Method for achieving fast cultivation of shortcut nitrifying granule sludge

A granular sludge and short-range nitrification technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of long start-up time, insufficient stability and efficiency of anaerobic granular sludge technology. High operating temperature and other problems, to achieve the effect of accelerating the granulation speed, improving the compactness, and improving the settlement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

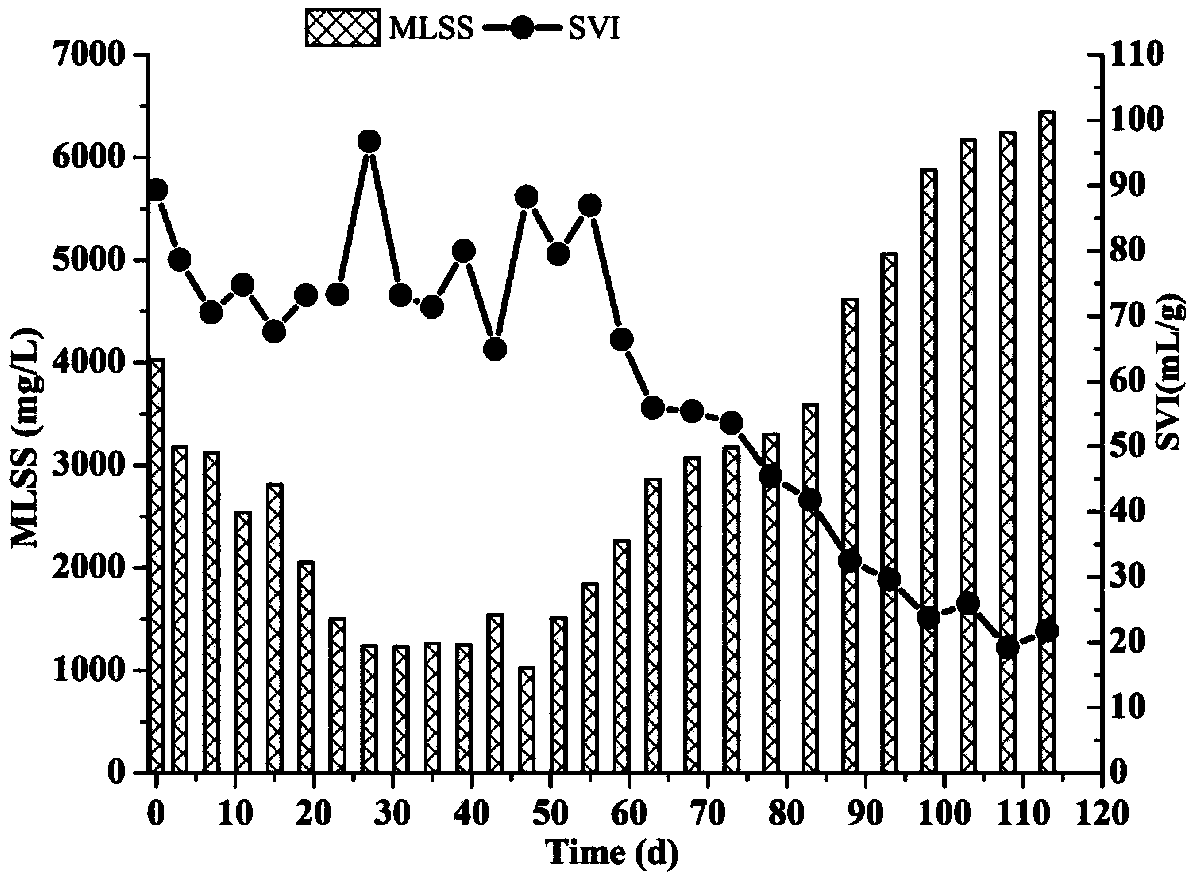

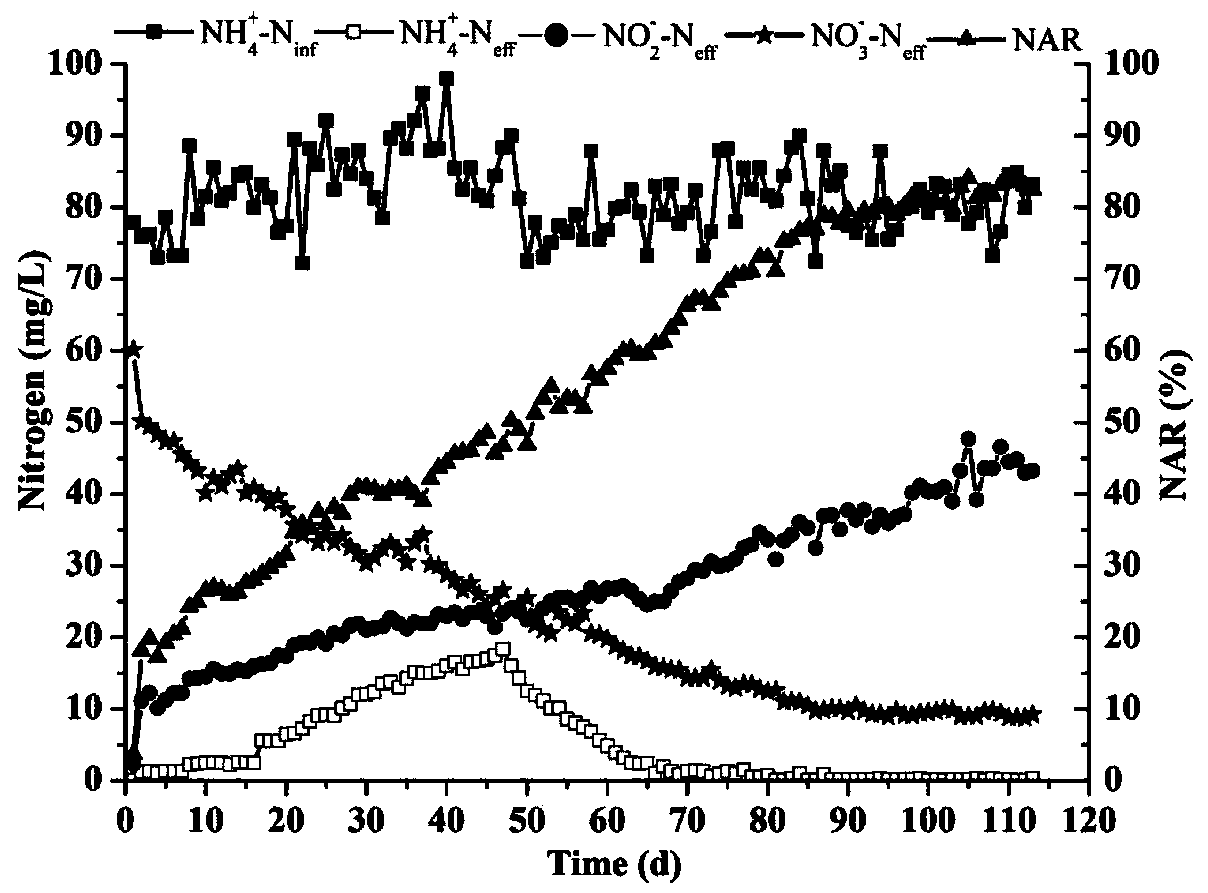

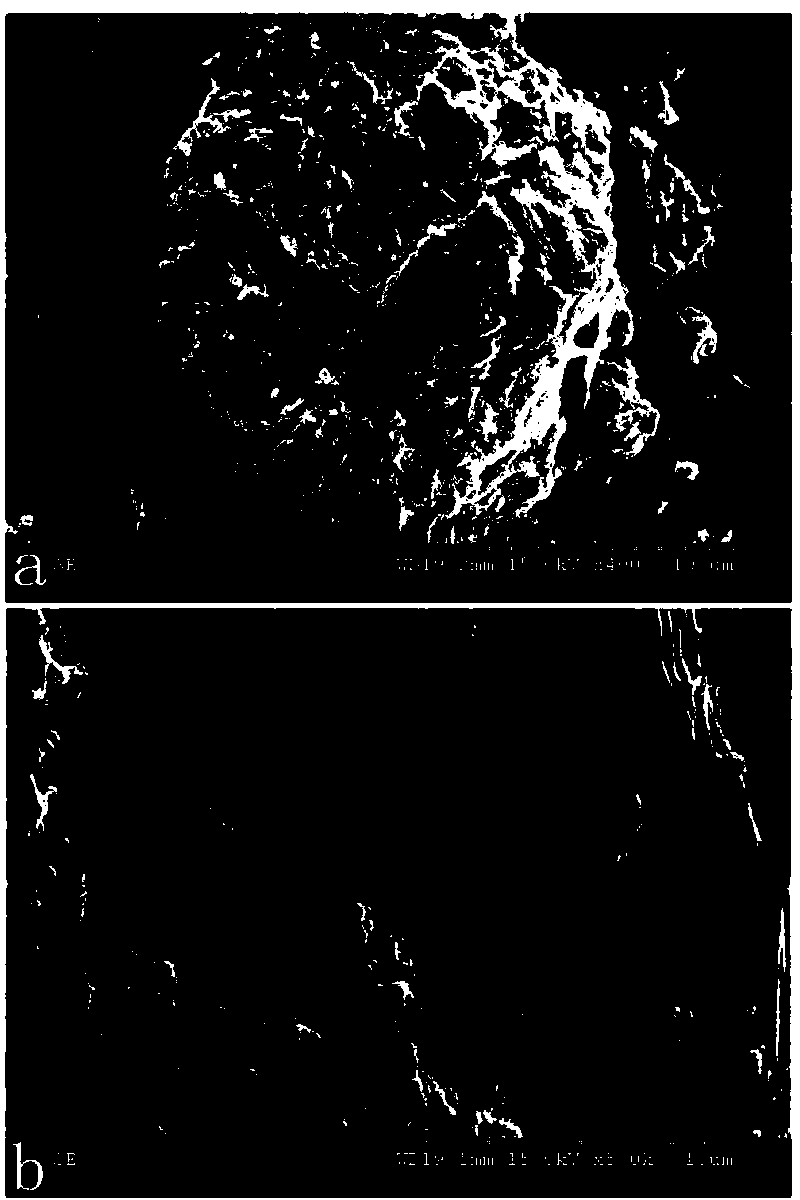

Embodiment 1

[0025] SBR reactor is adopted, with a height of 50cm, a diameter of 23.5cm, and an effective volume of 21L. It is made of plexiglass. A row of sampling ports with a spacing of 10cm is set on the vertical direction of the reactor wall, and a sludge discharge pipe is provided at the bottom. The drainage ratio 60%. The rubber microporous aeration disc is used as the aerator, and the air blowing is used for aeration, and the rotameter controls the aeration volume to keep it constant at 1L / h. The temperature in the reactor is controlled by a temperature controller and kept at 25-28°C. The operation of the SBR reactor realizes the automatic control of the reaction process through the time program controller, and runs 3 cycles a day, each cycle is 8h. The influent is artificially simulated domestic sewage, with sodium acetate as the organic carbon source, and the corresponding COD concentration is 400mg / L, NH 4 + -N concentration is 80mg / L. The MLSS of the inoculated sludge was 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com