Functional composite nutrient enrichment leisure food and making method

A nutrition-fortified and leisure food technology, applied in food preparation, food science, application, etc., can solve the problems of difficult preservation, moth-eaten, perishable deterioration, etc., and achieve the effects of easy digestion and absorption, complementary processing characteristics, and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

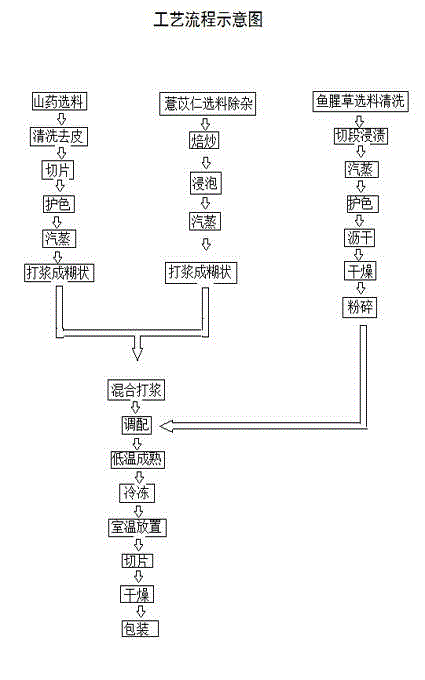

Method used

Image

Examples

Embodiment 1

[0072] (1) Selection of yam materials: choose fresh yams that are meticulous and uniform, free from bruises, pests, rot, and mildew spots;

[0073] (2) Cleaning and peeling: remove the yam skin with a scraper and rinse with water;

[0074] (3) Slicing: Cut the cleaned and peeled Chinese yam into slices with a thickness of 2-3mm with a stainless steel knife;

[0075] (4) Color protection: immerse the yam slices in the color protection solution prepared by mass fractions of 1.5g / 100ml salt, 0.25g / 100ml citric acid and 0.25g / 100ml sodium erythorbate, the ratio of yam to color protection solution The ratio is 1:3, so that the yam is fully submerged, the color protection time is 3 hours, and drained;

[0076] (5) Steaming: steam the yam slices after color protection for 1 hour when the steam volume of the water boils reaches the maximum;

[0077] (6) Beating: Put the steamed yam slices in a beater and mash them into a paste.

[0078] For every 100kg of freshly peeled and color-p...

Embodiment 2

[0108] 3. Deployment: Add 21kg of Houttuynia cordata powder, 7g of nutritional enhancer (weight ratio: zinc gluconate: ferrous lactate=2:3) and 120kg of sweetener (weight ratio: Xylitol: lactose: honey = 20:4:5), sour agent 4kg (citric acid) and loosening agent 0.8kg (weight ratio: sodium bicarbonate: sodium bitartrate = 2:1), fully stirred evenly to obtain Mixed material 245.807 kg;

[0109] 4. Low-temperature maturation: Knead the mixed material into a cylindrical strip with a weight of 0.5 kg, and mature it at 4°C for 48 hours to obtain the clinker;

[0110] 5. Freezing: freeze the mature material at -18°C for 48 hours to obtain the frozen material;

[0111] 6. Place at room temperature: place the frozen material at 20°C~25°C for 2 hours to obtain a semi-finished product;

[0112] 7. Slicing: Cut the semi-finished product into thin slices of about 3mm, uniform in thickness, and spread it on a stainless steel screen to get semi-finished thin slices;

[0113] 8. Drying: Dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com