Method of obtaining X80 steel grade two phase organization large deformation pipeline steel

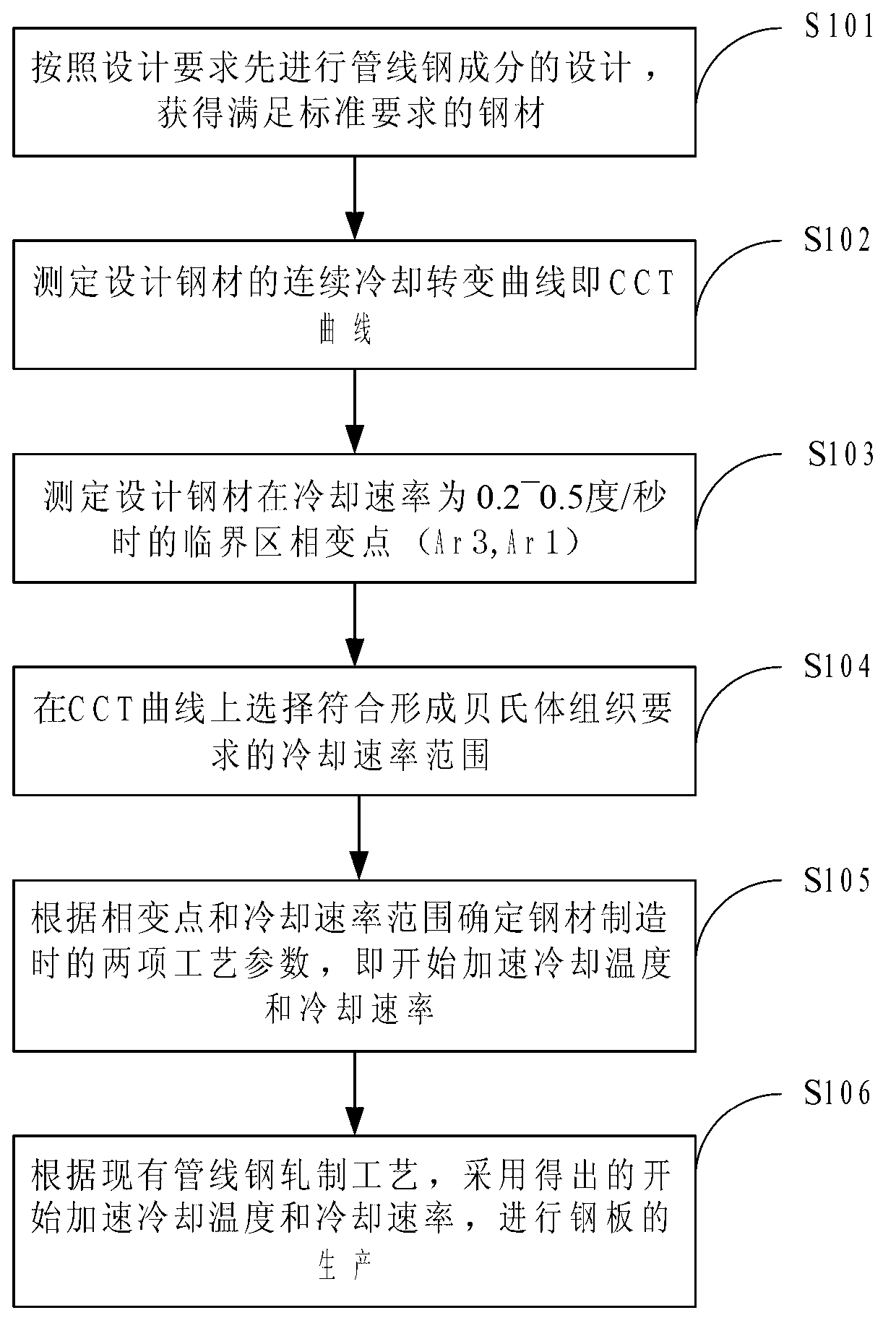

A dual-phase microstructure and pipeline steel technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problem of duplex microstructure photos and stress-strain curves without providing manufacturing process plans, large-deformation duplex microstructures, production methods and The technology has not been publicly reported and other issues, to achieve the effect of strong promotion and application value, high deformation strengthening index, and large deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (X80

[0047] Example (X80 steel grade large deformation pipeline steel):

[0048] Step 1: Determine the chemical composition of the steel (as shown in the table below):

[0049]

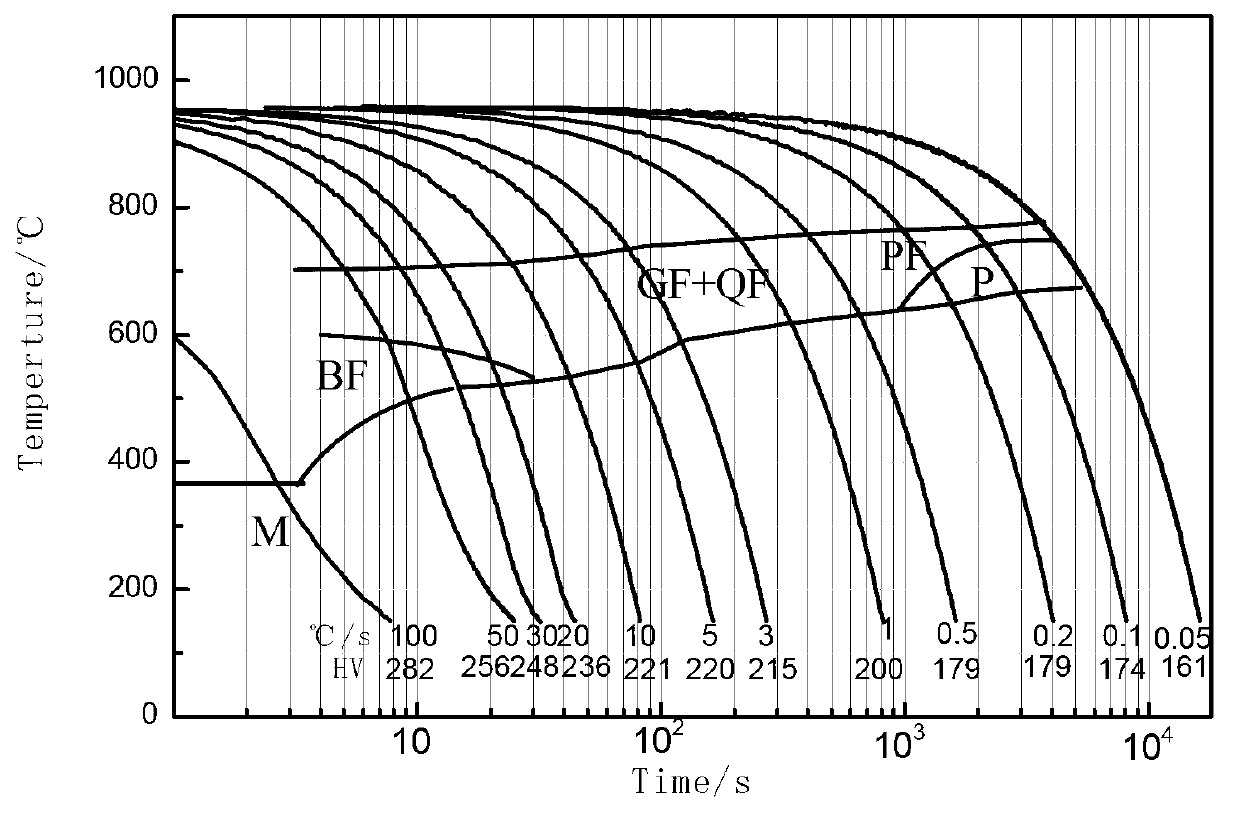

[0050] Step 2: The continuous cooling transformation curve of steel, such as figure 2 shown;

[0051] Step 3. Determine the phase transition point range corresponding to the test steel at a cooling rate of 0.3 degrees per second (790-700°C);

[0052] Step 4: According to the continuous cooling transformation curve, it is determined that the accelerated cooling rate of this kind of steel to obtain the dual-phase structure is in the range of 65-95°C / s;

[0053] Step 5. Determine the starting cooling temperature of the steel as 745° C. and the cooling rate as 80° C. / s according to the determined phase transition point and cooling rate range;

[0054] Step 6, using the accelerated cooling process determined in step 5 to manufacture the steel.

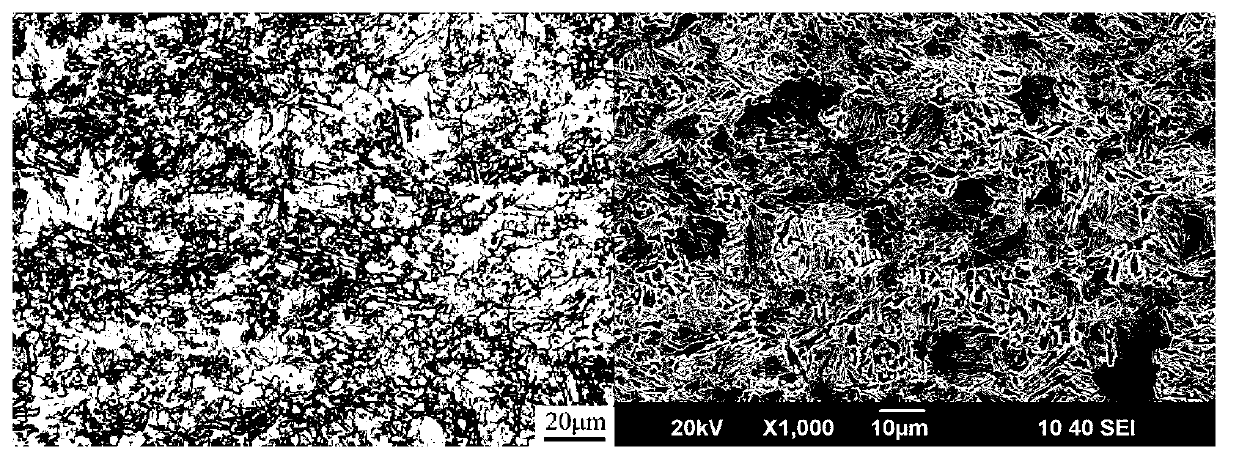

[0055] The optical microstructure and scanning electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com