A method of using a large deformation prestressed hydraulic expansion bolt

A hydraulic expansion and prestressing technology, which is applied in the installation of anchor rods, earthwork drilling, mining equipment, etc., can solve the problems of not considering the radial prestressing of the rod body, failing to meet the support requirements of deep rock mass engineering, etc., and achieve simple structure , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The practice of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the invention, only for example. At the same time, the advantages of the present invention will be apparent from the advantages and easy to understand.

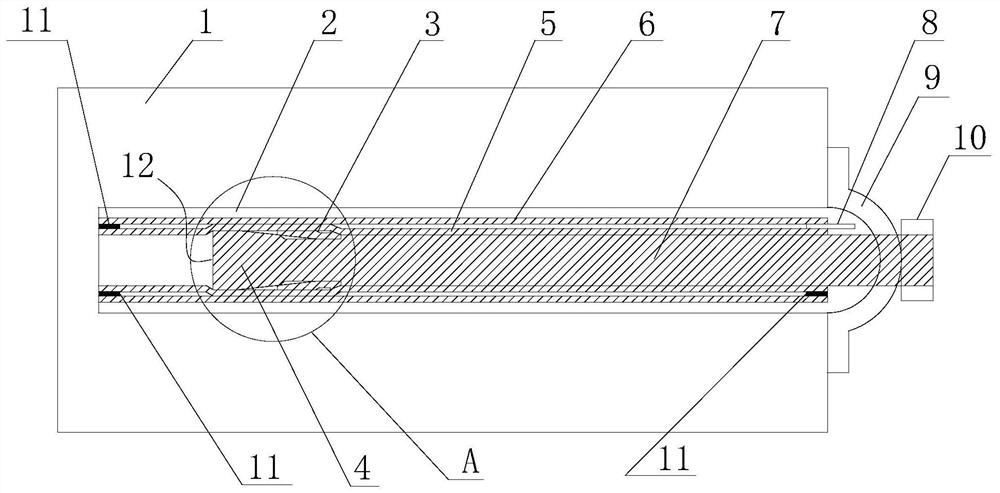

[0054] Referring to the drawings: The method of using a large deformation prestressed hydraulic expansion anchor includes the following steps.

[0055] Step 1: Forming a drilling 2 on the surrounding rock 1;

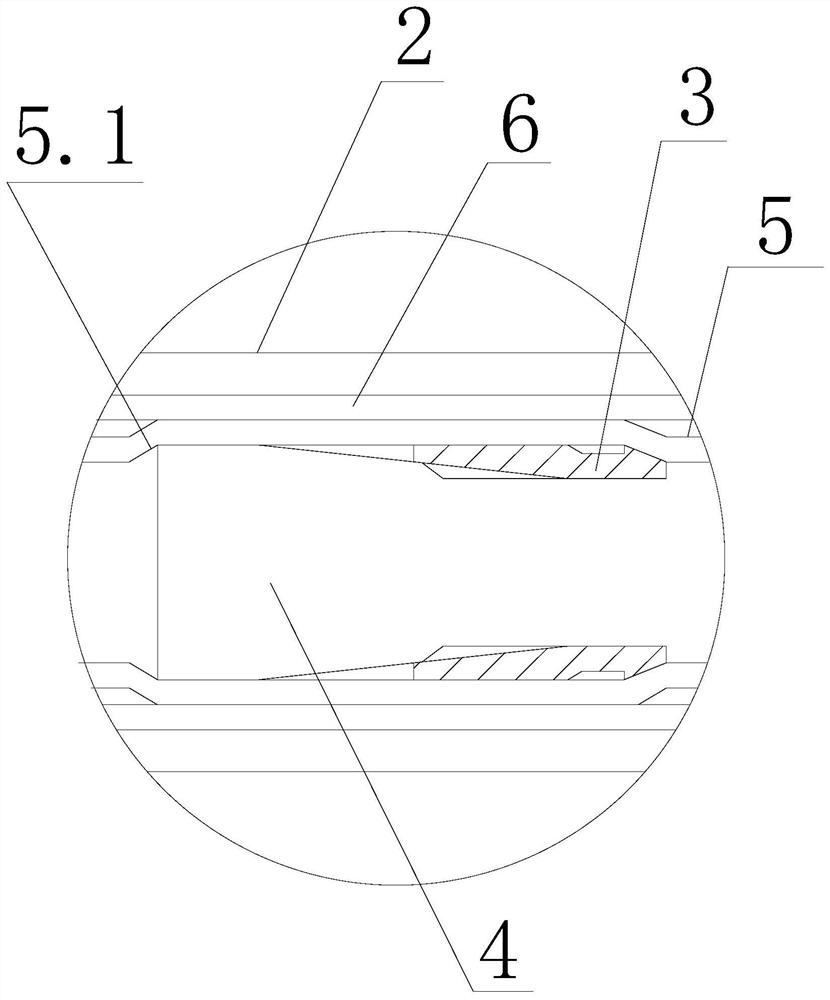

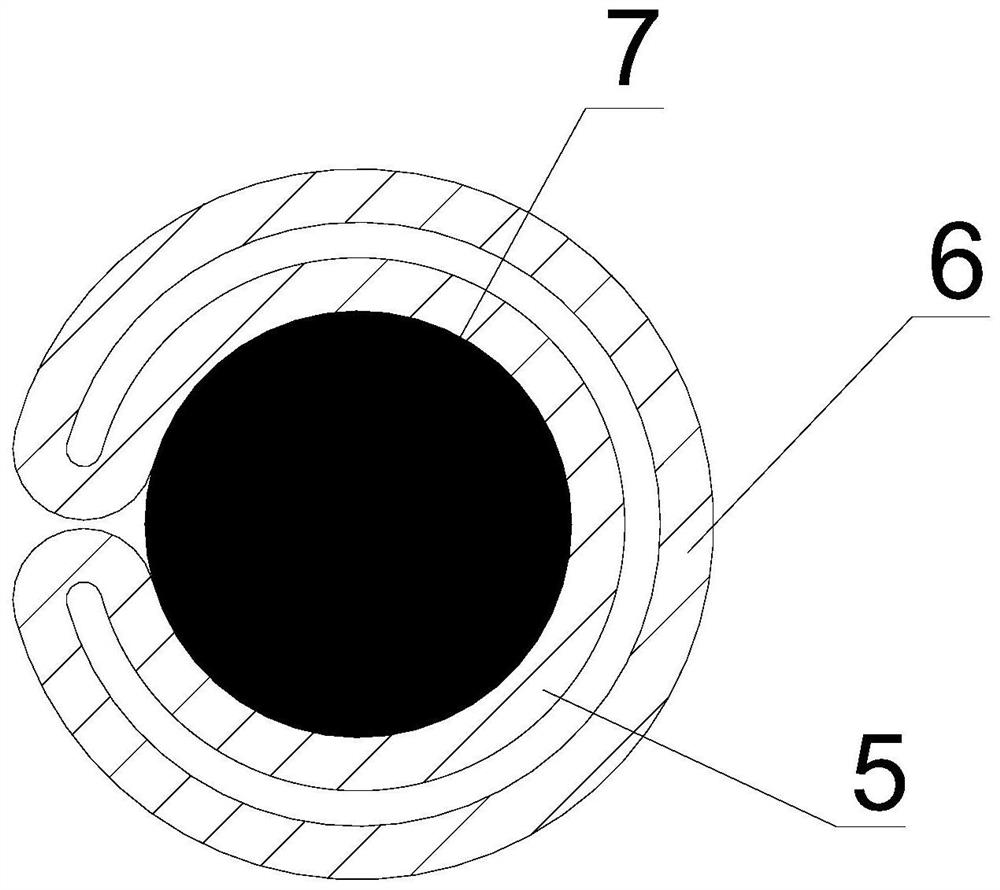

[0056] Step 2: Put the large deformation prestressed hydraulic expansion anchor into the drilling 2, by the gap between the hydraulically expanded inner casing 5 and the hydraulic expansion housing 6, so that the hydraulic expansion housing 6 is close to the drilling hole 2 The hole wall, and the hydraulic expansion inner casing 5 facing the inner rod structure 12, securing the inner rod structure 12 in the drilling 2 by the tray 9 and the nut 10 to complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com