Two-stage rotational-flow air flotation separator

A cyclone air flotation and separator technology, which is used in liquid separation, separation methods, flotation water/sewage treatment, etc., can solve the problems of inability to meet the requirements of oily sewage treatment, large equipment volume, increased investment and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of this patent will be described in further detail below in conjunction with the accompanying drawings.

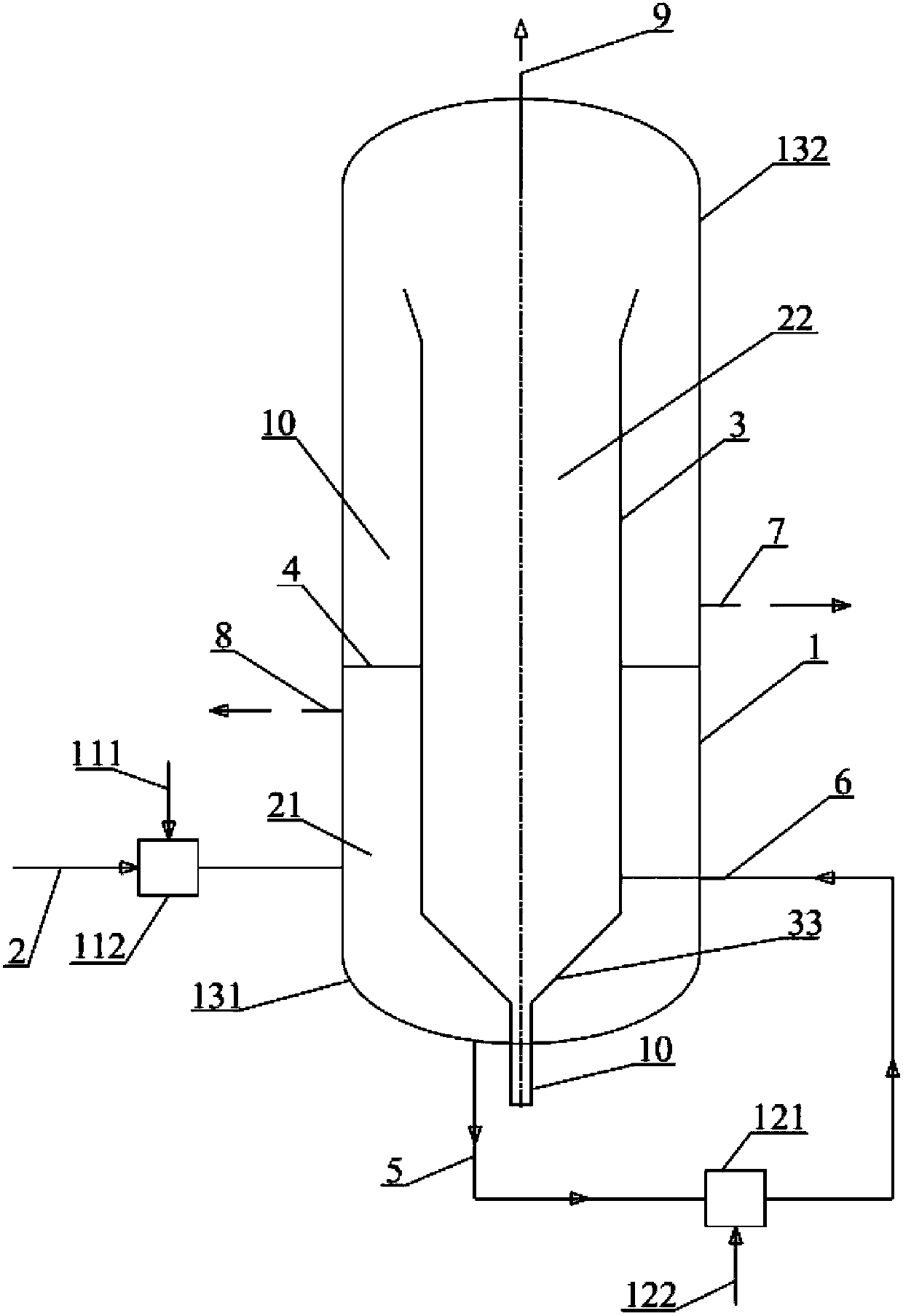

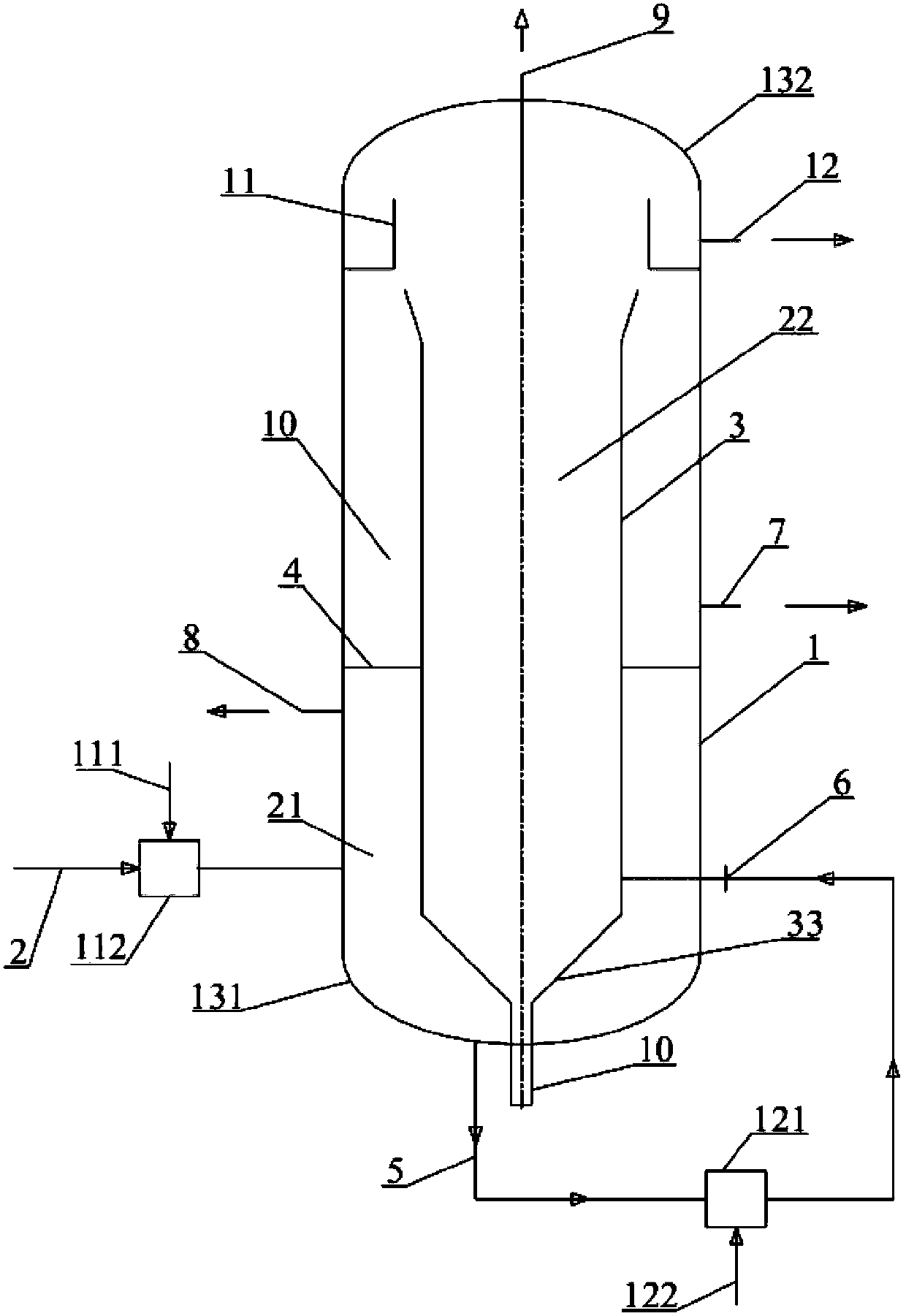

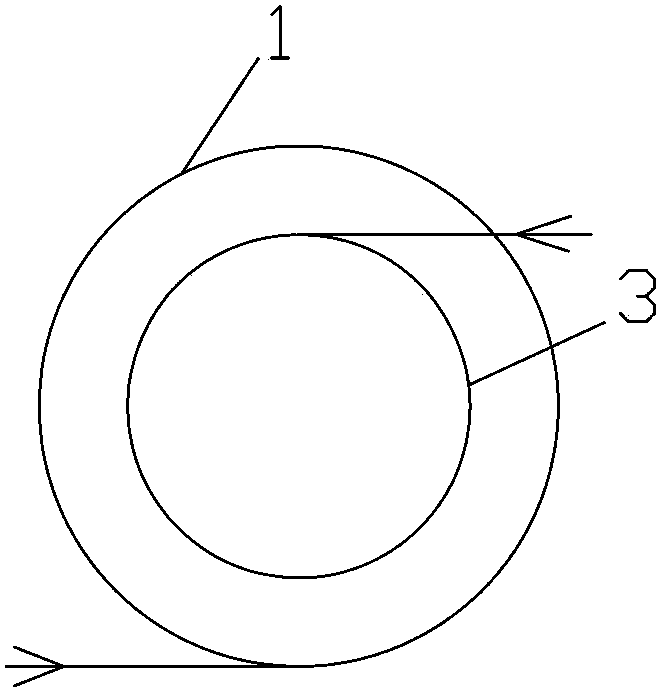

[0020] Such as figure 1 As shown, a two-stage cyclone air flotation separator includes a tank body 1, a primary water inlet 2, an inner cylinder 3, a partition 4, a primary water outlet 5, a secondary water inlet 6, and a secondary water outlet 7 , the first-level scum outlet 8, the second-level scum outlet 9 and the sewage outlet 10. The inner cylinder 3 is coaxially arranged with the tank body 1, and the tank body 1 is divided into a primary separation area and a secondary separation area by the inner cylinder 3, and a A partition 4, which divides the space between the inner wall of the tank body 1 and the outer wall of the inner cylinder 3 into a lower primary flotation zone 21 and an upper secondary flotation zone 22 that are independent and sealed up and down, The partition 4 is set at a position 1 / 3 to 1 / 2 of the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com