Fermentation medium and fermentation method for preparing recombinant human interferon alpha2b

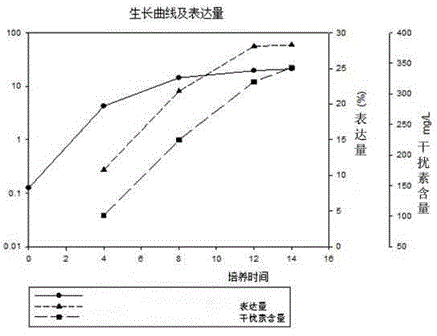

A technology of recombinant human interferon and fermentation medium, which is applied in the field of medicine, can solve problems such as difficult high-density culture, excessive production of acetic acid, and purification burden, and achieves benefits for subsequent purification, fewer metabolic by-products, and high-density culture and efficient expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The components of the fermentation medium are: tryptone 6000g, yeast extract 4000g, disodium hydrogen phosphate 1200g, potassium dihydrogen phosphate 600g, ammonium chloride 100g, sodium chloride 100g, magnesium sulfate 60g, calcium chloride 20g and glycerine Alcohol 3000g.

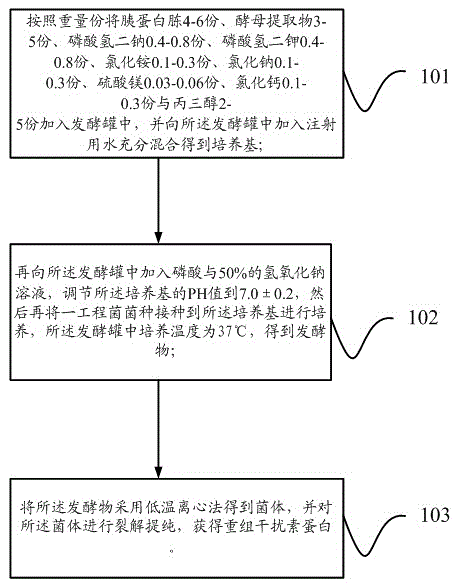

[0044] The fermentation culture method for preparing recombinant human interferon α2b comprises the following steps:

[0045] Make the above-mentioned components into culture medium according to weight;

[0046] In a 300L fermenter, dissolve the culture medium with an appropriate amount of water for injection, and the total volume is constant to 200L;

[0047] Adjust the pH value of the medium to 4.2±0.2 with phosphoric acid, and sterilize at 121°C for 15 minutes;

[0048] Then the culture medium was cooled to 37°C, and the pH value of the culture medium was adjusted to 7.0 ± 0.2 with 50% sodium hydroxide solution, and the seed solution of recombinant human interferon engineering bacteria (pADUA-...

Embodiment 2

[0053] The components of the fermentation medium are: tryptone 6000g, yeast extract 4000g, disodium hydrogen phosphate 1200g, potassium dihydrogen phosphate 600g, ammonium chloride 100g, sodium chloride 100g, magnesium sulfate 60g, calcium chloride 20g and glycerine Alcohol 3000g.

[0054] The fermentation culture method for preparing recombinant human interferon α2b comprises the following steps:

[0055] Make the above-mentioned components into culture medium according to weight;

[0056] In a 300L fermenter, dissolve the culture medium with an appropriate amount of water for injection, and the total volume is constant to 200L;

[0057] Adjust the pH value of the medium to 4.2±0.2 with phosphoric acid, and sterilize at 121°C for 15 minutes;

[0058] Then the culture medium was cooled to 37°C, and the pH value of the culture medium was adjusted to 7.0 ± 0.2 with 50% sodium hydroxide solution, and the seed solution of recombinant human interferon engineering bacteria (pADUA-...

Embodiment 3

[0063] The components of the fermentation medium are: tryptone 6000g, yeast extract 4000g, disodium hydrogen phosphate 1200g, potassium dihydrogen phosphate 600g, ammonium chloride 100g, sodium chloride 100g, magnesium sulfate 60g, calcium chloride 20g and glycerine Alcohol 3000g.

[0064] The fermentation culture method for preparing recombinant human interferon α2b comprises the following steps:

[0065] Make the above-mentioned components into culture medium according to weight;

[0066] In a 300L fermenter, dissolve the culture medium with an appropriate amount of water for injection, and the total volume is constant to 200L;

[0067] Adjust the pH value of the medium to 4.2±0.2 with phosphoric acid, and sterilize at 121°C for 15 minutes;

[0068] Then the culture medium was cooled to 37°C, and the pH value of the culture medium was adjusted to 7.0 ± 0.2 with 50% sodium hydroxide solution, and the seed solution of recombinant human interferon engineering bacteria (pADUA-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com