Calibration test stand for performances of grain loss monitoring sensor of combined harvester

A technology for monitoring sensors and combine harvesters, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of vibration interference, complex operating environment, and calibration equipment that cannot truly simulate the installation location of grain loss monitoring sensors. problems, to achieve the effect of improving stability and ensuring the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

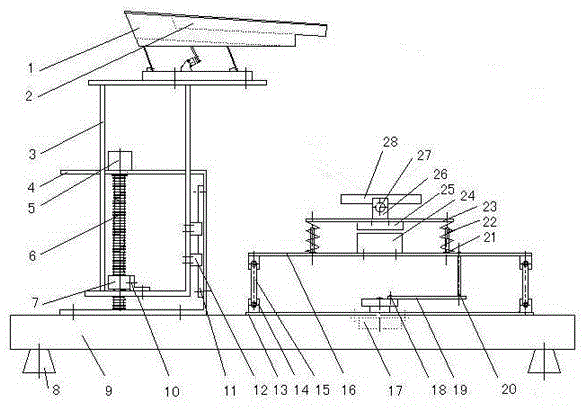

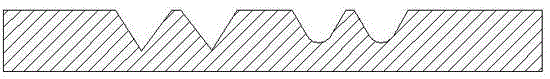

[0011] combine figure 1, the feeding device 1 is an electromagnetic vibration feeding device, and the electromagnetic vibration feeding device controls the feeding speed of the feeding device 1 by controlling the pull-in frequency of the electromagnet of the electromagnetic vibration feeding device through a supporting electric controller; the chute 2 is welded A double-layer feeding structure is formed on the trough wall of the feeding device 1; the slideway structure of the chute 2 is as follows: in the section perpendicular to the direction in which the grains slide, the cross-sectional shape of the slideway is semicircular or V-shaped. The feeding device 1 is fixed on the lifting platform 3 by bolts; the fixed bracket 4 is a structure made of aluminum alloy plates, and the width is the same as that of four sections of aluminum alloy profiles through right-angled connection codes, T-bolts and square nuts. The width of the formed rectangular frame base 9 is equal, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com