat the water bath to 55°C, add 1.5% protease (Protamex), 1.5% neutral protease (Neutrase), flavor protease (Flavourzyme) 3.0% (accounting for the weight of the diluted egg white), carry out the enzymolysis reaction in a constant temperature water bath shaker (120r / min), monitor the pH of the egg white solution with a pH meter during the enzymolysis reaction, and add NaOH solution dropwise Adjust the pH to keep the pH at 6.5. After 6 hours of reaction, collect the egg white protein hydrolyzate, put it in a boiling water bath to inactivate the enzyme for 20 minutes, and terminate the enzymolysis r...

example 2

[0034] Example 2: The egg white raw material was used as the substrate for enzymatic hydrolysis, and alkaline protease (Alcalase) and flavor protease (Flavourzyme) were added successively for hydrolysis to obtain egg white protein hydrolyzate.

[0035]Adjust the egg white concentration to 1:5 (volume of pure egg white: volume of distilled water), adjust to pH 7.5 with NaOH, preheat the water bath to 55°C, add 2.0% alkaline protease (Alcalase), and place in a constant temperature water bath shaker (120r / min ) in the enzymolysis reaction, during the enzymolysis reaction, use a pH meter to monitor the pH of the egg white solution, and adjust the pH by dropping NaOH solution to keep the pH at 7.5. After reacting for 3 hours, adjust the pH to 6.0 with NaOH solution to maintain The reaction temperature is 55°C, add 4% flavor protease (Flavourzyme), and carry out the enzymolysis reaction in a constant temperature water bath shaker (120r / min). Adjust the pH to keep the pH at 6.0. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com