Preparation method of aluminum phenylphosphinate

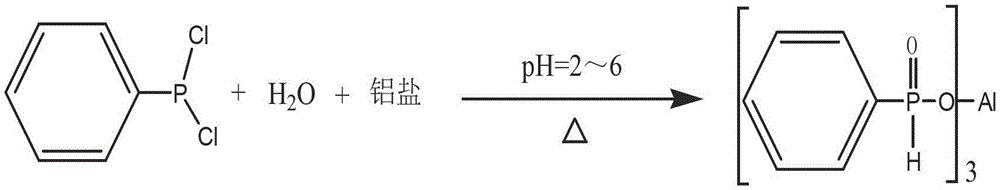

A technology of aluminum phenylphosphinate and aluminum sulfate, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of improving the requirements of feeding equipment and the instability of aluminum chloride hydrolysis , Reduce the utilization rate of aluminum ions and other issues, achieve good hydrolysis stability, suitable for industrial production, and convenient reaction treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

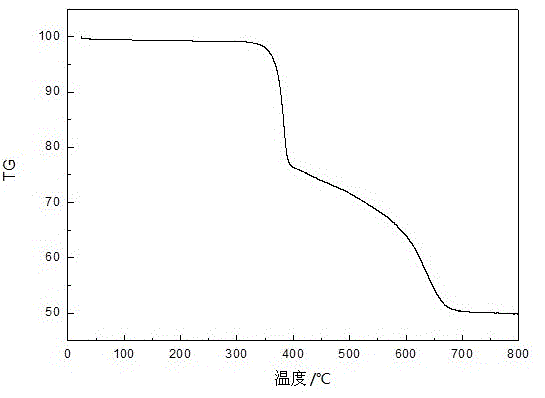

[0033] Add 21.48 g of phenylphosphine dichloride to a 500 ml four-necked flask equipped with a serpentine reflux condenser, an electric stirrer and an acid absorption tower.

[0034] Weigh 15g of aluminum nitrate nonahydrate and dissolve it in 200g of water. Under stirring conditions, slowly drop the aluminum nitrate solution into phenylphosphine dichloride at a temperature range of 0-5°C, adjust the pH to 2-6, heat to 85°C, and react at a constant temperature for 1.5h to obtain a white precipitate, filter and wash , Drying can get white powder product aluminum phenyl phosphinate. The yield was 92.2%.

Embodiment 2

[0036] Add 21.48 g of phenylphosphine dichloride to a 500 ml four-necked flask equipped with a serpentine reflux condenser, an electric stirrer, a constant pressure dropping funnel and an acid absorption tower.

[0037] Weigh 15g of aluminum nitrate nonahydrate and dissolve it in 180g of water. Under stirring conditions, slowly drop the aluminum nitrate solution into phenylphosphine dichloride at a temperature range of 5-10°C, adjust the pH to 2-6, heat to 60°C, and react at constant temperature for 1 hour to obtain a white precipitate, filter, wash, Drying can get white powder product aluminum phenyl phosphinate. The yield was 90.1%.

Embodiment 3

[0039] Add 21.48 g of phenylphosphine dichloride to a 500 ml four-necked flask equipped with a serpentine reflux condenser, an electric stirrer and an acid absorption tower.

[0040] Weigh 15g of aluminum nitrate nonahydrate and dissolve it in 150g of water. Under the condition of stirring, slowly drop the aluminum nitrate solution into the phenylphosphine dichloride in the temperature range of 5-10°C. After dropping, adjust the pH to 2-6, heat to 65°C, and react at constant temperature for 2 hours to obtain a white precipitate, filter , washing, and drying to obtain a white powder product, aluminum phenylphosphinate. The yield was 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com